Ta for the explanation regarding the gears. Perhaps I'm just being a numpty but I don't understand how adding gears could alter the speed the waterwheel spins at ?

Say I've got a pond pump that can move 10000litres an hour- that's fixed, I can't alter the flow. I've also got a wheel with certain size buckets and a certain weight, I can't easily alter that. If those 2 things cause the waterwheel to spin too fast, adding cogs/gears would only control something I was using the waterwheel to drive ? I don't need this to drive anything, I just want the wheel to turn and to make a splashy sound.

While looking for waterwheel pictures last night, I stumbled across a handy website. This guy sells bit to make your own waterwheel. One of the things he sells, is a brake to slow waterwheels down.

Looks like a fairly straightforward way to add friction if required.

Been coughing like a champ since using this awful iroko again.

Even wearing a mask, with air filter running, my lungs feel like I'm smoking 20 cigs a day. So glad I stopped using this and switched to sapele/utile for most jobs.

I did a test fit with the metal rings. As you can see they really are an awful shape

One of them went on relatively easy, the other I think I could get on, but don't think it'd come off again so I'll leave that until it's ready to stay on permanently. I need to flush trim the outside of the wheel to the newly router diameter. I'm hesitant to use a router cutter cause iroko being so abrasive just kills them. I might use the spindle moulder and a rebate block instead if I can manage the awkward size.

I hot glued the wheel to my bench to do the routing, it's safe to say the hot glue did it's job, almost too good. I've ripped the ply bench top in a few places trying to remove it.

The worry thing is the waterwheels getting smaller the more I work on it.

The mdf fins are the maximum size I could get from my iroko dog ends. I like how it might look, just hope I'll have enough flow for it to turn.

