memzey

Established Member

Hi gang,

As promised here is my retrospective wip on the steps I took to make SWMBO a coffee table for the front room (as mentioned in a couple of previous posts where I have asked for help/opinion at various times). Not sure what the limit on photos per post is on this new software so I will limit each post to 5 or 6 to stay on the safe side.

As a starting point I quite liked the general design of a table that Paul Sellers did a series on (https://woodworkingmasterclasses.com/ca ... ffeetable/) but there were a few things I did not like:

Firstly I thought there was a bit too much in the way of end grain visible on the top for my taste. I myself prefer either making a feature of end grain or hiding it as much as possible - but that is just my personal preference and not in any way a statement of what "good" is (I'll be the first to say that I'm the least qualified person to comment on such a thing).

Secondly I wasn't overly enamoured with the curved aprons of the original. Again a matter of taste but I thought it looked a bit 1972 for my liking (and more importantly so did SWMBO).

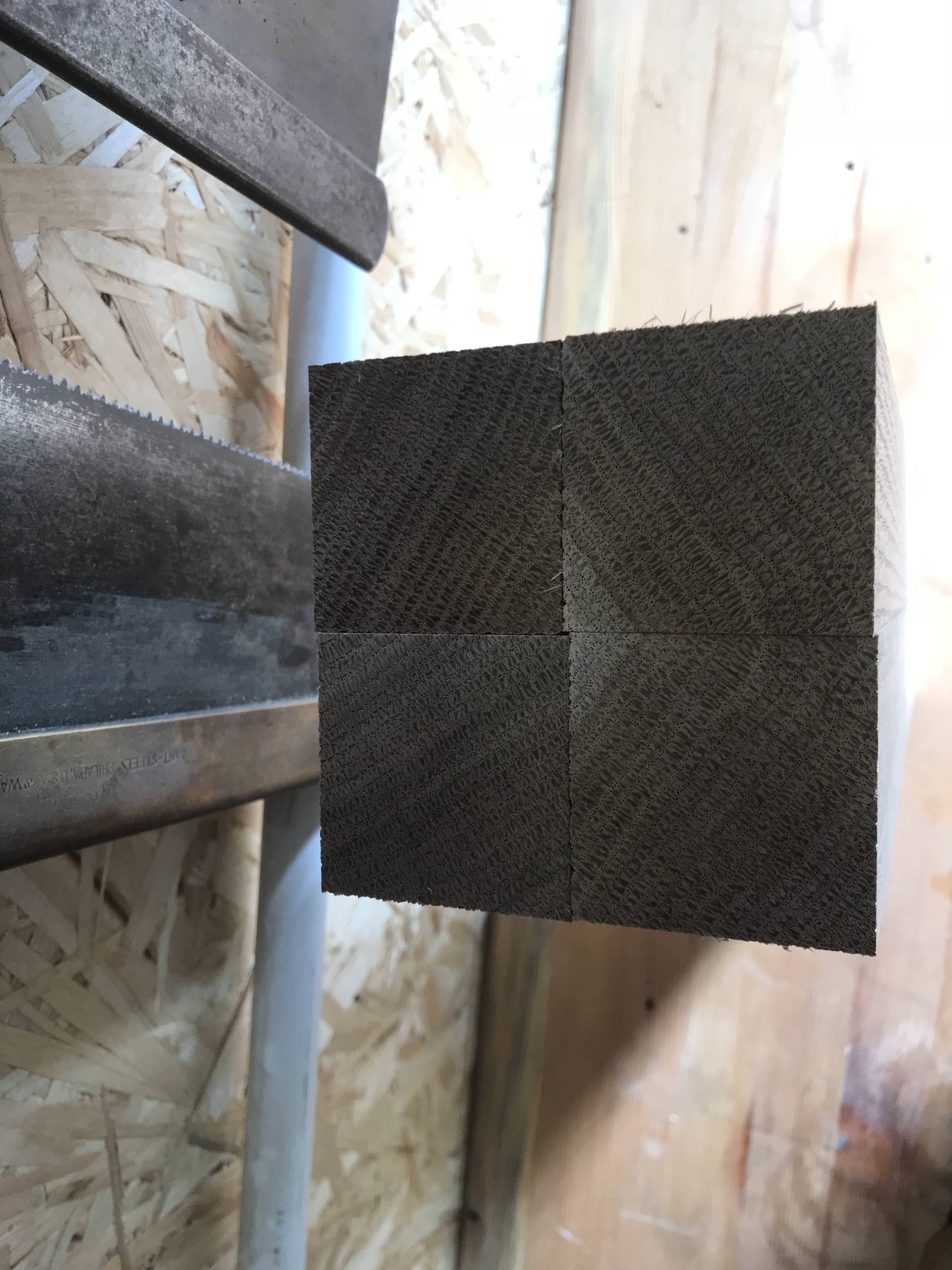

Thirdly I thought the tusk through tenons were nice but could be improved upon as a "look at me - I'm not from OFL" feature for this piece of furniture.

Finally I wanted to use contrasting woods for aesthetic effect where possible rather than just stick to oak.

So while my design is in no way original, I did adapt an existing proven design to suit the particular needs and tastes of my household (at this point I should really show a sketch I did of what I was aiming for but I'm on a train from Edinburgh to London and I previously neglected to photo the design (homer))

