Mikelewis

Member

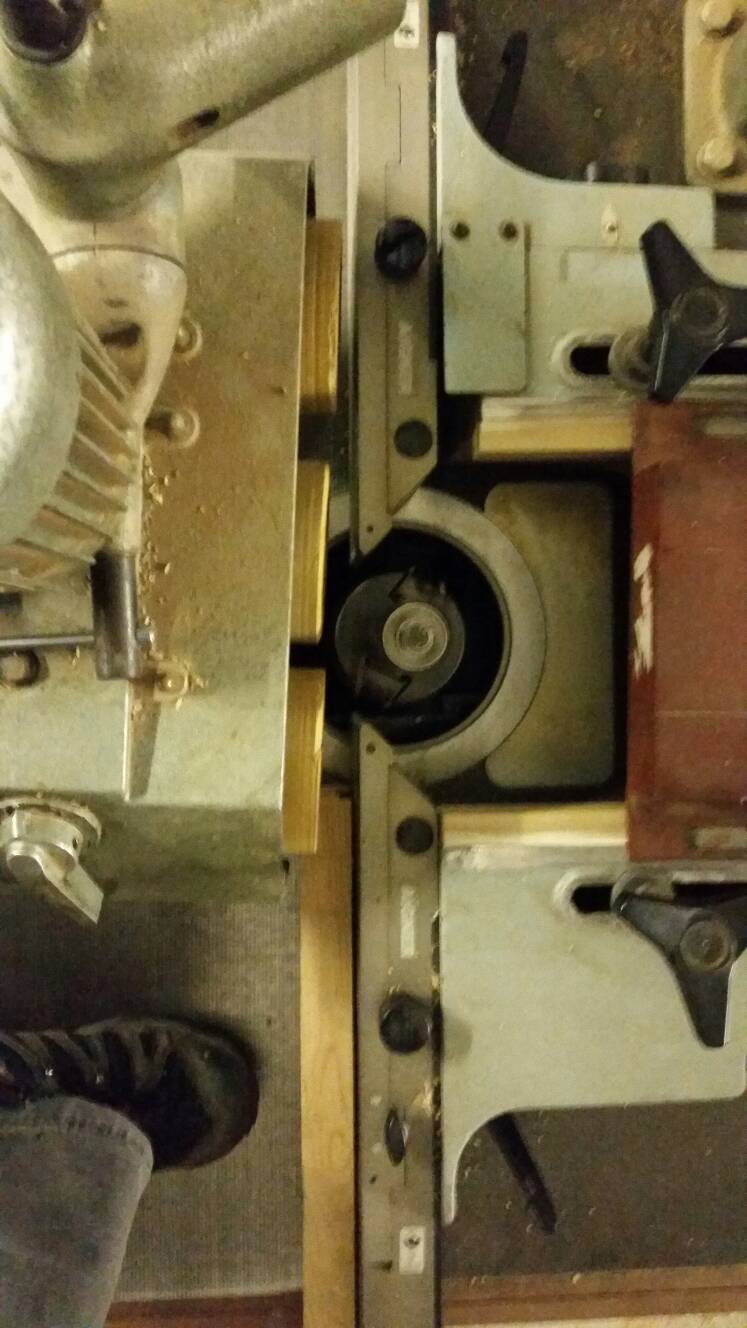

I am currently making my own windows using the trend modular system, and I'm having a nightmare with the power feeder. I have read all the instruction, watched all the videos on YouTube tried so may variations that I have lost count.

