mikefab

Established Member

Here are some photos of some fitted furniture I made for my neighbours. It's the first time I've done work for somebody else so it was an interesting experience taking their ideas, building on them / moderating them and turning them into a design for approval.

Timber Ready for face frames

Ripping down some oak for the worktop.

Stickered in the house for a bit

Face frame glued up (sycamore, was very cheap as some mould stains)

Carcasses in production on the driveway

Face frame test fitted to carcasses in my front hall to allow door fitting.

Solid oak drawer boxes made from local 3/4" northumberland oak (offcuts friends at local joinery firm). Bases from 6mm oak veneered mdf. Drawer sides joined with groove/rebate and PU adhesive. Man the squeeze out was a pain... finished with osmo Poly X.

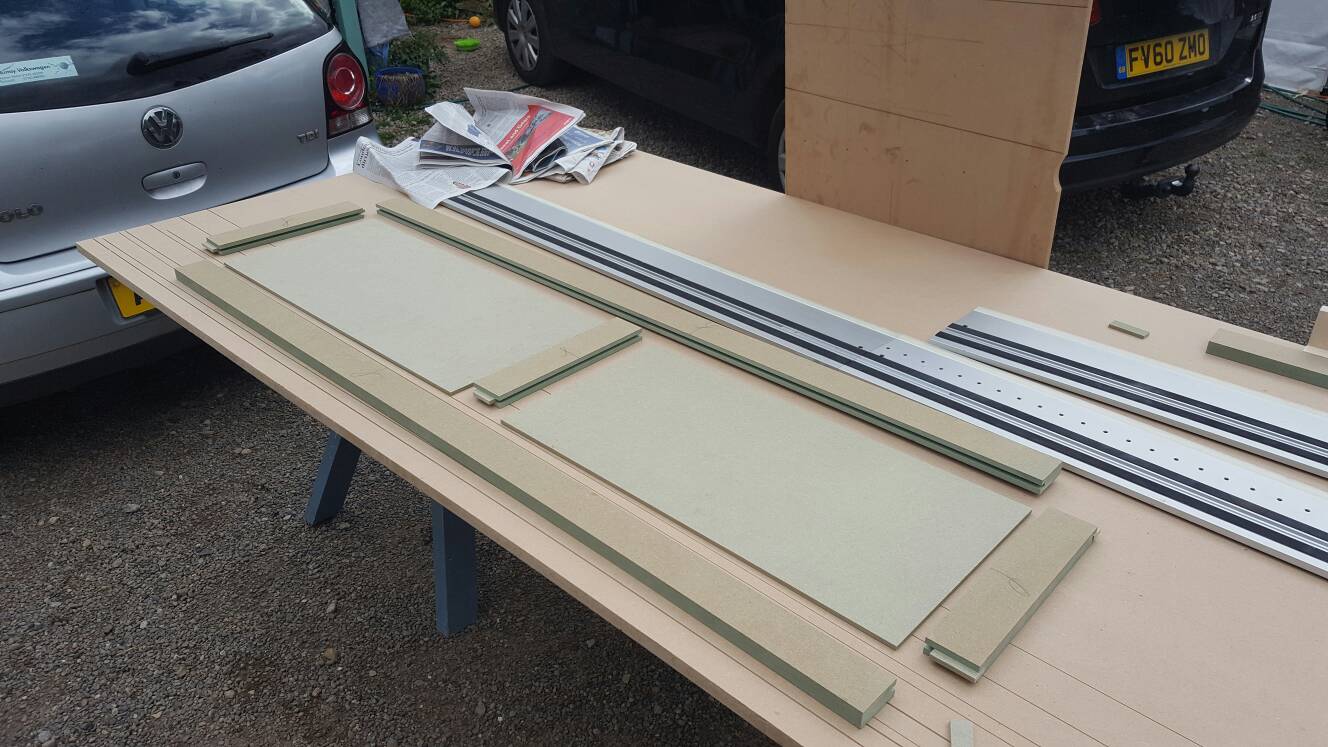

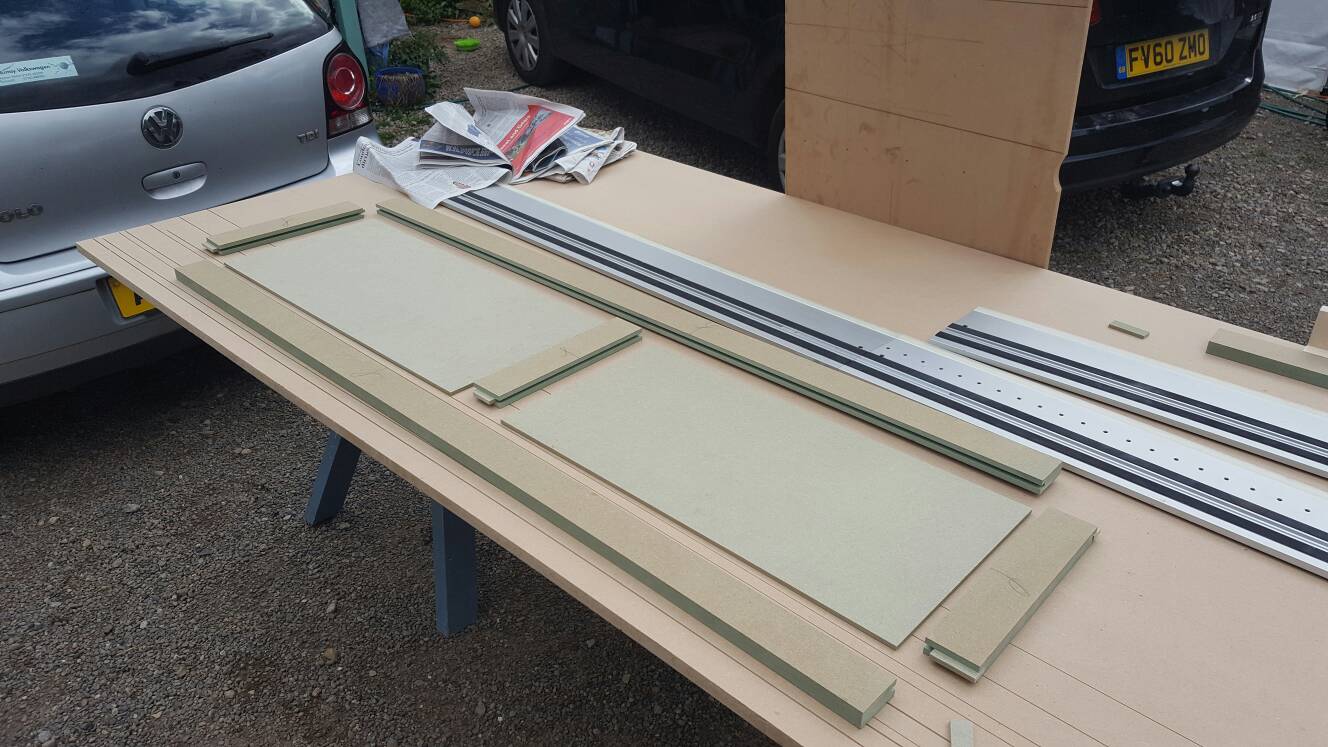

Doors glued up from 22mm MR MDF

I didn't take any pics during the install apart from this!

Finished project, all components hand painted prior to install to minimise time and mess on site.

There was a little touching up of filled nail holes in the skirting after these photos but that's it.

Runners were blum tandem soft close, hinges blum clip top blumotion. Paint was Dulux trade eggshell (oil based by mistake!). Carcasses were Egger MFC (very heavy!!).

Thanks for looking!

Mike

Timber Ready for face frames

Ripping down some oak for the worktop.

Stickered in the house for a bit

Face frame glued up (sycamore, was very cheap as some mould stains)

Carcasses in production on the driveway

Face frame test fitted to carcasses in my front hall to allow door fitting.

Solid oak drawer boxes made from local 3/4" northumberland oak (offcuts friends at local joinery firm). Bases from 6mm oak veneered mdf. Drawer sides joined with groove/rebate and PU adhesive. Man the squeeze out was a pain... finished with osmo Poly X.

Doors glued up from 22mm MR MDF

I didn't take any pics during the install apart from this!

Finished project, all components hand painted prior to install to minimise time and mess on site.

There was a little touching up of filled nail holes in the skirting after these photos but that's it.

Runners were blum tandem soft close, hinges blum clip top blumotion. Paint was Dulux trade eggshell (oil based by mistake!). Carcasses were Egger MFC (very heavy!!).

Thanks for looking!

Mike

Last edited by a moderator: