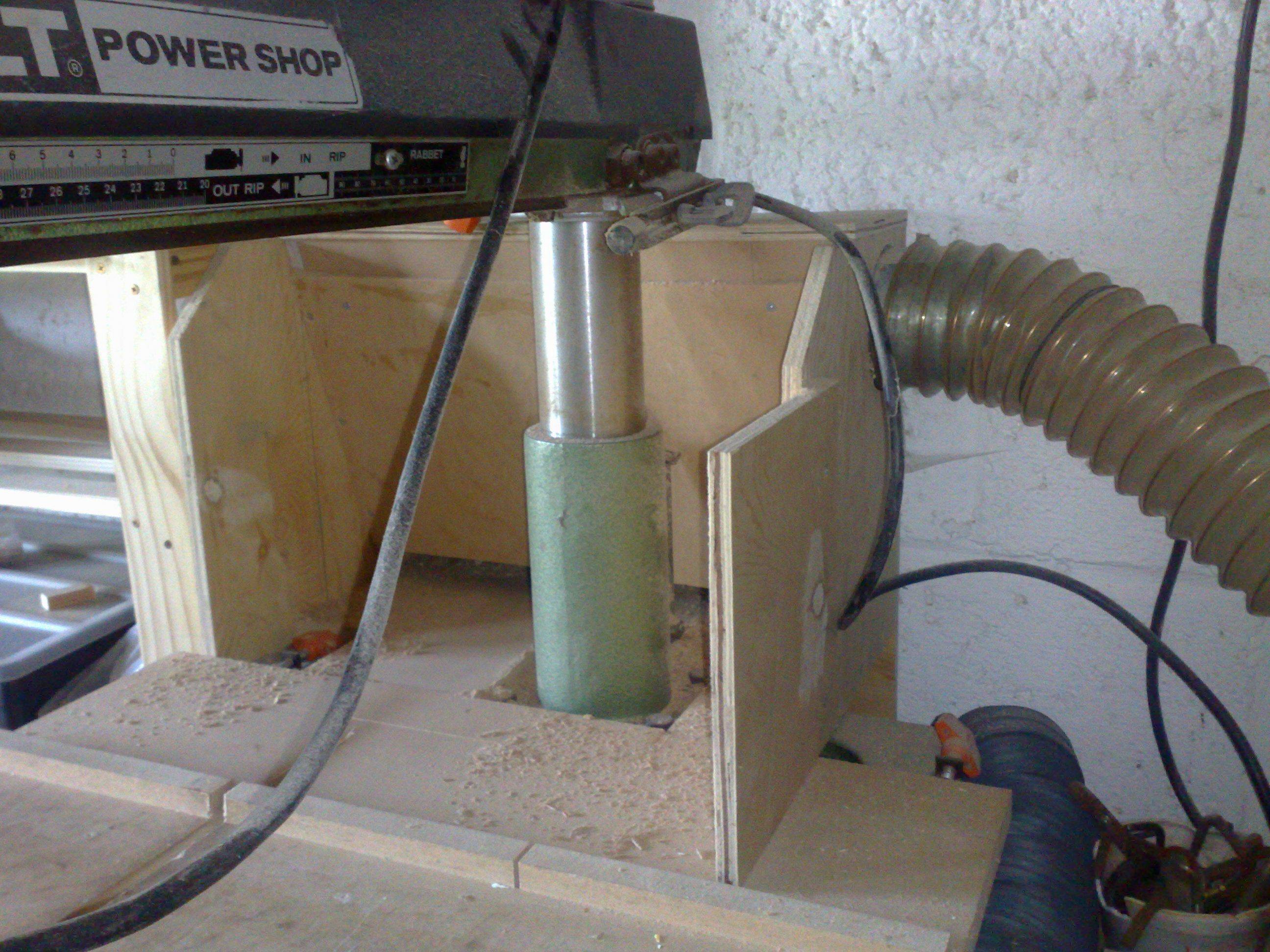

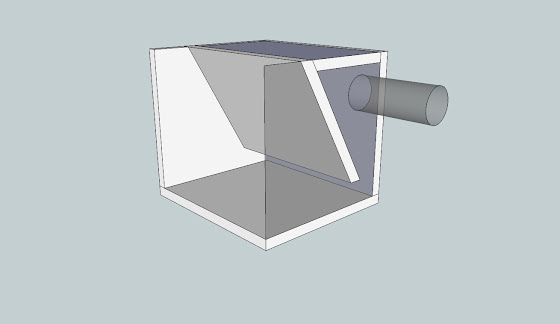

Have any of you built a dust extractor? Ive been looking at the build diary for the dust sniper, it looks very good but I wanted to simplify it and I was wondering if I could just build a big box, line it with some sort of sound proofing material and put the hoover in it.

I would then have a cyclon seperate from this.

My concern is if I can just join two hoovers with a t joint and will this double up on the power? will two 2000watt hoovers equal 4000watts

another question is if its safe to remove the switches from each hoover, extend the wire and mount them to the outside of the box?

If anyone has any experience building a ds id love to hear you story.

Regards

Ben

I would then have a cyclon seperate from this.

My concern is if I can just join two hoovers with a t joint and will this double up on the power? will two 2000watt hoovers equal 4000watts

another question is if its safe to remove the switches from each hoover, extend the wire and mount them to the outside of the box?

If anyone has any experience building a ds id love to hear you story.

Regards

Ben