adidat

I will not buy anymore tools...

hi

i need some help with a project i working on.

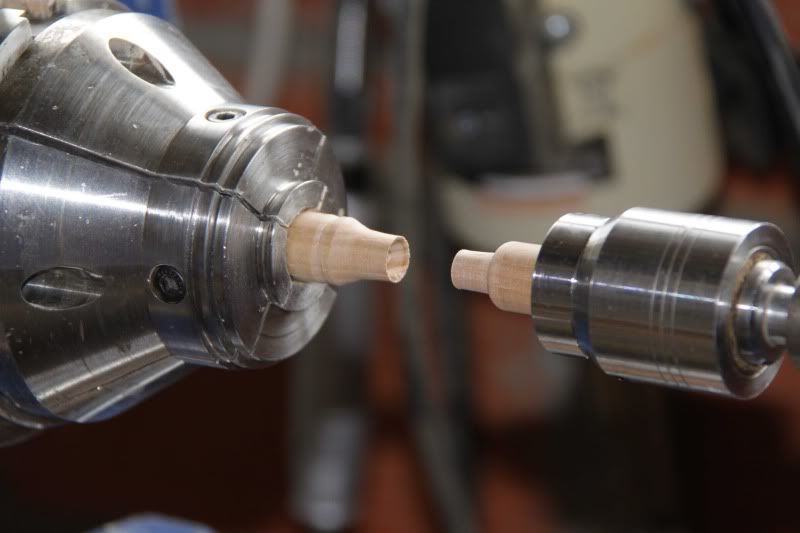

i need to turn these boxwood lengths.

in to balls?

they need to be about 32mm diameter

to finish up with something like this

beer tokens available, apply within

thanks

adidat

i need some help with a project i working on.

i need to turn these boxwood lengths.

in to balls?

they need to be about 32mm diameter

to finish up with something like this

beer tokens available, apply within

thanks

adidat