humanfish

Established Member

Well, i had a tidy up and set up the 2nd hand M950 lathe i got during the week. I took some time to scrape some of the gunk off of the body and i unscrewed the black endcap to the motor fan and the metal around the pullys to give it a spray with air and hoover up any dust i could.

I also had a look and sort out of the bits and bobs that i got with the lathe.

Some tools:

Some faceplates and a few bits i am not entirely sure on just yet. The chuck thing looks like the sort of thing from a drill. I presume it is for putting drill bits in and boring holes.

This is the Multistar Variform screw chuck, there are instructions which i'll have to read through to see what it is designed to be used for.

There is also the Multistar Duplex chuck with 3 different sets of jaws

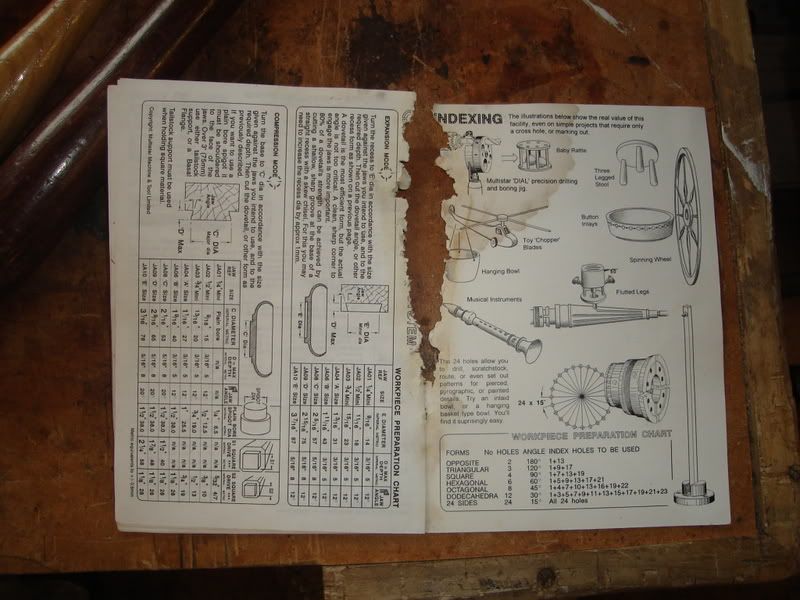

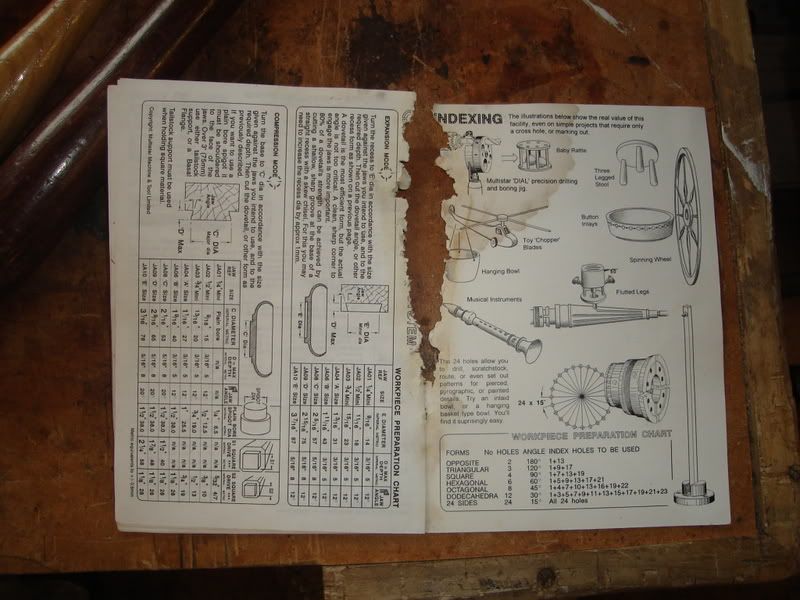

This also has instructions but they have perished in the middle a bit so i might contact Hegner to see if they can send a photocopy of the booklet.

I'll have to have a good read of this as i have never used a chuck, i'll need to figure out what it is used for and in what scenarios. The only turning i have done before was between centres for a pair of hall chairs i made at college a couple of years ago.

So, i have a bit of reading to do before i get to make some shavings. For one i need to have a look through my offcuts for some suitable bits to much through. The main thing i need to do though is understand the processes of using chucks and faceplates and things as previously i have only done the basic between centres stuff.

I have lots of ideas in my head of things i would like to do, nothing to extreme. So i look forward to sharing my attempts in the near future. Should be a cheap christmas this year :lol:

I also had a look and sort out of the bits and bobs that i got with the lathe.

Some tools:

Some faceplates and a few bits i am not entirely sure on just yet. The chuck thing looks like the sort of thing from a drill. I presume it is for putting drill bits in and boring holes.

This is the Multistar Variform screw chuck, there are instructions which i'll have to read through to see what it is designed to be used for.

There is also the Multistar Duplex chuck with 3 different sets of jaws

This also has instructions but they have perished in the middle a bit so i might contact Hegner to see if they can send a photocopy of the booklet.

I'll have to have a good read of this as i have never used a chuck, i'll need to figure out what it is used for and in what scenarios. The only turning i have done before was between centres for a pair of hall chairs i made at college a couple of years ago.

So, i have a bit of reading to do before i get to make some shavings. For one i need to have a look through my offcuts for some suitable bits to much through. The main thing i need to do though is understand the processes of using chucks and faceplates and things as previously i have only done the basic between centres stuff.

I have lots of ideas in my head of things i would like to do, nothing to extreme. So i look forward to sharing my attempts in the near future. Should be a cheap christmas this year :lol: