Had a fun day with fitting the doors, first up was to reducing its overall size to match the other door, which I did by cutting down the top rail.

This is how I left it last week

Untitled

Untitled by

Chris, on Flickr

And after cutting down the top rail

Untitled

Untitled by

Chris, on Flickr

So now they are the same size

Untitled

Untitled by

Chris, on Flickr

Next up was cutting in the hinges, and I noticed that on these doors the hinges are cut in on an angle inwards. I have never seen that before. Have no idea what the added benefit of doing it that way is!! – beats me

Untitled

Untitled by

Chris, on Flickr

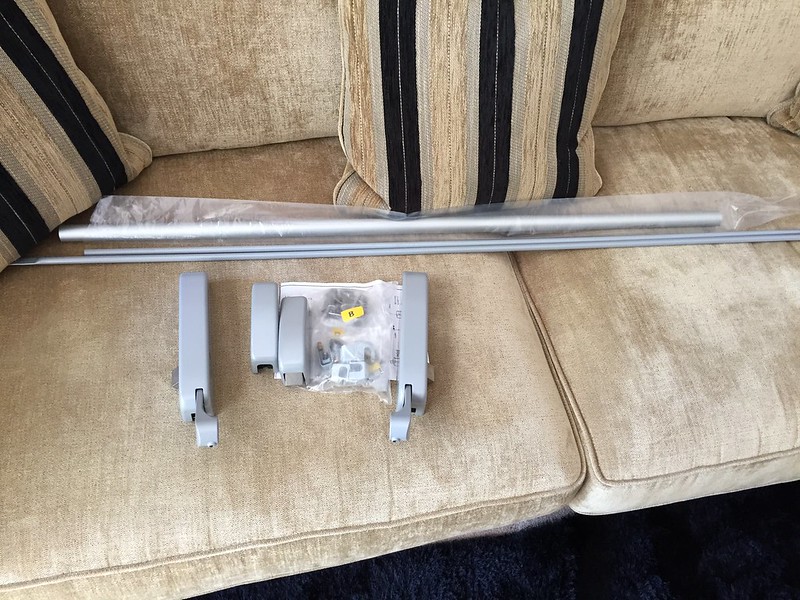

The hinges that where on the doors are heavy duty ones, but they will not do it for me. (I will explain, and show later!) I replaced them with these hinges

Untitled

Untitled by

Chris, on Flickr

Untitled

Untitled by

Chris, on Flickr

I had these left over from another project which I did about 2 years ago- my secret door project

Little side step –I hope you don’t mind!

I bought these doors (actually it was my wife who bought them), which are very heavy MDF panel doors,

Doors2

Doors2 by

Chris, on Flickr

But that is not the part I bought them for, this is the other side of them

Doors1

Doors1 by

Chris, on Flickr

Doors4

Doors4 by

Chris, on Flickr

Doors3

Doors3 by

Chris, on Flickr

These are Faux leather books, real books, but prepared specially for display purposes.

The doors where utilized in our set-up for the lounge

Untitled

Untitled by

Chris, on Flickr

Untitled

Untitled by

Chris, on Flickr

Indeed a secret door – which gives access to our plant room and the Gym

Untitled

Untitled by

Chris, on Flickr

Untitled

Untitled by

Chris, on Flickr

Ok back to the bike tool shed.

So as I explained, I had these hinges, and because the leave of hinge is very long, it will help the door clearing the wall, therefore the door can open a compleet 180 degrees.

The doors hinges where originally cut in to open inwards. I will let them open outwards

Untitled

Untitled by

Chris, on Flickr

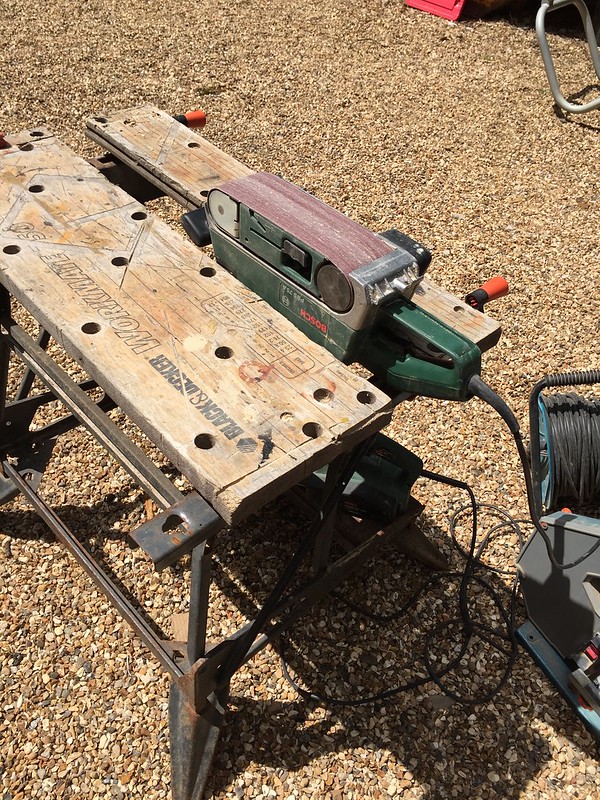

Cutting the hinges free-hand, that is where this little Bosch Router comes in handy

Untitled

Untitled by

Chris, on Flickr

Unfortunately these hinges have square corners, so I need a little with help of the corner chisel.

Untitled

Untitled by

Chris, on Flickr

Prior to routing them out I score the lines with a chisel, that gives then a very clean line when using the router

Untitled

Untitled by

Chris, on Flickr

I have already put a doorframe in place, based on the dimensions of the doors, so no more cutting needs to be done. I offer them up inside the doorframe with a piece of 2mm cardboard underneath so I can mark the hinges on the doorliner

Untitled

Untitled by

Chris, on Flickr

Than a bit more routing and fitting the door

Untitled

Untitled by

Chris, on Flickr

And here you can see what I mean with opening the door a full 180 degrees

Untitled

Untitled by

Chris, on Flickr

Untitled

Untitled by

Chris, on Flickr

That is one door done, now the other, but first I have to fill in the hole where the letterbox once was. I quickly knock up a jig, that will lift my router just above the bow of the window, as that was in the way

Untitled

Untitled by

Chris, on Flickr

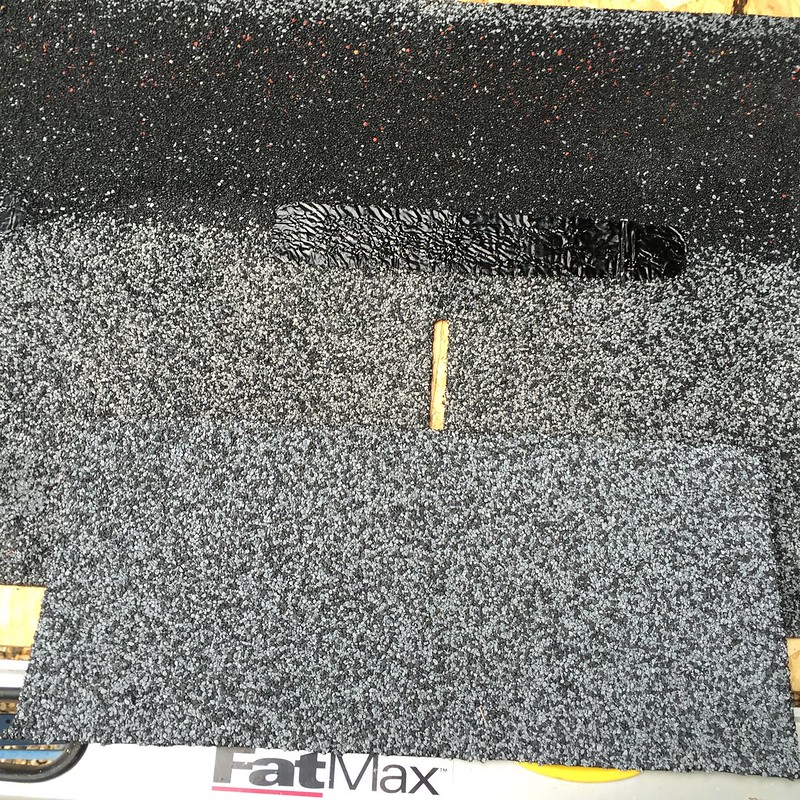

Filled IT with a piece of white oak. It doesn’t look pretty now, but when it’s all painted it will look fine – sanded it down with the belt sander

Untitled

Untitled by

Chris, on Flickr

Untitled

Untitled by

Chris, on Flickr

Fitted, and as you can see I also filled the holes in the other door

Untitled

Untitled by

Chris, on Flickr

To keep the doors a wide as possible, I had to forgo on a rebate, to ensure the doors are water and wind tight, I fitted a pairmaker. The pairmaker also helped me to even out the styles, as one style was wider by about 15mm.

Untitled

Untitled by

Chris, on Flickr

Untitled

Untitled by

Chris, on Flickr

Tomorrow I need to look for a locking mechanism.