Allubo

Established Member

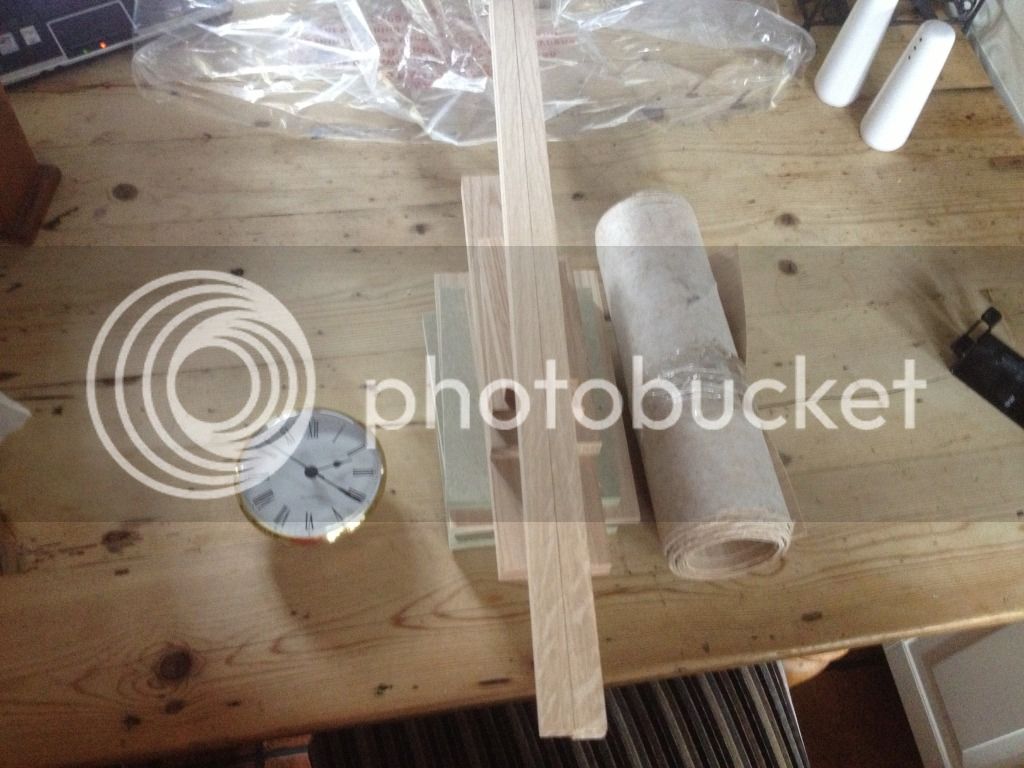

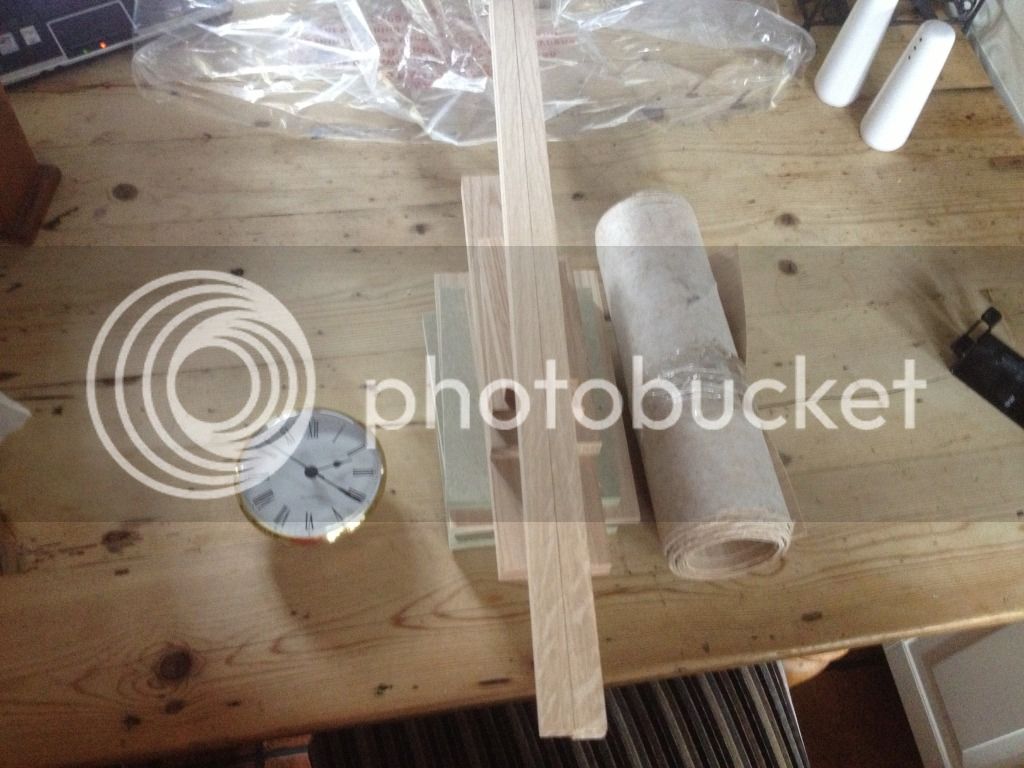

Back in march I made a carriage clock commissioned by a family friend for his granddaughter wedding, he had one made for his daughters and wanted the same thing for her. Although not really my thing, I did enjoy making it and it helped the guy out at short notice.

The piece was made mainly from solid oak with a veneered front, I basically looked at his daughter version and copied it's methods with a few adaptations, mainly thicker material and a sliding back panel rather than those nasty spinning things you get on the back of picture frames.

I started by cutting the front panel and side panels and assembling from there.

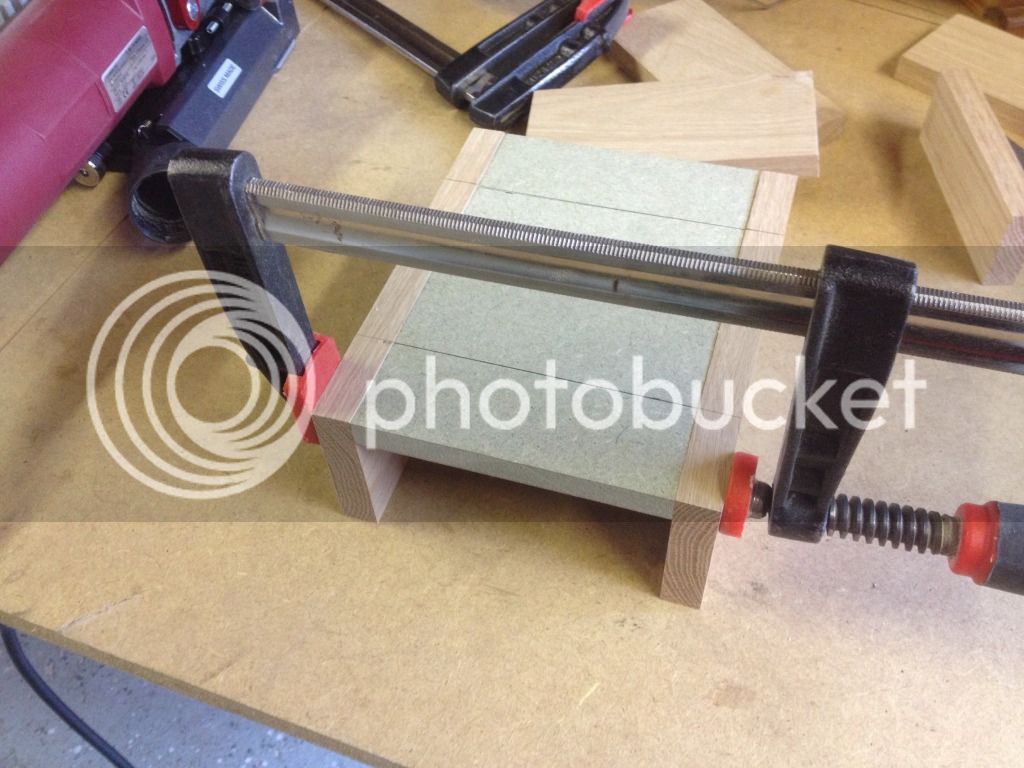

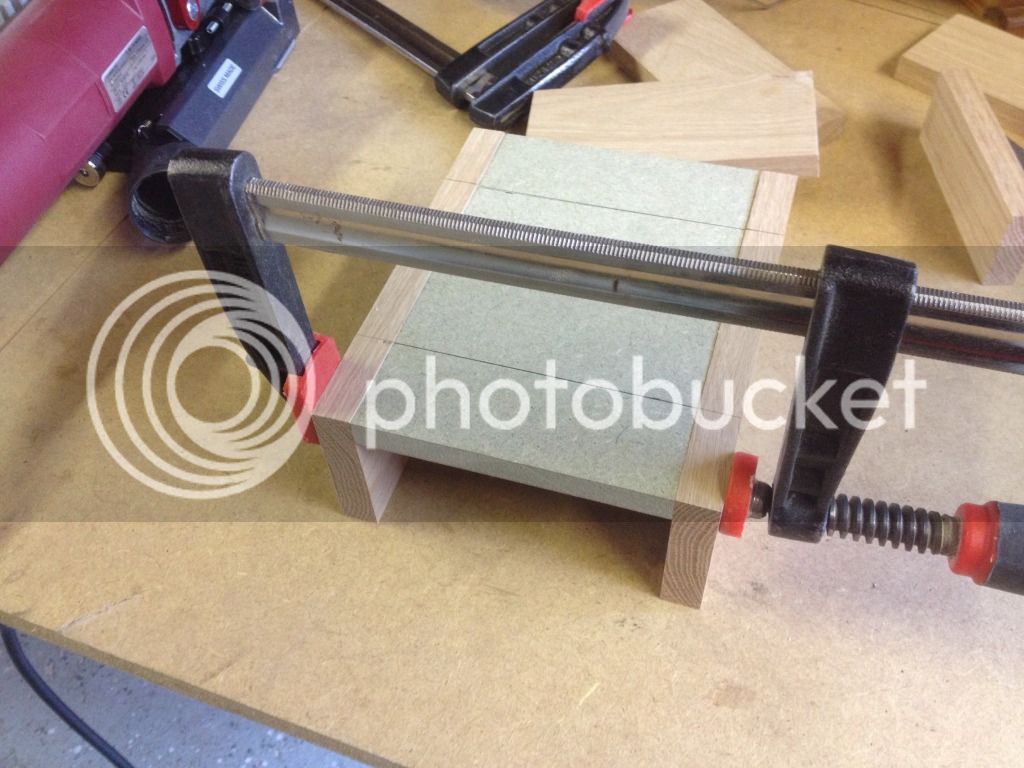

Dry fit to check everything's nice.

2 biscuits along each side and a groove along to long back edges and one on the top panel for the removable back.

Left the back panel oversize for the time being.

The piece was made mainly from solid oak with a veneered front, I basically looked at his daughter version and copied it's methods with a few adaptations, mainly thicker material and a sliding back panel rather than those nasty spinning things you get on the back of picture frames.

I started by cutting the front panel and side panels and assembling from there.

Dry fit to check everything's nice.

2 biscuits along each side and a groove along to long back edges and one on the top panel for the removable back.

Left the back panel oversize for the time being.