Mr Ed

Established Member

Hello All

I've not been posting here for some considerable time, but I did read the recent thread on the ATC course and enjoyed it, so I thought I would reciprocate by sharing my pictures of the Dutch Tool Chest course the following week. These are all from Instagram, which I used to capture things as the course went along and then completing the build once I got home.

You need to make a tool chest to take your tools to a tool chest making course

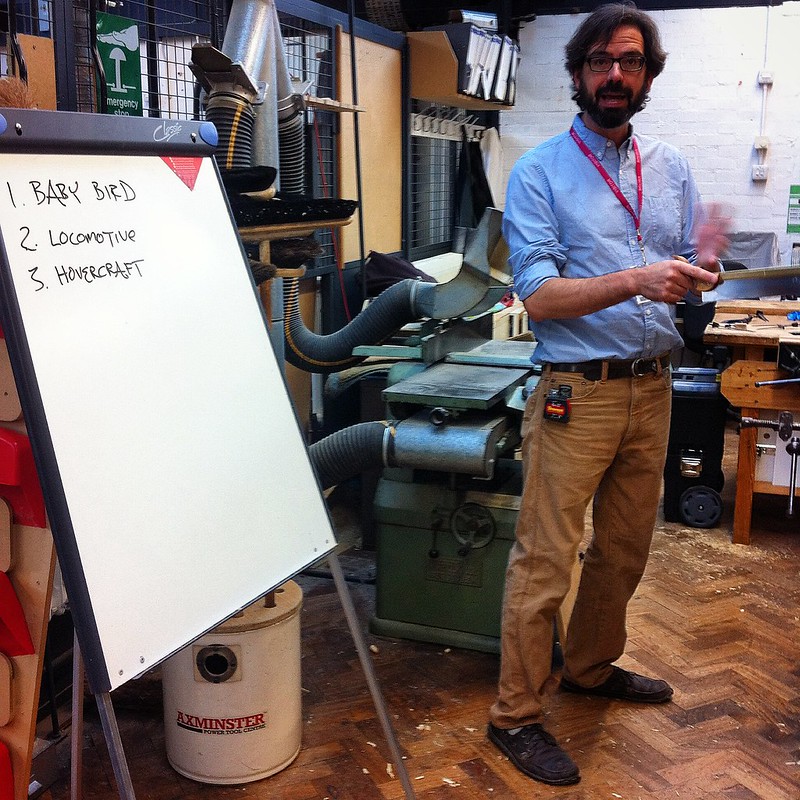

Ready to get started

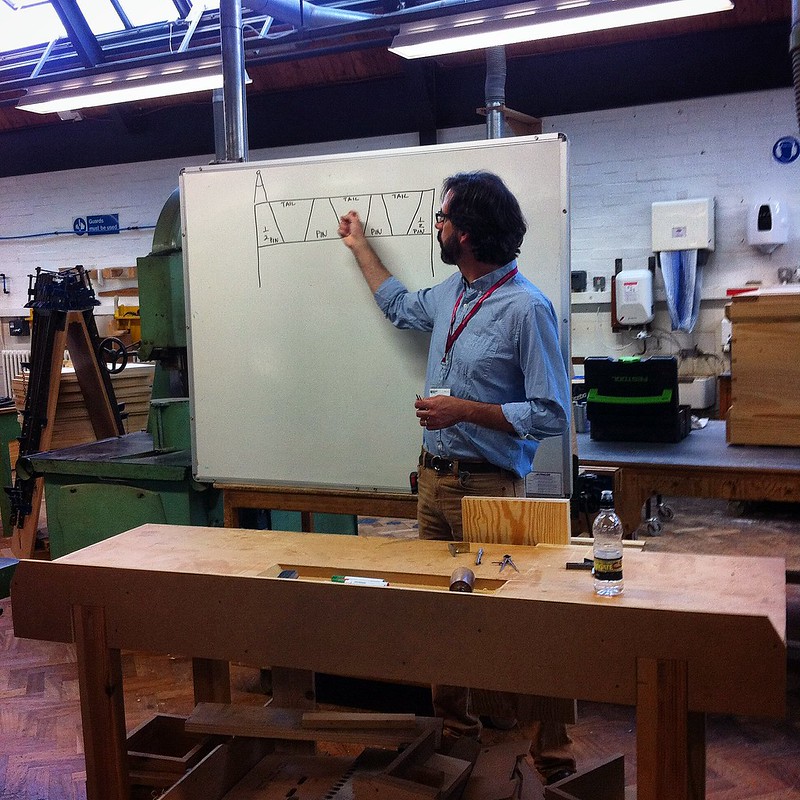

