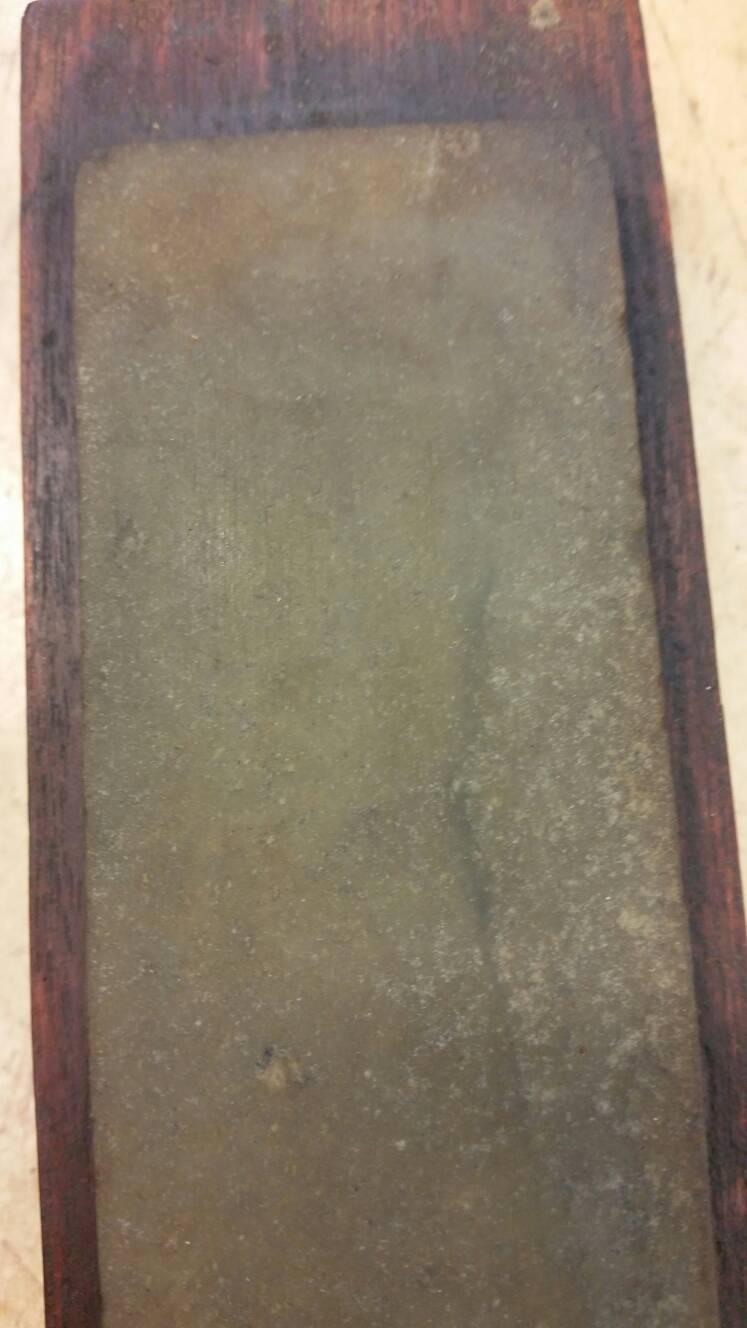

Years ago I picked this stone up from the boot sale and thought it could be my go to sharpening stone. It was my first ever sharpening stone.

A few of the old guys advised against it cause it was so fine. I ended up with a Norton combination.

All these years later and I think I've found a place for it. My diamond stone is 1200 and a Waterstone I like to use is so soft I quite often take nicks/chunks from it. I'm just wondering what it might be ? The surface has been freshened up with a diamond stone and seems to do a good job of refining the edge. I'd just like to know what it could be !

Cheers

Coley

Sent from my SM-G900F using Tapatalk

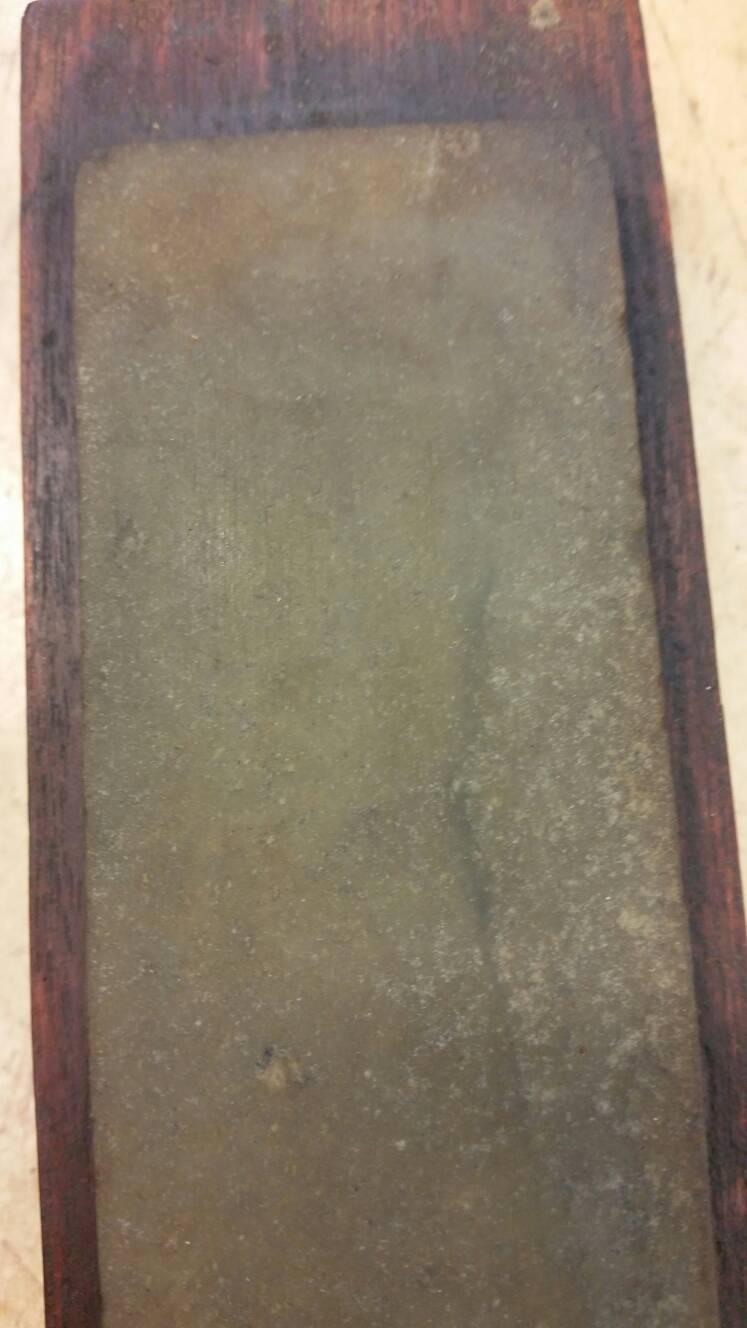

A few of the old guys advised against it cause it was so fine. I ended up with a Norton combination.

All these years later and I think I've found a place for it. My diamond stone is 1200 and a Waterstone I like to use is so soft I quite often take nicks/chunks from it. I'm just wondering what it might be ? The surface has been freshened up with a diamond stone and seems to do a good job of refining the edge. I'd just like to know what it could be !

Cheers

Coley

Sent from my SM-G900F using Tapatalk