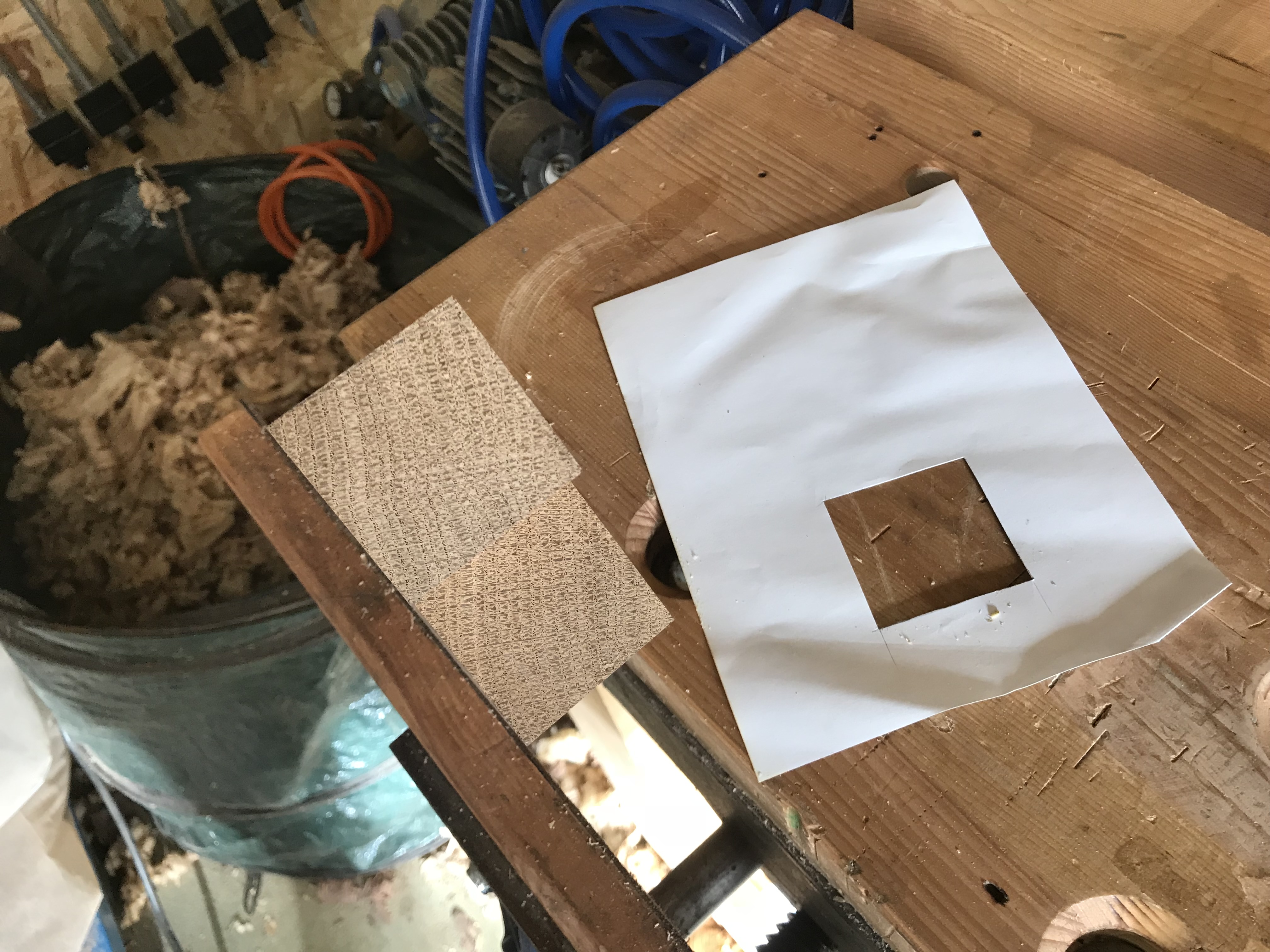

Anyway on to stuff - I started with 1" rough sawn boards of Oak for the top and American Black Walnut (ABW) for the shelf. I rough cut, planed and thicknessed these down to size by hand* and then placed in stick for a while before final dimensioning:

*"By hand" = I manually, with my own bare hands and no mechanical assistance whatsoever, put the boards through my table saw and planer thicknesser :wink:. I did prepare the edges for final jointing with bench planes though, as I find doing so leaves a far less visible glue line.

