Hi all

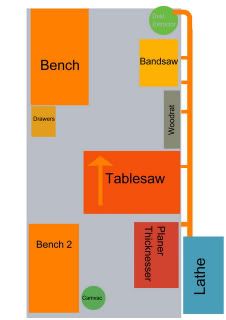

I saw one of my uncle's today and got round to talking about my workshop and he asked me if I had a lathe. I said, no, and he said 'do you want one?' I said YES PLEASE. I'm going to look at it in the next couple of weeks to see if I can fit it in (I'm sure I'll manage!)

My question is about dust extraction - I've just been updating my plumbed in system with a more powerful extractor and have placed my single motor Camvac on ebay to offset the cost of the new extractor. Not having ever used a lathe before I don't know whether it would be better to keep the Camvac and use it as a dedicated collector for the lathe or whether the plumbed in system could cope.

I have to decide quickly as the ebay auction is due to end on Friday!

Oh, the lathe is a Myford, I think ML7 - don't know anything about it apart from distance between centres is about 33 inches.

Looking forward to seeing it...especially as he's got some chisels I can have too

Anyone any advice on the dust extraction?

I saw one of my uncle's today and got round to talking about my workshop and he asked me if I had a lathe. I said, no, and he said 'do you want one?' I said YES PLEASE. I'm going to look at it in the next couple of weeks to see if I can fit it in (I'm sure I'll manage!)

My question is about dust extraction - I've just been updating my plumbed in system with a more powerful extractor and have placed my single motor Camvac on ebay to offset the cost of the new extractor. Not having ever used a lathe before I don't know whether it would be better to keep the Camvac and use it as a dedicated collector for the lathe or whether the plumbed in system could cope.

I have to decide quickly as the ebay auction is due to end on Friday!

Oh, the lathe is a Myford, I think ML7 - don't know anything about it apart from distance between centres is about 33 inches.

Looking forward to seeing it...especially as he's got some chisels I can have too

Anyone any advice on the dust extraction?