Bluekingfisher

Established Member

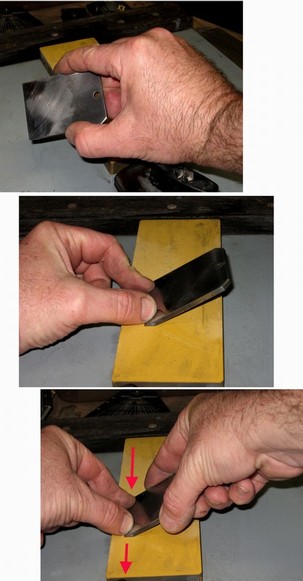

while perusing the Tube last evening I ended up watching several vidoes by accomplished woodworkers on 'how to sharpen a chisel'

What was apparent was most sharpened free hand ( not surprising) however, several of them sharpened the chisel only on the primary bevel i.e no micro or secondary bevel created.

Are there advantages/disadvantages to this. The main advantage I suspect is not having to regrind as the primary as it will remain constant.

Anything else I am missing? and does anyone else sharpen this way?

David

What was apparent was most sharpened free hand ( not surprising) however, several of them sharpened the chisel only on the primary bevel i.e no micro or secondary bevel created.

Are there advantages/disadvantages to this. The main advantage I suspect is not having to regrind as the primary as it will remain constant.

Anything else I am missing? and does anyone else sharpen this way?

David