devonwoody

Established Member

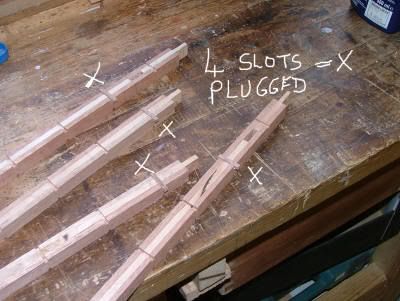

I eventually got out to the workshop at around 13.30 hours and the temp reached 10c with the help of a fan heater. Did a bit more jointing but wanted to do something more active, I therefore set up the table saw and cut all the dadoes dead centre 5 mm deep in all drawers. Used a back up on the second cut each time and avoided any tearout. Decided not to cut the positions on the frames today because I want a very accurate layout after my first box 6 months ago. I am going to make a cut on a frame and then put in a drawer to act as spacer and build up the positions in this fashion. Hoping this will avoid mark up errors. Even now I am still concerned about this step, wondering if I should build a sled to push timber past the unguarded blade. There will only be around 75mm between hand and blade.

Photograph of four drawers showing slide bars sitting snugly without any play.

Photograph of four drawers showing slide bars sitting snugly without any play.