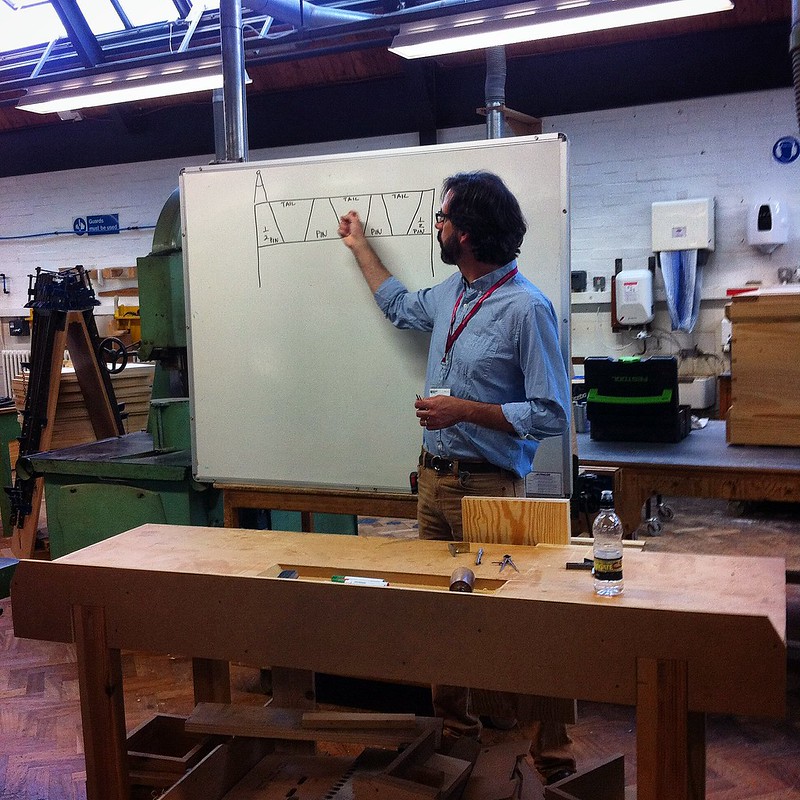

Quick dovetail tutorial

Marking out

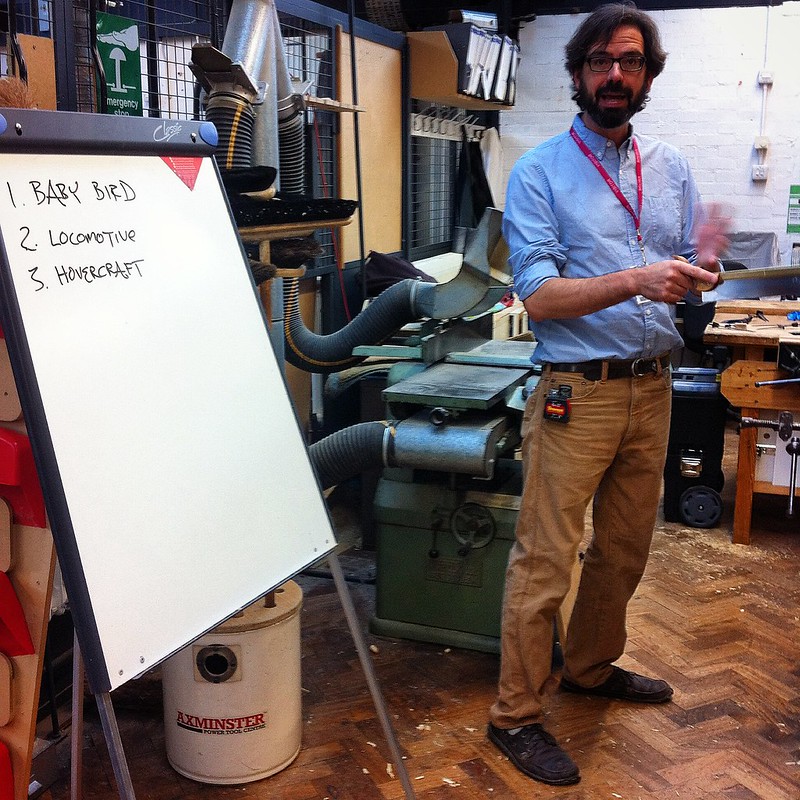

Sawing tutorial

Sawing

Coping

Cleaning the faces up

The Schwarz dovetailing

More coping

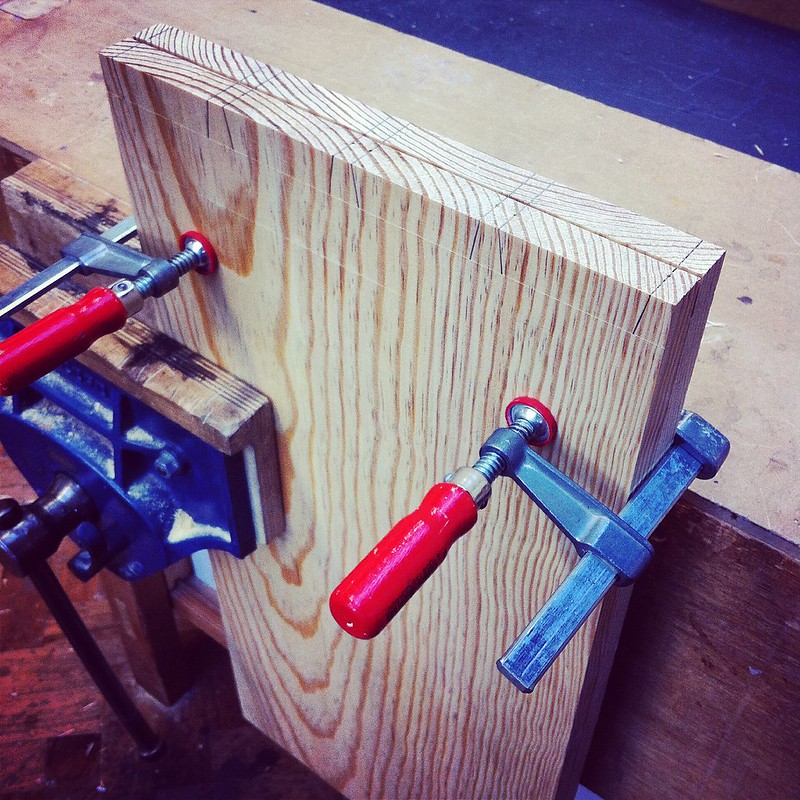

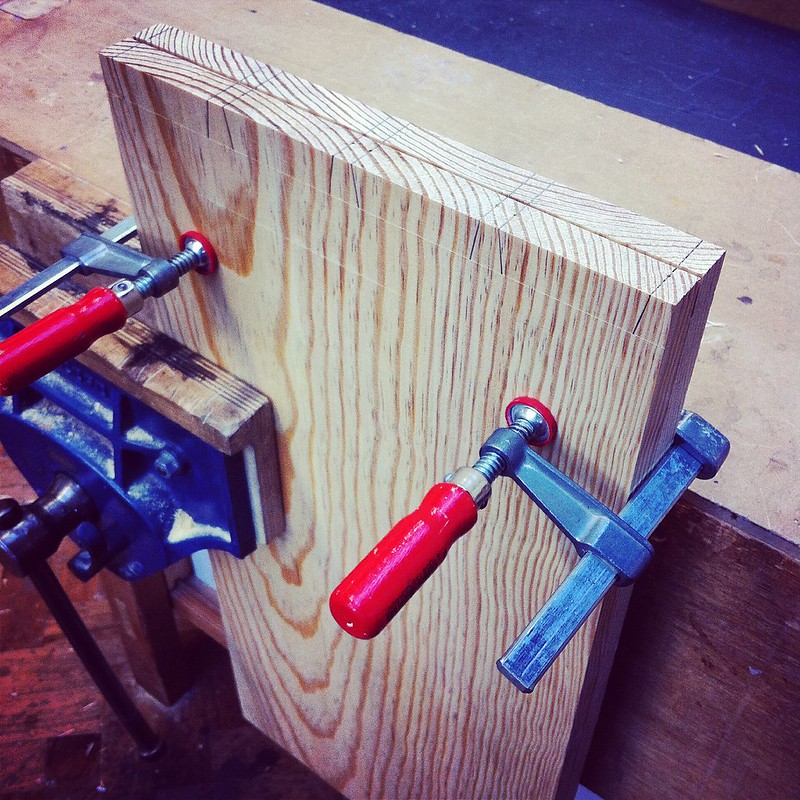