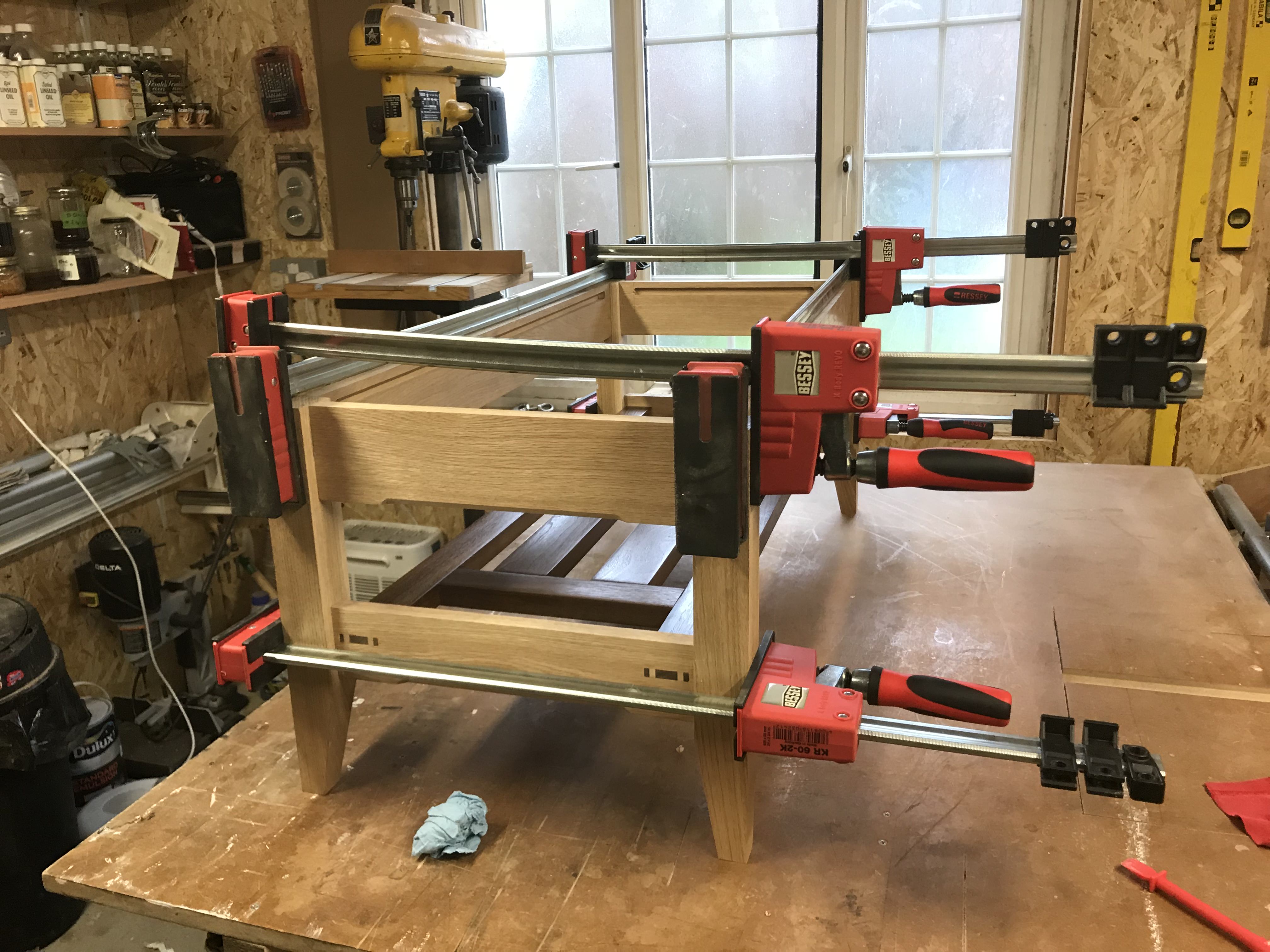

I used four boards for the top and initially glued these up in to two pairs before joining those. I had a bit of a problem with some warping between final dimensioning and glue up (I opened a thread on this back in October I think) but got round it with the use of bearers, cauls and plenty of cramps during the glue up:

Once out of the cramps the top was mercifully flat(ish). I started preparing it by first scraping off the squeeze out:

Then flattening and smoothing the face only with a panel plane and 4 1/2:

The edge joints themselves actually came out nice and tight and not particularly obvious, even with a fairly close look:

Lovely (especially considering the fact it was me making the joints).

The next step to hope for the best for was the undercarriage.

As promised here is my retrospective wip on the steps I took to make SWMBO a coffee table for the front room (as mentioned in a couple of previous posts where I have asked for help/opinion at various times). Not sure what the limit on photos per post is on this new software so I will limit each post to 5 or 6 to stay on the safe side.

As a starting point I quite liked the general design of a table that Paul Sellers did a series on (https://woodworkingmasterclasses.com/ca ... ffeetable/) but there were a few things I did not like:

Firstly I thought there was a bit too much in the way of end grain visible on the top for my taste. I myself prefer either making a feature of end grain or hiding it as much as possible - but that is just my personal preference and not in any way a statement of what "good" is (I'll be the first to say that I'm the least qualified person to comment on such a thing).

Secondly I wasn't overly enamoured with the curved aprons of the original. Again a matter of taste but I thought it looked a bit 1972 for my liking (and more importantly so did SWMBO).

