MarkDennehy

Established Member

Hi folks,

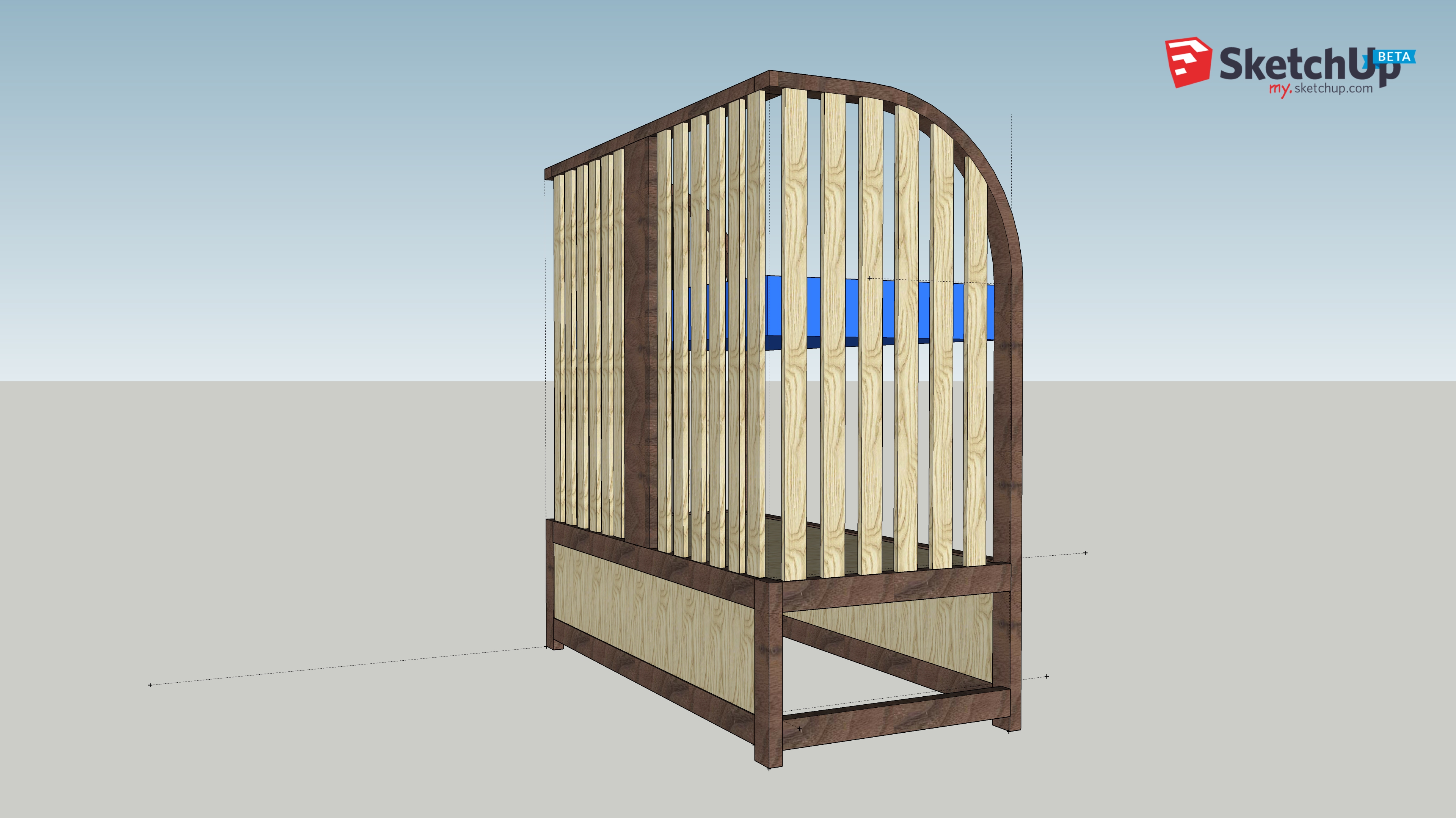

So I've been working away on a small project for the last little while, and finally managed to get some steambending done (it's not perfect but it might do, if I can just blind the person who's getting the project at the end). But part of the design basically requires mortices to be cut into the inside of the curve of the steambent bits (not many, two or three with a few inches of spacing between them) with the mortice running along the curve instead of across it:

(I know the edges of the bent bit look like they're not very sharp, that's an optical illusion caused by the edges not being very sharp. The compression strap slipped, there were surface cracks, there was spokeshave work and that's not complete yet, but the inner surface has no major defects, it just needs a little smoothing over with the spokeshave)

So... anyone got any good tips on cheating at cutting mortices into inside corners by hand?

So I've been working away on a small project for the last little while, and finally managed to get some steambending done (it's not perfect but it might do, if I can just blind the person who's getting the project at the end). But part of the design basically requires mortices to be cut into the inside of the curve of the steambent bits (not many, two or three with a few inches of spacing between them) with the mortice running along the curve instead of across it:

(I know the edges of the bent bit look like they're not very sharp, that's an optical illusion caused by the edges not being very sharp. The compression strap slipped, there were surface cracks, there was spokeshave work and that's not complete yet, but the inner surface has no major defects, it just needs a little smoothing over with the spokeshave)

So... anyone got any good tips on cheating at cutting mortices into inside corners by hand?