In the clamps at the end of day one

Cleaning up after gluing

Fitting the shelf

Beading with Mr Schwarz's Clarke and Williams side bead

Front lip fitted

Nailing on the back

With the fall front fitted

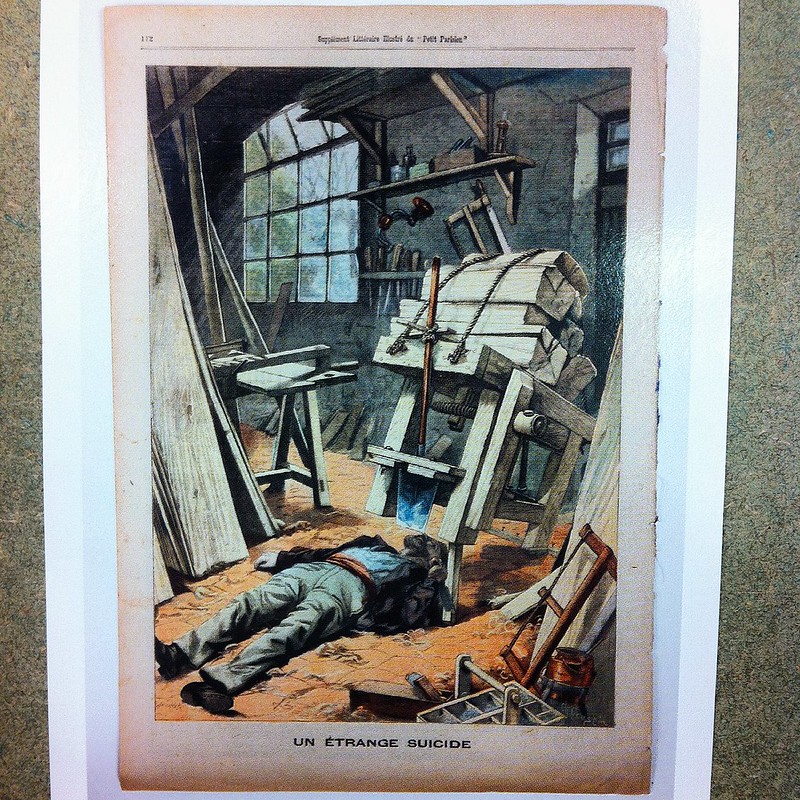

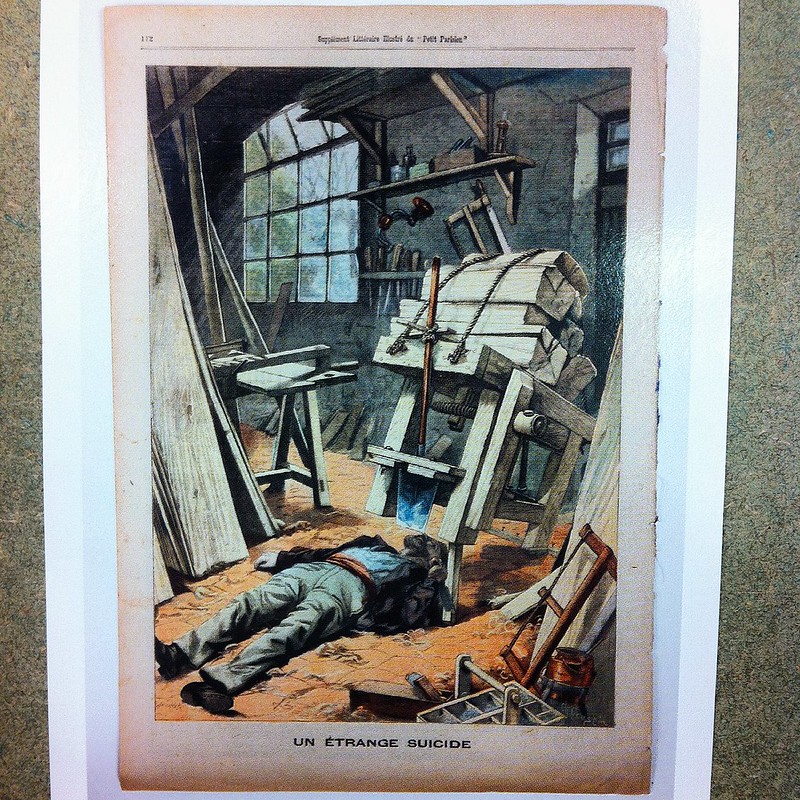

Has it come to this?

