You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

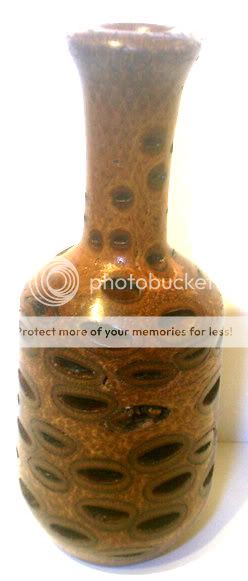

Banksia Nut!!

- Thread starter THOMASB

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Bodrighy

Established Member

Very nice piece but I bet you are still picking the fluff out of your hair? :lol:

I have tried this but unlike you never succeeded. Had a real problem keeping the thing on the lathe. How did you do it?

Pete

I have tried this but unlike you never succeeded. Had a real problem keeping the thing on the lathe. How did you do it?

Pete

CHJ

Established Member

Well done Thomas, looks like yours was a slightly different cultivar to the only one I have tried, mine had no continuous hard core as such and only held together by dint of sealer.

NEVER AGAIN, three days battling the results of being exposed to the dust was enough.

NEVER AGAIN, three days battling the results of being exposed to the dust was enough.

Jenx

Established Member

- Joined

- 27 Sep 2007

- Messages

- 1,978

- Reaction score

- 0

Well Done, Thomas ! How did you find the procedure of turning it ?

I'm led to believe it fights back with some degree of spirit !

The guy where I get most of my wood imported 3 tons of the things just before christmas, and he's shifting them reasonably well ( I was up there today and talking about them ! )

... I've so far 'shy'd away from them.. for much the reasons as Chas describes, and for the flying little razors that allegedly fly out of them !

Notwithstanding the 'properties' of Mr Banksia Grandis ... you've made a super job of the vase / weedpot ... its great !

8) 8) 8) 8) 8)

I'm led to believe it fights back with some degree of spirit !

The guy where I get most of my wood imported 3 tons of the things just before christmas, and he's shifting them reasonably well ( I was up there today and talking about them ! )

... I've so far 'shy'd away from them.. for much the reasons as Chas describes, and for the flying little razors that allegedly fly out of them !

Notwithstanding the 'properties' of Mr Banksia Grandis ... you've made a super job of the vase / weedpot ... its great !

8) 8) 8) 8) 8)

PowerTool

Established Member

Banksia nuts - the Devils gift to woodturners :wink:

Odd how most of us have only ever turned one..

Very nice finished piece,though

Andrew

Odd how most of us have only ever turned one..

Very nice finished piece,though

Andrew

planetWayne

Established Member

I always did wonder about these, I notice that Axminster sell these to as something to cut your teeth on.

I did wonder though, how big are they!? Are we talking coconut size things or bigger?

Cheers

Wayne.

I did wonder though, how big are they!? Are we talking coconut size things or bigger?

Cheers

Wayne.

big soft moose

Established Member

- Joined

- 22 May 2008

- Messages

- 5,079

- Reaction score

- 0

they vary quite a bit , but on average they are about as long as a coconut on their longer dimension but nowehere near as far round (probably arround the same circumference as a tin of lager).

there are two main problems in turning them

a) getting a grip on the bloody things - between centres is the only realistic way to go unless you bandsaw one end off and hold it in a chuck

b) some people are allergic to their dust ( I wear latex gloves when turning them - latex because if it catches on the spindle it will rip rather than drag my fingers in- plus long sleves and an air shield), plus they throw out loads of fluff and cack - I've made a few night light holders etc (because swimbo thought they looked interesting) but they arent something i'd reccomend anyone to try just for the hell of it.

there are two main problems in turning them

a) getting a grip on the bloody things - between centres is the only realistic way to go unless you bandsaw one end off and hold it in a chuck

b) some people are allergic to their dust ( I wear latex gloves when turning them - latex because if it catches on the spindle it will rip rather than drag my fingers in- plus long sleves and an air shield), plus they throw out loads of fluff and cack - I've made a few night light holders etc (because swimbo thought they looked interesting) but they arent something i'd reccomend anyone to try just for the hell of it.

Well Done Thomas,

Obviously a brave man and I agree with everyone elses comments because I cut one in half and turned it part way to a mushroom and gave up!

The shrapnell and the fluff is terrible and the only answer is to be armour plated like a welder but with an air filtered visor!

Can't say I have felt the urge to have another go.

The length usually varies between 5 and 8 inches and up to 3 inch diameter

Regards,

Ian

Obviously a brave man and I agree with everyone elses comments because I cut one in half and turned it part way to a mushroom and gave up!

The shrapnell and the fluff is terrible and the only answer is to be armour plated like a welder but with an air filtered visor!

Can't say I have felt the urge to have another go.

The length usually varies between 5 and 8 inches and up to 3 inch diameter

Regards,

Ian

planetWayne

Established Member

Well - I'm impressed anyways

For some reason I must admit - I did think they would be bigger than a larger tin

They just look bigger in the photo's :-o

Cheers

Wayne.

For some reason I must admit - I did think they would be bigger than a larger tin

They just look bigger in the photo's :-o

Cheers

Wayne.

johnny.t.

Established Member

That looks great Thomas, like so many little mouths 8)

JT

JT

Happy amateur

Established Member

Turn It In":2l71bk51 said:The shrapnell and the fluff is terrible and the only answer is to be armour plated like a welder but with an air filtered visor!

It is advisable to remove any "seeds" that are in the holes.

They are arrowhead shape and very very sharp. They have been known to embed themselves in concrete walls if not removed.

Evil things

Fred

mikec

Established Member

Have turned a few, loads of fluff, shrapnel and missiles if the seeds are still in :shock:

Best results from cutting across square at each end and turning between centres. I use a leather gauntlet when roughing down to size.

They take a good finish and have loads of potential for playing around with different fillers in the holes.

Regards,

Mike C

Best results from cutting across square at each end and turning between centres. I use a leather gauntlet when roughing down to size.

They take a good finish and have loads of potential for playing around with different fillers in the holes.

Regards,

Mike C

Thanks for the comments, should have asked before turning one!!

Has Mikec said cut each end square, did some shaping, turned a tenon for my chuck, tailstock for support, finish shaping, drilled a 10mm hole, shaped the top, finished with two sanding sealer brushed on to get some in the holes, little BLO, two friction polish, and some buffing.

May never turn one again, guess I was lucky :roll: :roll:

Has Mikec said cut each end square, did some shaping, turned a tenon for my chuck, tailstock for support, finish shaping, drilled a 10mm hole, shaped the top, finished with two sanding sealer brushed on to get some in the holes, little BLO, two friction polish, and some buffing.

May never turn one again, guess I was lucky :roll: :roll:

DaveL

Established Member

Well when I picked up my new lathe, Simon gave me one of these, he had bought two but said one should be enough for anybody. :twisted:THOMASB":2avm4irl said:May never turn one again, guess I was lucky :roll: :roll:

SVB

Established Member

Sorry Dave - I thought of handing over that bl**dy nut when I first read this thread. Looking forward to seeing your wip with it!

Simon.

Simon.

Bodrighy

Established Member

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 9

- Views

- 1K