Streepips

Established Member

Just received a shipment of Narex bevel edge chisels and first impressions are very good.

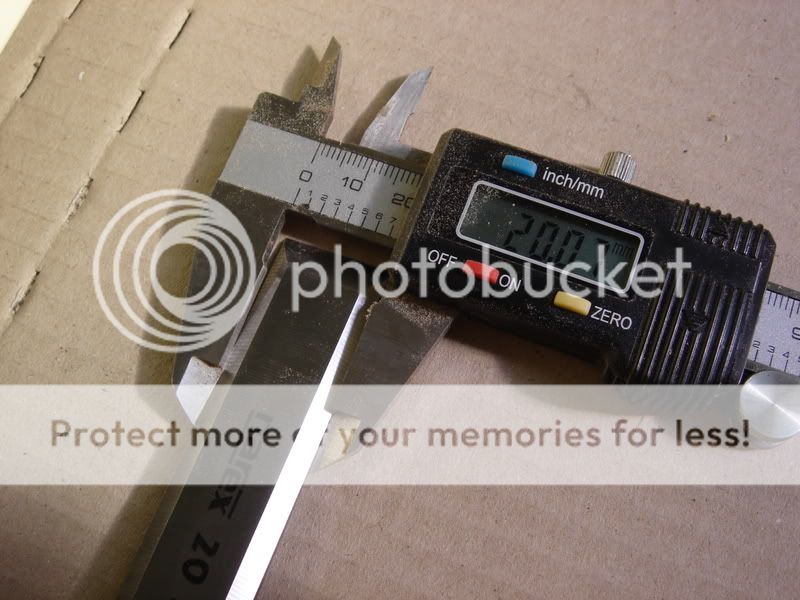

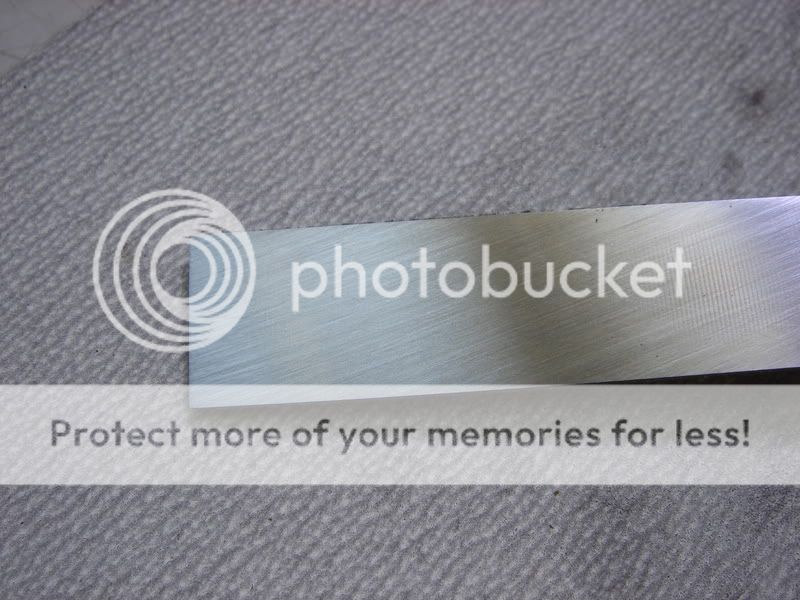

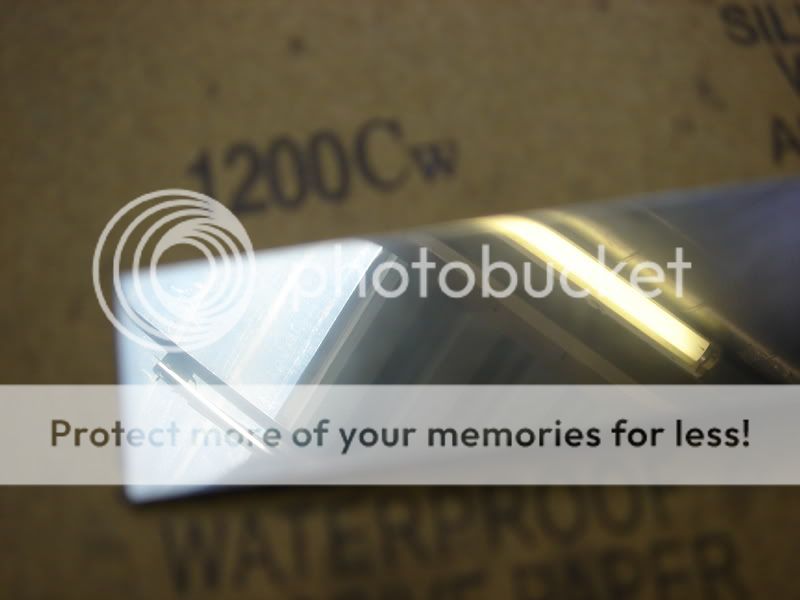

They are flat along both the width and length, ( No light through an engineers straight edge) have minimal fine grinding marks in the back and have a decent bevel and microbevel and edge on them straight out of the box, Tang type with beech handle, ferrules above the tang and also at the top for mallet work, nicely balanced and about midweight for a chisel of this type. handle has slight flats to stop bench rolling and help the ergonomics, and finished in a light satin/matt coat of something unobstrusive.

Looks like a minimal flatting will sort the backs out then I will hone them and try them out. The actual steel looks very fine grained.

I considered Ashley Iles, R Sorby, even Two Cherries and all the usual contenders but noted quite a few grumbles about these ranges and of course the price is not cheap, especially compared to less well known brands such as Narex.

The Narex get 59>61 rc hardness, which is as far as you can go without getting brittle, and there are some good reviews from European/American users.

Lee Valley Tools and Highland Tools sell Narex in USA.

Last set of chisels I got was a Marples splitproof and these were disappointing all round so up to now I have been using old Footprint, Bahco, Marples, Stanley, etc, all of which take and hold a good edge and take some clout.....mainly because the newest among them is at least 25 years old !...These are used for site work though and I wanted a decent set for benchwork.....I eventually got the Marples something like with a good flatting on the back, from 60 grit successive through to 1500, mirror finish after approx an hour and a half each, and I have a Scheppach 2500 whetstone with leather strop wheel so I can get an edge that cuts floating paper,however the marples just wont hold it, either dulling off rapidly or just nicking out too easily.

So I thought I would explore new territory, hence the Narex...Hope they perform as good as they look they might! Plenty to have a go at, 6,8,10,12,14,16,18, 20, 22. 26, 30, 32 and 40mm in the set.. Overkill I know, just felt like it !