Thirdly I thought the tusk through tenons were nice but could be improved upon as a "look at me - I'm not from OFL" feature for this piece of furniture.

Finally I wanted to use contrasting woods for aesthetic effect where possible rather than just stick to oak.

So while my design is in no way original, I did adapt an existing proven design to suit the particular needs and tastes of my household (at this point I should really show a sketch I did of what I was aiming for but I'm on a train from Edinburgh to London and I previously neglected to photo the design (homer))

Anyway on to stuff - I started with 1" rough sawn boards of Oak for the top and American Black Walnut (ABW) for the shelf. I rough cut, planed and thicknessed these down to size by hand* and then placed in stick for a while before final dimensioning:

*"By hand" = I manually, with my own bare hands and no mechanical assistance whatsoever, put the boards through my table saw and planer thicknesser :wink:. I did prepare the edges for final jointing with bench planes though, as I find doing so leaves a far less visible glue line.

I used four boards for the top and initially glued these up in to two pairs before joining those. I had a bit of a problem with some warping between final dimensioning and glue up (I opened a thread on this back in October I think) but got round it with the use of bearers, cauls and plenty of cramps during the glue up:

Once out of the cramps the top was mercifully flat(ish). I started preparing it by first scraping off the squeeze out:

Then flattening and smoothing the face only with a panel plane and 4 1/2:

The edge joints themselves actually came out nice and tight and not particularly obvious, even with a fairly close look:

Lovely (especially considering the fact it was me making the joints).

The next step to hope for the best for was the undercarriage.