Morning all. SWMBO has commissioned her next piece of furniture so I'm back again for some

advice/tips on re-creating this nested set of tables.

http://furnitureulike.co.uk/index.php?t ... t_id=32202

She wants them to have that "chunky look" and from the pics i'm guessing they're about 3" thick.

The dims i'm going to use for the outer table are about 36" x 15" x 3" x 18" (L x W x T x H)

with only two tables underneath. Given these dims that's just under 3.5cuft

The plan is to use Ash (cheap to fix mistakes!) with some kind of dark stain finish similar to

the pics.

It looked easy when i first saw it but then i sat down to plan how i was going to do it and i

just can't decide on how to actually make them !

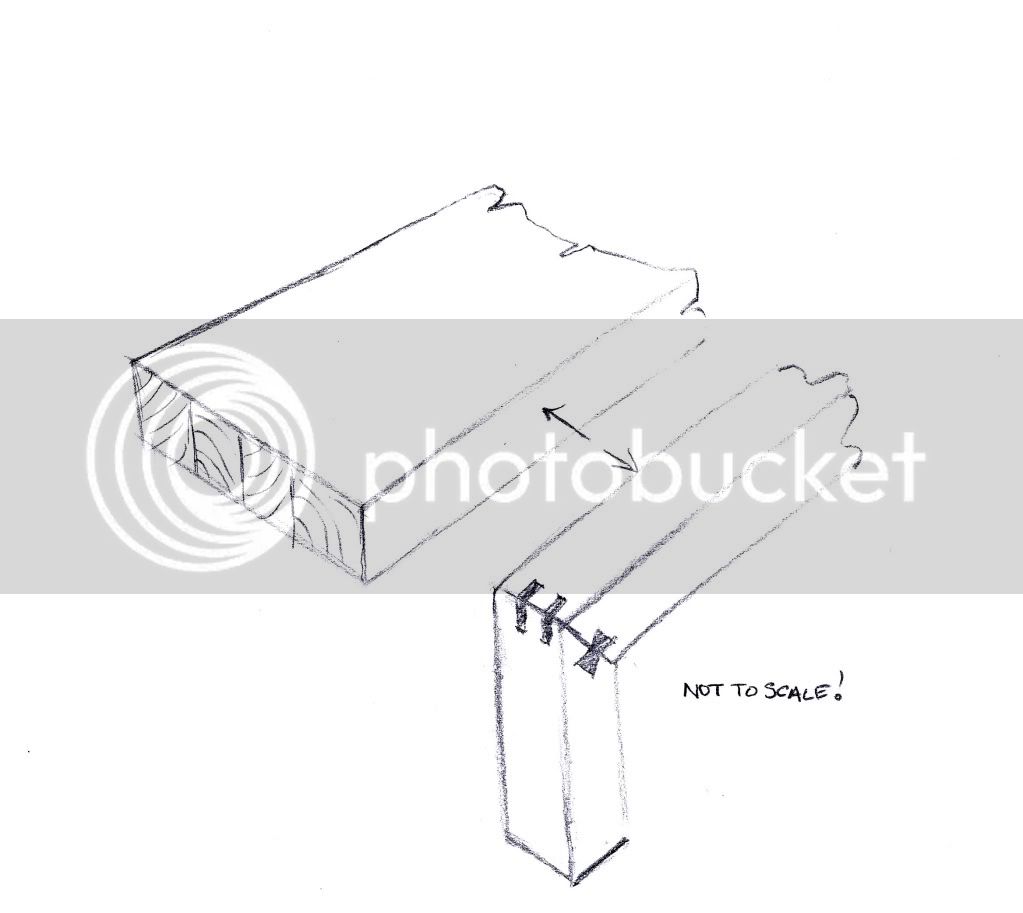

I could just joint and laminate loads of Ash, cut the mitres and biscuit/spline the bits

together. This seems relatively easy (might regret saying that) to do but but would require the

full 3.5cuft of Ash...plus wastage, Which is an awful lot and i'm guessing they're going to be

heavy.

The other idea i have is to create 3 or 4 "U" shaped pieces with half-lap joints from ply/mdf to

act as a frame, around which i attach the sides/fronts/backs/tops/etc

The sides/fronts/backs/tops/etc will be made from jointing the ash and could be only 1/2" thick,

saving a lot of timber. However, all those mitres scares me silly !

I just can't on how to proceed.

Any ideas/tips/advice would be gratefully appreciated.

furyJohn

advice/tips on re-creating this nested set of tables.

http://furnitureulike.co.uk/index.php?t ... t_id=32202

She wants them to have that "chunky look" and from the pics i'm guessing they're about 3" thick.

The dims i'm going to use for the outer table are about 36" x 15" x 3" x 18" (L x W x T x H)

with only two tables underneath. Given these dims that's just under 3.5cuft

The plan is to use Ash (cheap to fix mistakes!) with some kind of dark stain finish similar to

the pics.

It looked easy when i first saw it but then i sat down to plan how i was going to do it and i

just can't decide on how to actually make them !

I could just joint and laminate loads of Ash, cut the mitres and biscuit/spline the bits

together. This seems relatively easy (might regret saying that) to do but but would require the

full 3.5cuft of Ash...plus wastage, Which is an awful lot and i'm guessing they're going to be

heavy.

The other idea i have is to create 3 or 4 "U" shaped pieces with half-lap joints from ply/mdf to

act as a frame, around which i attach the sides/fronts/backs/tops/etc

The sides/fronts/backs/tops/etc will be made from jointing the ash and could be only 1/2" thick,

saving a lot of timber. However, all those mitres scares me silly !

I just can't on how to proceed.

Any ideas/tips/advice would be gratefully appreciated.

furyJohn