Lightweeder":5fffqudy said:

I'm still struggling with this. There must be some reason why I'm getting an actual bend in a spindle. It shouldn't be possible!

Starting with the obvious - don't do the tailstock up too hard on long thin work (or work that is going to become thin) - too much pressure from the tailstock can easily (& almost unnoticably until it is too late) distort a long thin thing. You need just enough pressure that the revolving centre revolves with the work and not much more.

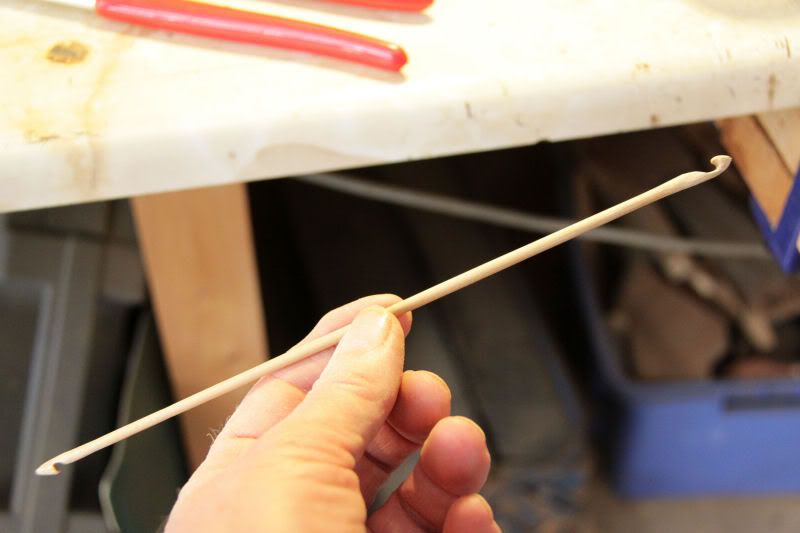

My partner & I make knitting pins, crochet hooks and drop spindles for a local yarn shop and have also have had various problems with long thin things "whipping" and with them not running true after reversing them (where needed). We use home-made wooden collets (as previously descibed) for reversing long thin items when needed and these work well and don't seem to mark the work.

We have had more problems in cold weather (our workshop has very little heating in it) - which we think is caused by either the wood or turner's fingers being too cold (don't laugh!) - so mounted an old bar-shaped greenhouse electric heater under the lathe bed bars.

I use a very small roughing gouge (which I think is intended for pen turning) to make most of my small thin items - if sharp and used gently I find I get on with it better than with a skew and the finish is almost as good. To make the shaped end of a knitting pin or crochet hook I use a 3-point tool (used like a skew, not a like scraper) as I find this is easier to control and seems gentler than a full-sized skew chisel.

Another tip is to make the item all in one go. I have had a perfectly good small crochet hook ruined because a visitor turned up when I had almost finished it and I stopped work to chat to them for about 1/2 an hour. When I returned to the work on the lathe it had slightly bent due to internal stresses in the wood - and was impossible to finish.

Some wood is just difficult - & there can be major differences between pieces cut from the same plank. For long thin items I try to choose the most boring looking, straight grained pieces I can find. Anything with a lot of "figure" will probably whip more because of the internal twistiness of the grain.

Some species of wood are just more "whippy" than others in small section. I use Holly and Damson for small crochet hooks, and can usually get away with sizes down to 5mm with hardly any bother. 4mm & 3mm are trickier to do and require lots of "finger support" from the back while cutting. We use birch for the "stick" part of our drop spindles and find it a reasonable compromise between stiffness and light weight. Walnut & chestnut make nice spindle sticks too.

Hope you find some of the above of use.