and yes I know they are moly-chrome steel, not high carbon, hammer forged, etc etc, I did my research and made my decision and if anyone is interested in how I get on with them or would like a pic of them let me know.....

They are flat along both the width and length, ( No light through an engineers straight edge) have minimal fine grinding marks in the back and have a decent bevel and microbevel and edge on them straight out of the box, Tang type with beech handle, ferrules above the tang and also at the top for mallet work, nicely balanced and about midweight for a chisel of this type. handle has slight flats to stop bench rolling and help the ergonomics, and finished in a light satin/matt coat of something unobstrusive.

Looks like a minimal flatting will sort the backs out then I will hone them and try them out. The actual steel looks very fine grained.

I considered Ashley Iles, R Sorby, even Two Cherries and all the usual contenders but noted quite a few grumbles about these ranges and of course the price is not cheap, especially compared to less well known brands such as Narex.

The Narex get 59>61 rc hardness, which is as far as you can go without getting brittle, and there are some good reviews from European/American users.

Lee Valley Tools and Highland Tools sell Narex in USA.

Last set of chisels I got was a Marples splitproof and these were disappointing all round so up to now I have been using old Footprint, Bahco, Marples, Stanley, etc, all of which take and hold a good edge and take some clout.....mainly because the newest among them is at least 25 years old !...These are used for site work though and I wanted a decent set for benchwork.....I eventually got the Marples something like with a good flatting on the back, from 60 grit successive through to 1500, mirror finish after approx an hour and a half each, and I have a Scheppach 2500 whetstone with leather strop wheel so I can get an edge that cuts floating paper,however the marples just wont hold it, either dulling off rapidly or just nicking out too easily.

So I thought I would explore new territory, hence the Narex...Hope they perform as good as they look they might! Plenty to have a go at, 6,8,10,12,14,16,18, 20, 22. 26, 30, 32 and 40mm in the set.. Overkill I know, just felt like it !

and yes I know they are moly-chrome steel, not high carbon, hammer forged, etc etc, I did my research and made my decision and if anyone is interested in how I get on with them or would like a pic of them let me know.....