Rhyolith

Established Member

Guys could take the discussion about torque to its own thread please.

Thanks

Thanks

Done: advantage-of-longer-screwdrivers-more-leverage-or-t99646.htmlRhyolith":pnk6sjex said:Guys could take the discussion about torque to its own thread please.

You could deliberately cause it to flash-rust, then stabilise the rust. This in essence recreates 'patina' on steel.Rhyolith":83h6wom4 said:You mean let it oxidise a bit? Probably not since it would take a while and I don't like thr idea of corroding it.

Yorkshire Sam":3p0auk5q said:These engineers screwdrivers are quite common. A typical use would be for unscrewing deck plates in machinery spaces ie ships. The reason for the length is to save bending too much and the flat so that a spanner could apply any extra torque needed for stuck screws which were usually quite large diameter ( although short in length) with flat heads chamfered heads to keep the machine plates flat.

Even 'new; they were seldom shiny.

Giant Screwdriver by Rhyolith, on Flickr

Giant Screwdriver by Rhyolith, on Flickr Giant Screwdriver by Rhyolith, on Flickr

Giant Screwdriver by Rhyolith, on Flickr Giant Screwdriver & Large Yankee by Rhyolith, on Flickr

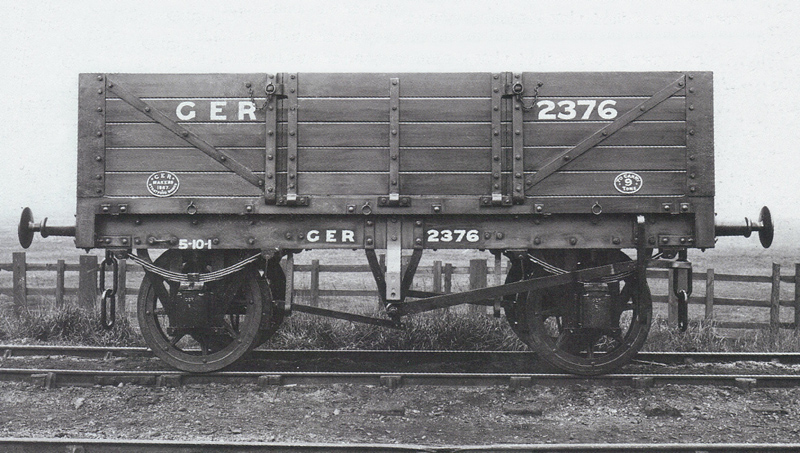

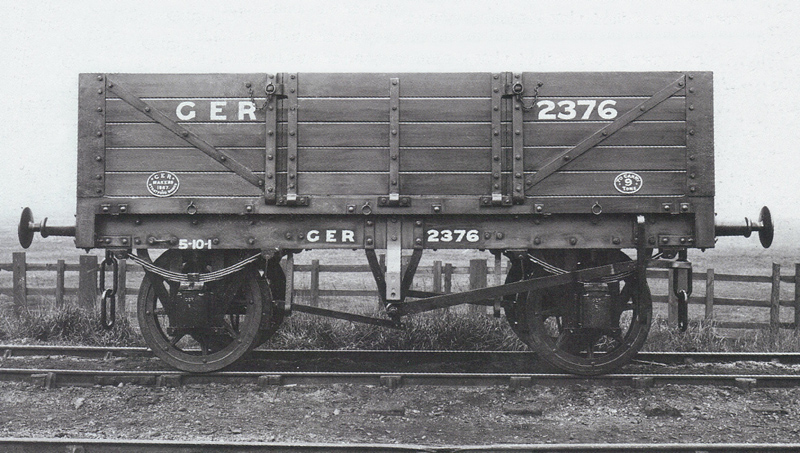

Giant Screwdriver & Large Yankee by Rhyolith, on FlickrOops just got to revise that! I've dug out a box of Nettlefold screws size 20 x 1 1/4". I knew they were there I'd forgotten how big they were!Jacob":8qnu6qup said:Yes and there was a whole technology of wood plus metal which has more or less disappeared. Boats, ships, railway wagons, silos, industrial plant, farm machinery, often made with timber and metal plates with large (but short) screws as well as longer coach screws (with square heads) ,rivets, bolts etc.

There is a size limit on slotted screws - 14 perhaps, above which you'd need the leverage of a spanner on a nut

morturn":2m4dylf4 said:Of course as with all us woodworkers, they would line up all of the slots to face the same direction. Only in this case it means taking the screw out and giving the countersink tool a few extra turns just to get things to line up.

bugbear":3peep1a4 said:The upper section of the blade looks as if it's intended to be a handle - or at least it's shaped for it.

But that makes no sense.

Am I over interpreting a decorative shape?

BugBear

Enter your email address to join: