Jacob

New Luddism. Awake and resist!

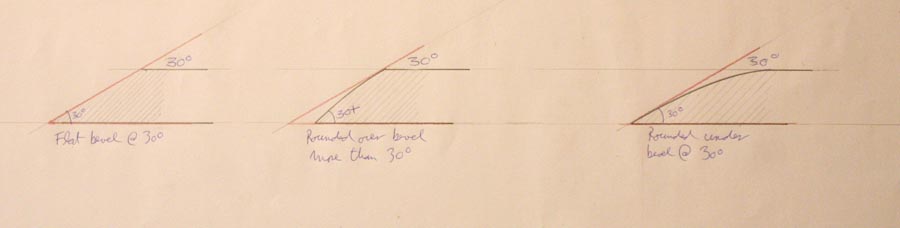

Yes , since a rounded under sharp edge will cut perfectly well.dunbarhamlin":2lwwo2m6 said:To my eye, this looks like the author had rounding over in mind, since the only (sharp) edge which cannot cut well would be one which was too obtuse for the application.1934":2lwwo2m6 said:...as this must inevitably result in a curved edge that cannot cut well...

BB & co seem to think that I am the first person in the universe to discover this, which is flattering