Stimpi

Established Member

Just a few tips for concreting.

1 Generally for each meter of concrete you should have one person eg. 6m cube 6 able bodies. Or if you only have 2 bodies to help order 2 m3

2 The initial set starts as soon as the water is added this gives about 25 minutes to half an hour to curing starting. This is why a clerk of works will condem a load if its been standing after water is added which is why drum wagons are preferred. 0.05% of the water starts the chemical setting process the rest is for workability. If the concrete does not get laid quick enough it becomes less workable. Adding water at this point weakens the concrete

3 Strength of supports (formwork) is dependent on rate of pour eg. Pouring 600 square column 3 metre high will take more pressure than a same height wall 5m long.

4 A six inch slab a tamp width wide (7feet) will need a peg at 2’0” centres

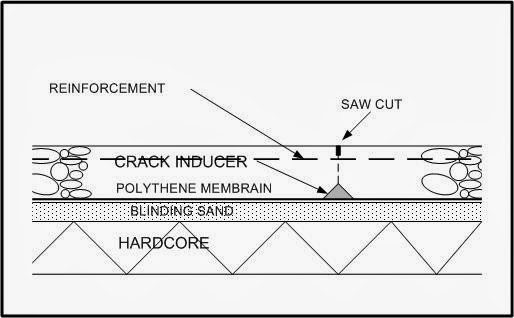

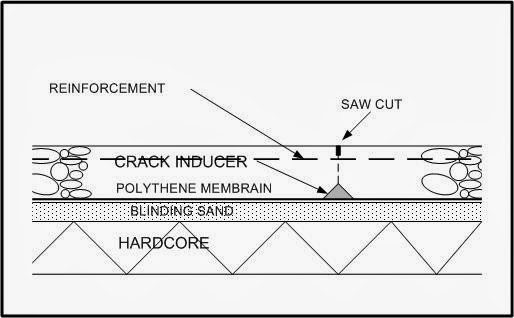

5 Any slab less than 4” will crack no matter what you put in it. Its expansion and contraction that causes concrete to crack. It contracts and expands at the same rate as mild steel which is why mild steel is used for reinforcement.

6 Polythene sheet as well as a damp membrane allows the concrete to slide and stops loss of water before setting.

7 Set some crack inducers about every 5m if is a lengthy pour mark where you placed them on the edge shutter and then cut with an angle grinder next day. A crack inducer (a Scheigal) is a triangular piece of wood or plastic say 1” sides.

8 Get your team together a decent time ahead of the concrete arriving with clean shovels (polished may be asking too much) brief them on how you are tackling the job eg. Starting at the furthest point of entry keeping access clear.

Best of luck.

1 Generally for each meter of concrete you should have one person eg. 6m cube 6 able bodies. Or if you only have 2 bodies to help order 2 m3

2 The initial set starts as soon as the water is added this gives about 25 minutes to half an hour to curing starting. This is why a clerk of works will condem a load if its been standing after water is added which is why drum wagons are preferred. 0.05% of the water starts the chemical setting process the rest is for workability. If the concrete does not get laid quick enough it becomes less workable. Adding water at this point weakens the concrete

3 Strength of supports (formwork) is dependent on rate of pour eg. Pouring 600 square column 3 metre high will take more pressure than a same height wall 5m long.

4 A six inch slab a tamp width wide (7feet) will need a peg at 2’0” centres

5 Any slab less than 4” will crack no matter what you put in it. Its expansion and contraction that causes concrete to crack. It contracts and expands at the same rate as mild steel which is why mild steel is used for reinforcement.

6 Polythene sheet as well as a damp membrane allows the concrete to slide and stops loss of water before setting.

7 Set some crack inducers about every 5m if is a lengthy pour mark where you placed them on the edge shutter and then cut with an angle grinder next day. A crack inducer (a Scheigal) is a triangular piece of wood or plastic say 1” sides.

8 Get your team together a decent time ahead of the concrete arriving with clean shovels (polished may be asking too much) brief them on how you are tackling the job eg. Starting at the furthest point of entry keeping access clear.

Best of luck.