I have a notebook I carry at all times and jot down every idea.

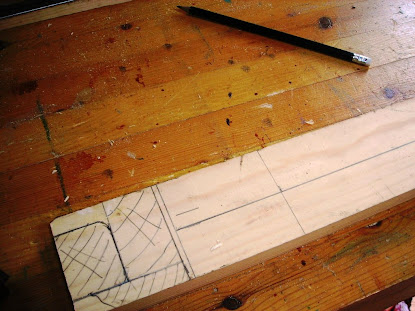

Ideas I think are viable I then try and sketch it out.

Then work out sizes and batter in and make it.

I don't use CAD, scale drawings, or full size rods.

Don't know if I'm taking shortcuts but it works for me.

How do you guys do it?

Ideas I think are viable I then try and sketch it out.

Then work out sizes and batter in and make it.

I don't use CAD, scale drawings, or full size rods.

Don't know if I'm taking shortcuts but it works for me.

How do you guys do it?