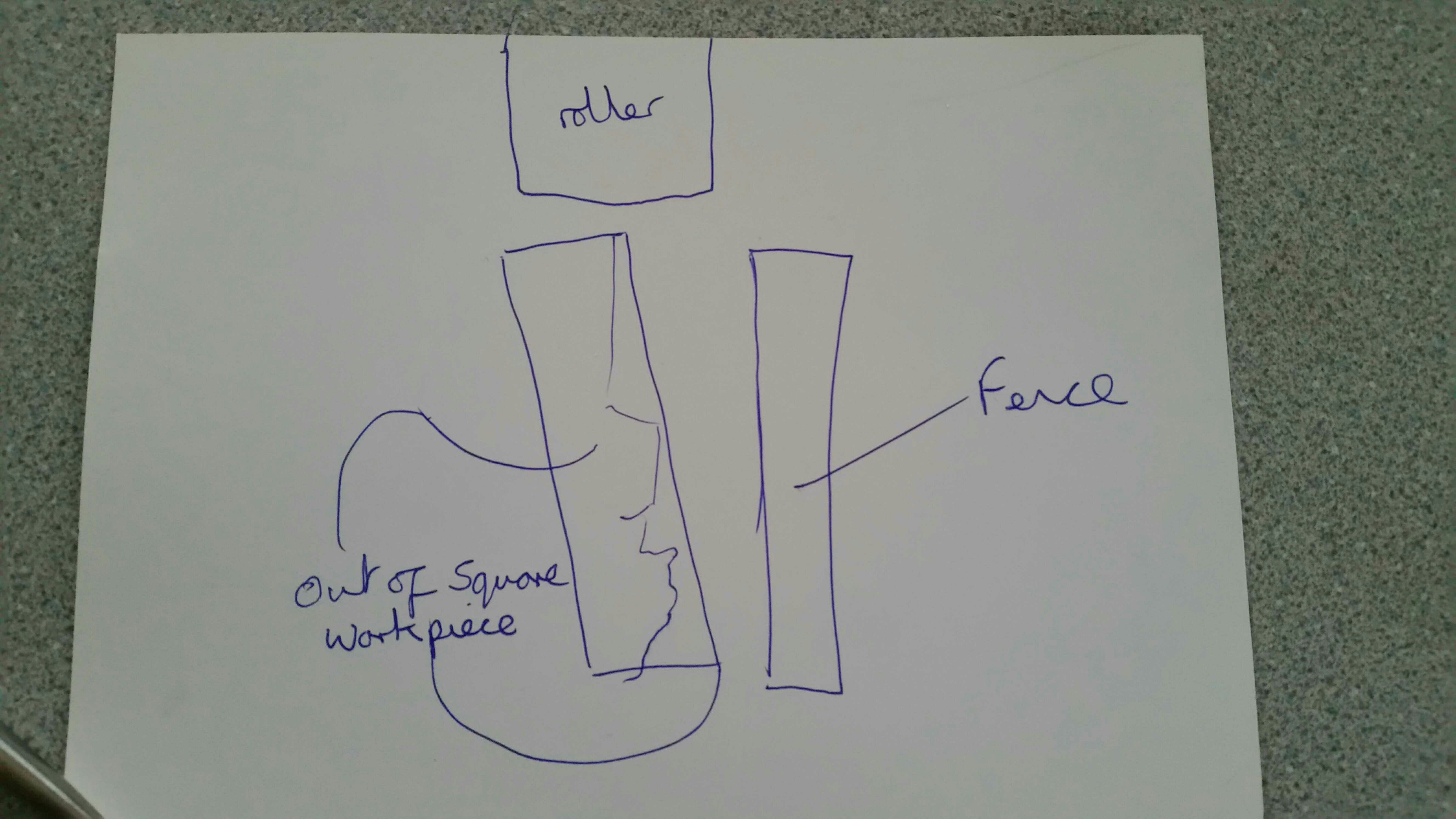

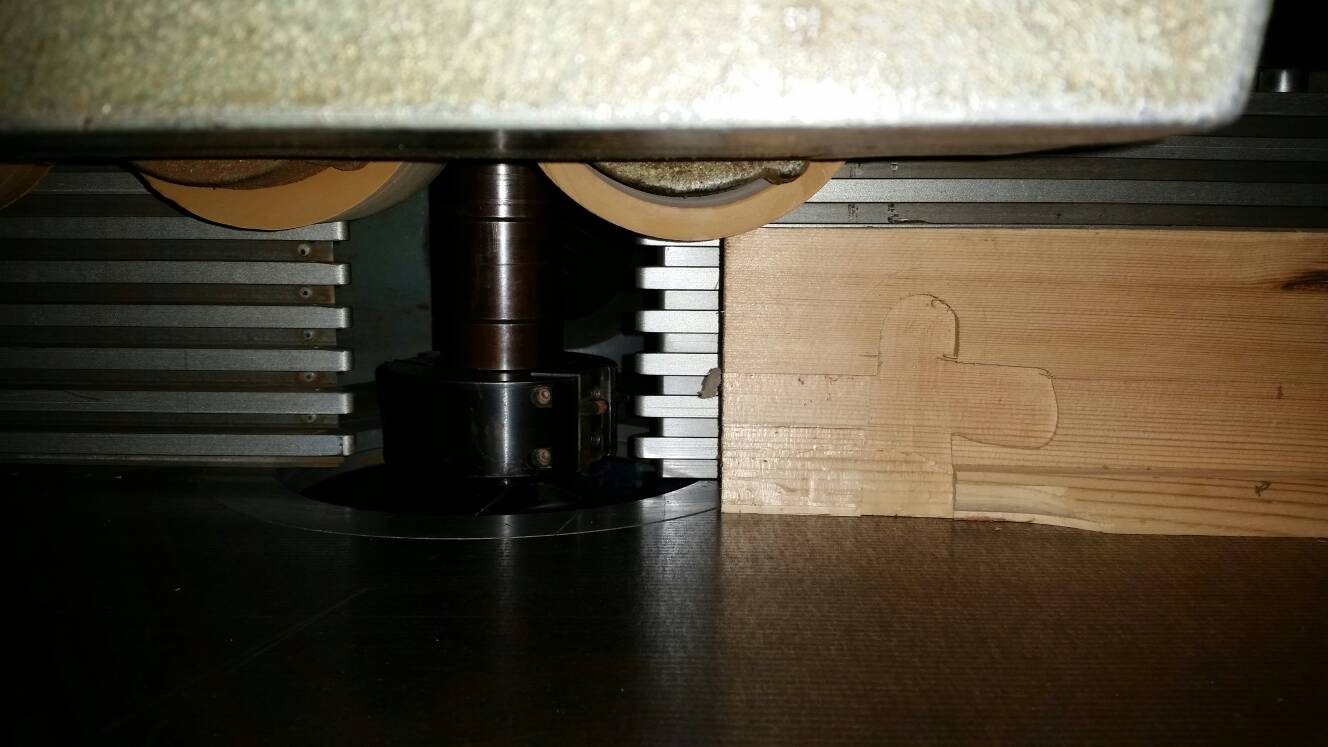

I am having two problems when I feed the stock through which is engineered oak blanks, the wood is pushed out, mainly at the end of the stock, and secondly with a different set of tools the wood is cut deeper at the end. It seems that the wood is being pushed into the cutter at the end. I have fitted MDF fences for each of the tooling set ups as advised but the problems are still there.

The other question is how to you contact a user, whydi posted a useful reply on the same topic and would like to contact him.

If anyone is interested I can post a video on YouTube showing the exact problems.

Thanks

I am having two problems when I feed the stock through which is engineered oak blanks, the wood is pushed out, mainly at the end of the stock, and secondly with a different set of tools the wood is cut deeper at the end. It seems that the wood is being pushed into the cutter at the end. I have fitted MDF fences for each of the tooling set ups as advised but the problems are still there.

The other question is how to you contact a user, whydi posted a useful reply on the same topic and would like to contact him.

If anyone is interested I can post a video on YouTube showing the exact problems.

Thanks