Mcluma

Established Member

Bike / Tool Shed

Camera’s on phones are getting better, and better, so there is less reason as to not having pictures. In the past I always had to get the camera, and you never want to leave it lying around, just to have it ready for that one picture moment, whereas you always have a phone with you. So there will be more photo’s to share

My sweet wife has asked for a bike shed. We looked around for ready made ones, however, and I have to admit some of them are really nice looking, they would not give the same feel as our carport, and this shed is going to be next to the carport.

So I will build one from scratch, and I will share the pictures of the build as we go along.

Currently I am using the 3 bay carport also as tool storage, - this was a necessity as we were refurbishing our house, and now the house is finished the wife doesn’t want any tools in the house. The solution is to make the bike shed a bit larger so it can take my 3 large tool racks, workbench, and the table saw

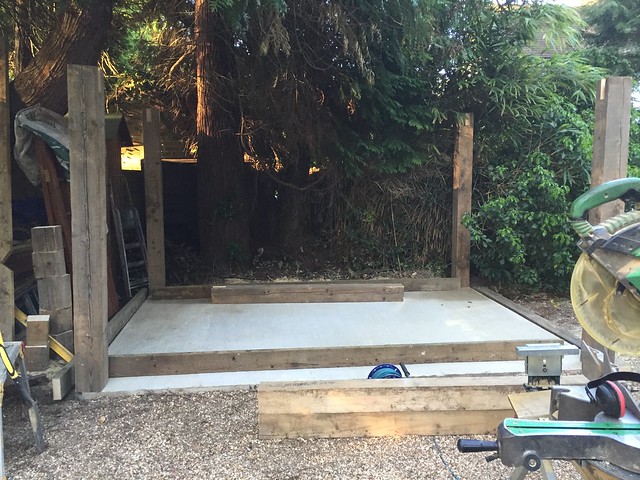

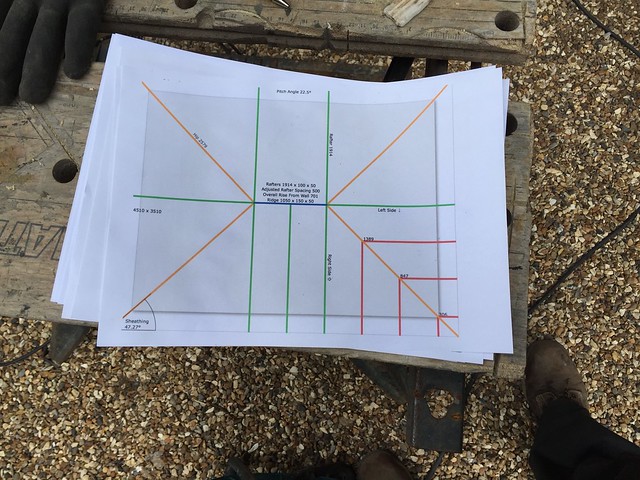

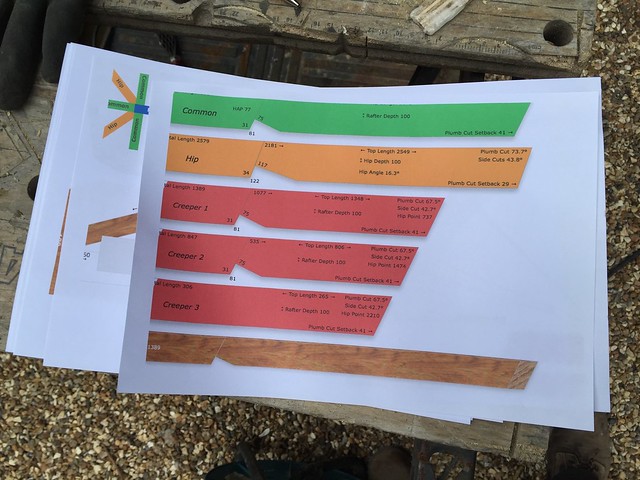

The dimensions will be 3m * 3m with a hipped roof, construction will be very similar to the carport

This is were it needs to be going, it will be half going underneath the tree, and sufficiently away from the fence so there will be ample means for maintenance

Untitled by mcluma, on Flickr

Untitled by mcluma, on Flickr

Picked up the digger from storage, hence the canopy is missing, which makes it a bit easier to work underneath the tree

Untitled by mcluma, on Flickr

Untitled by mcluma, on Flickr

First building material is in for the base, still have enough hardcore, so that was a saving, and will clear up the drive

Untitled by mcluma, on Flickr

Untitled by mcluma, on Flickr

Also picked up some posts

Untitled by mcluma, on Flickr

Untitled by mcluma, on Flickr

Tomorrow its preparation of the ground and with a bit of luck putting the base down, otherwise it will be Sunday

Camera’s on phones are getting better, and better, so there is less reason as to not having pictures. In the past I always had to get the camera, and you never want to leave it lying around, just to have it ready for that one picture moment, whereas you always have a phone with you. So there will be more photo’s to share

My sweet wife has asked for a bike shed. We looked around for ready made ones, however, and I have to admit some of them are really nice looking, they would not give the same feel as our carport, and this shed is going to be next to the carport.

So I will build one from scratch, and I will share the pictures of the build as we go along.

Currently I am using the 3 bay carport also as tool storage, - this was a necessity as we were refurbishing our house, and now the house is finished the wife doesn’t want any tools in the house. The solution is to make the bike shed a bit larger so it can take my 3 large tool racks, workbench, and the table saw

The dimensions will be 3m * 3m with a hipped roof, construction will be very similar to the carport

This is were it needs to be going, it will be half going underneath the tree, and sufficiently away from the fence so there will be ample means for maintenance

Untitled by mcluma, on Flickr

Untitled by mcluma, on FlickrPicked up the digger from storage, hence the canopy is missing, which makes it a bit easier to work underneath the tree

Untitled by mcluma, on Flickr

Untitled by mcluma, on FlickrFirst building material is in for the base, still have enough hardcore, so that was a saving, and will clear up the drive

Untitled by mcluma, on Flickr

Untitled by mcluma, on FlickrAlso picked up some posts

Untitled by mcluma, on Flickr

Untitled by mcluma, on FlickrTomorrow its preparation of the ground and with a bit of luck putting the base down, otherwise it will be Sunday