Back home in the workshop

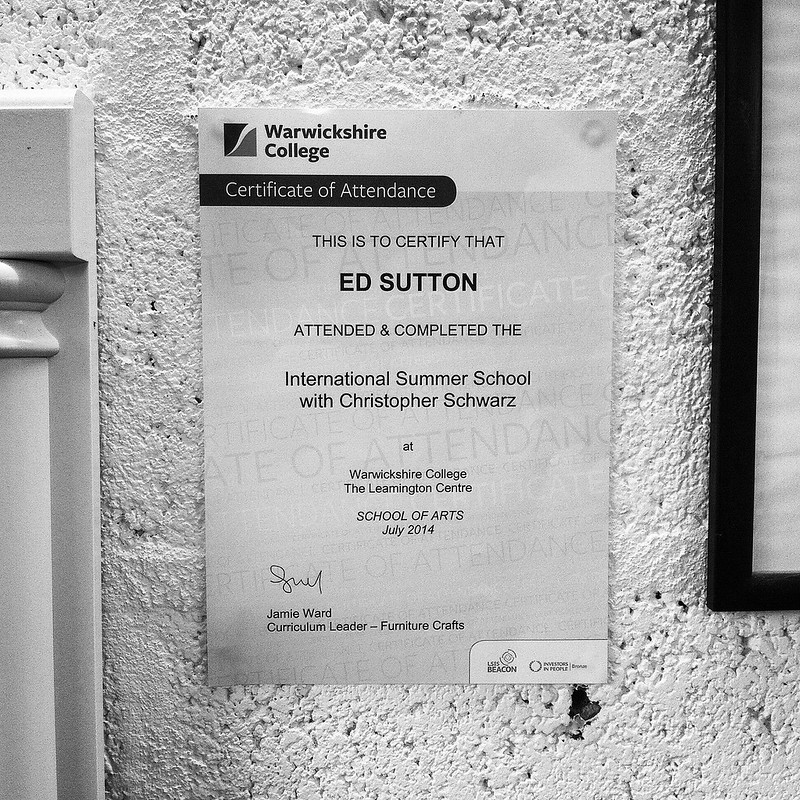

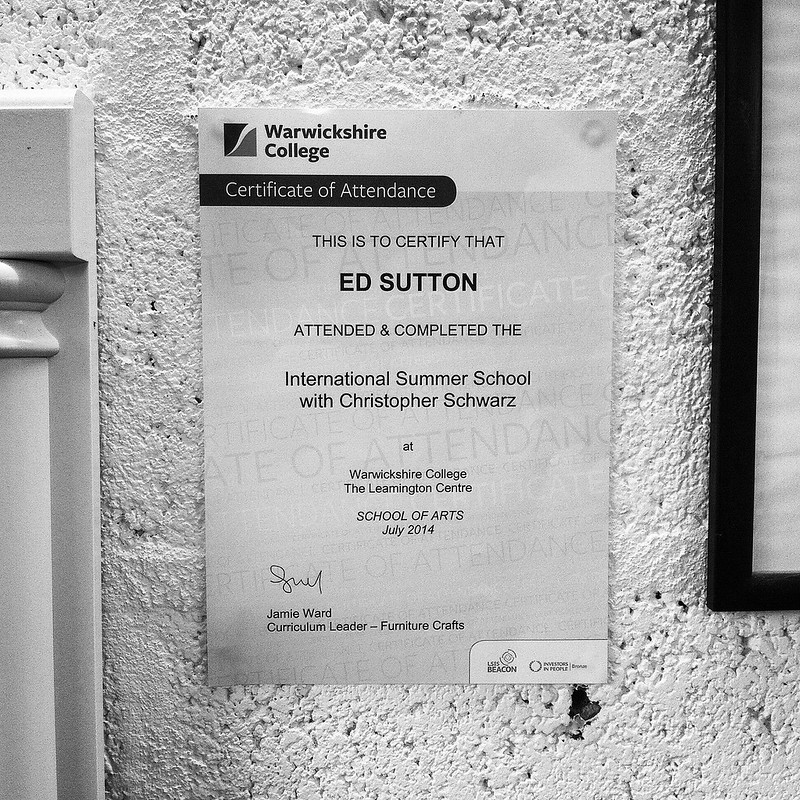

All about the certificate

Cleaning up the dovetails

Fitting the battens to the fall front

A little adjustment

Skids on the bottom of the case

Coming together

Ripping the breadboard ends for the top

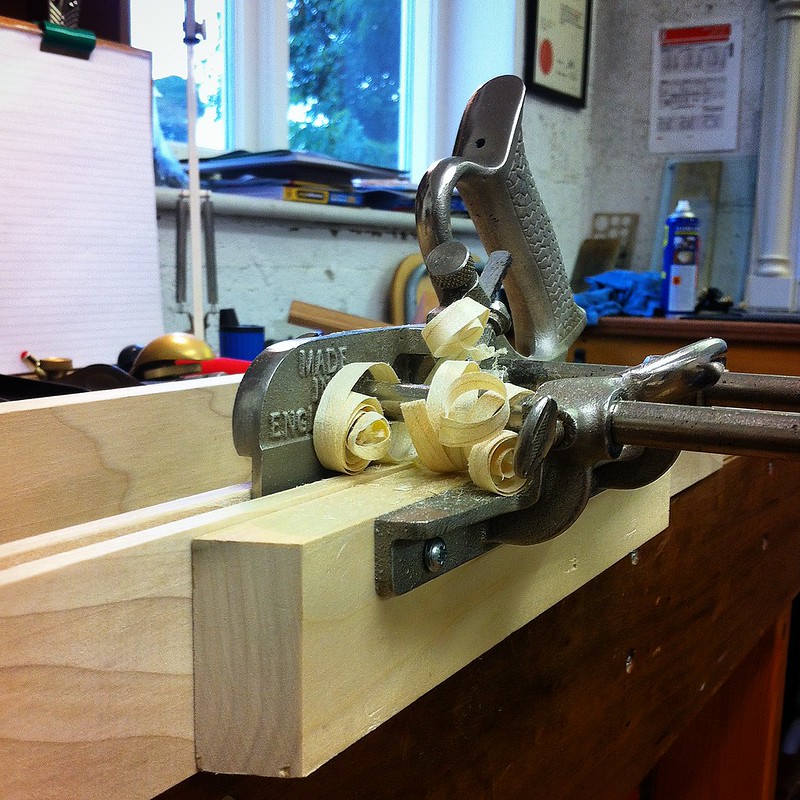

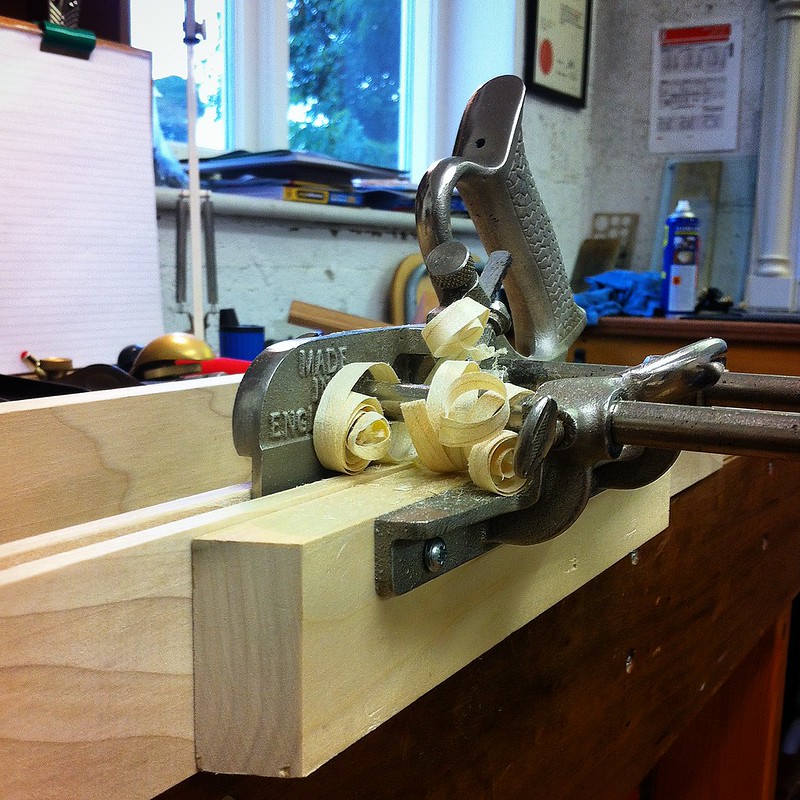

Ploughing the groove

Fitting the breadboard ends with pegs

Hand planed thumbnail moulding on the lid

Fitting the hinges

Lid fitted

Fitting the handles

Fitting the hasp

Done (apart from some paint and the internal fittings)

And finally, sitting happily in its new home

Hope that's of interest to someone

Cheers, Ed

I've not been posting here for some considerable time, but I did read the recent thread on the ATC course and enjoyed it, so I thought I would reciprocate by sharing my pictures of the Dutch Tool Chest course the following week. These are all from Instagram, which I used to capture things as the course went along and then completing the build once I got home.

You need to make a tool chest to take your tools to a tool chest making course

Ready to get started

Quick dovetail tutorial

Marking out

Sawing tutorial

Sawing

Coping

Cleaning the faces up

The Schwarz dovetailing

More coping

In the clamps at the end of day one

Cleaning up after gluing

Fitting the shelf

Beading with Mr Schwarz's Clarke and Williams side bead

Front lip fitted

Nailing on the back

With the fall front fitted

Has it come to this?

Back home in the workshop

All about the certificate

Cleaning up the dovetails

Fitting the battens to the fall front

A little adjustment

Skids on the bottom of the case

Coming together

Ripping the breadboard ends for the top

Ploughing the groove

Fitting the breadboard ends with pegs

Hand planed thumbnail moulding on the lid

Fitting the hinges

Lid fitted

Fitting the handles

Fitting the hasp

Done (apart from some paint and the internal fittings)

And finally, sitting happily in its new home

Hope that's of interest to someone

Cheers, Ed