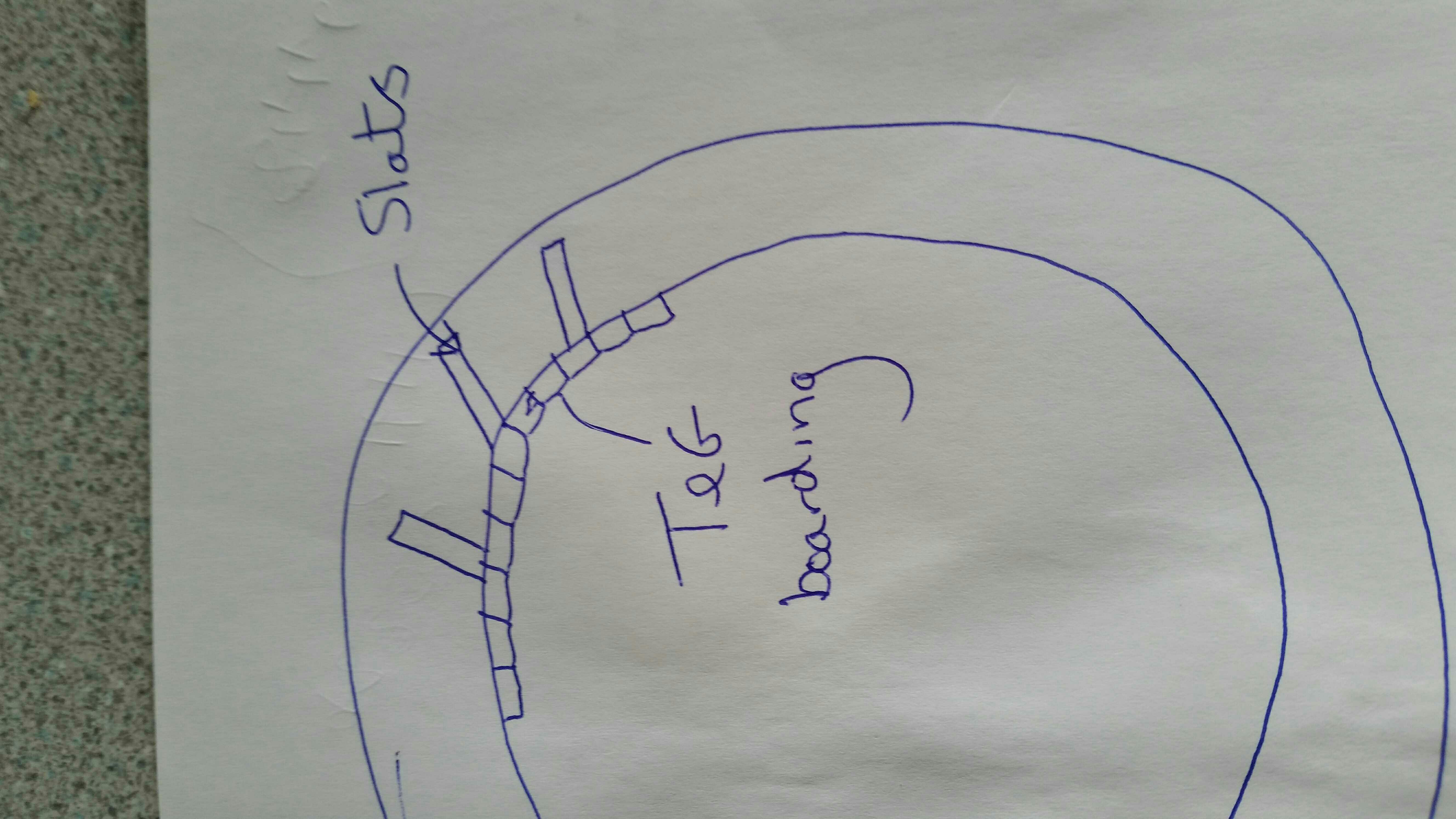

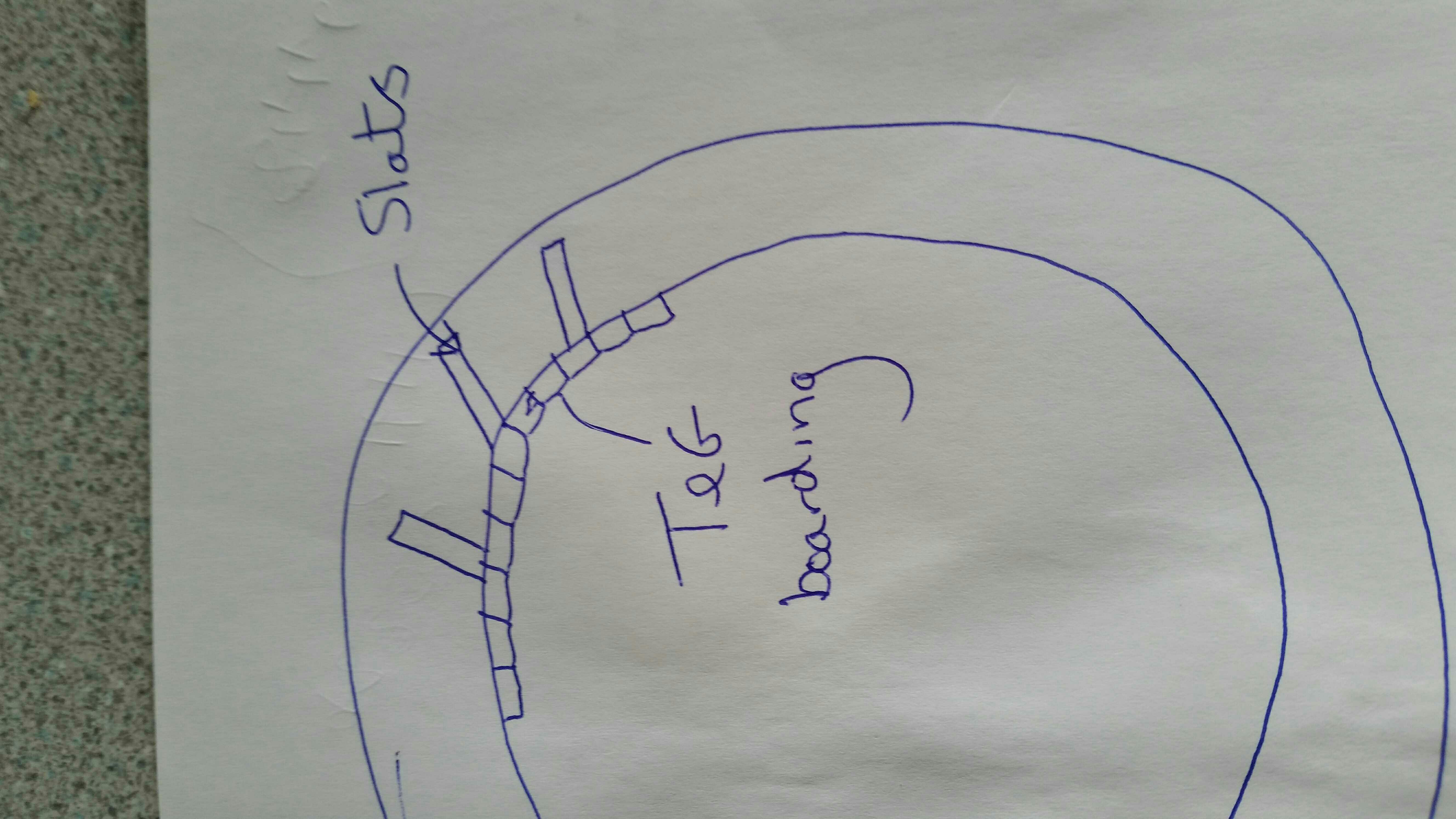

Mike, does the bucket position seem about right regarding the 4.30 position ? I've put my foot where I think it looks like it should start emptying.

Cheers guys

Coley

Sent from my SM-G900F using Tapatalk