PeterBassett

Established Member

Hi all.

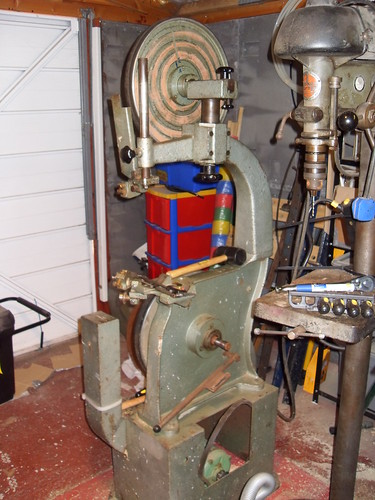

I bought a Multico 16" bandsaw last week and it is in need of a little TLC. I've started striping it down to clean and check it over and I need some advice on the top wheel bearings.

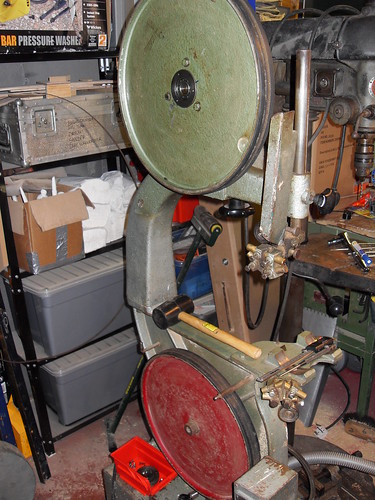

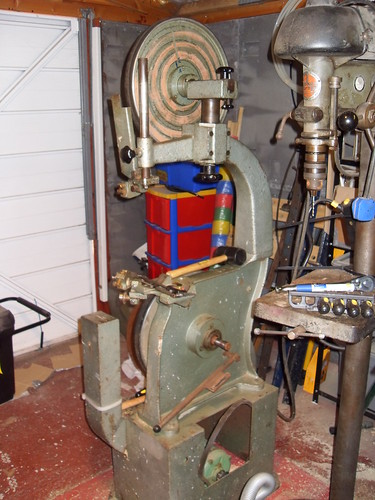

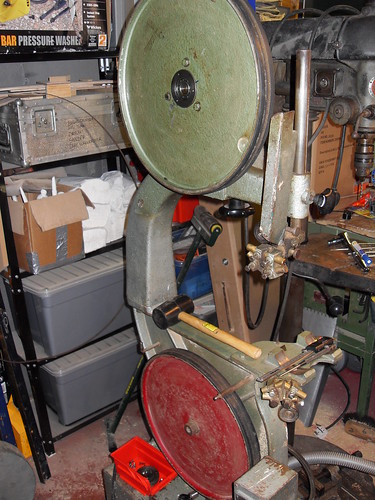

Firstly, this is the machine (as of this evening)

All the guards are off, the table is off and already mostly clean. It was covered in globby paint.

I need some advice on the top wheel bearing which is louder than the bottom and doesn't spin for as long. I have a video of a comparison between the two here.

http://www.flickr.com/photos/petebassett/4707551200/

You can hear the top bearing quite well and the bottom one is barely audible.

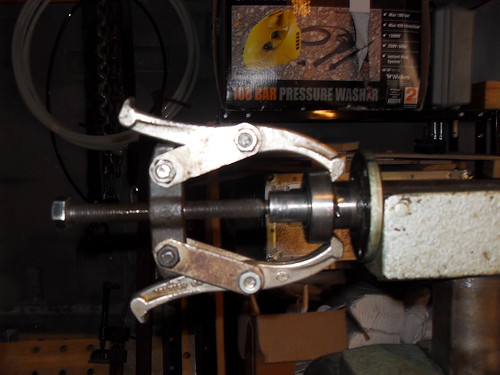

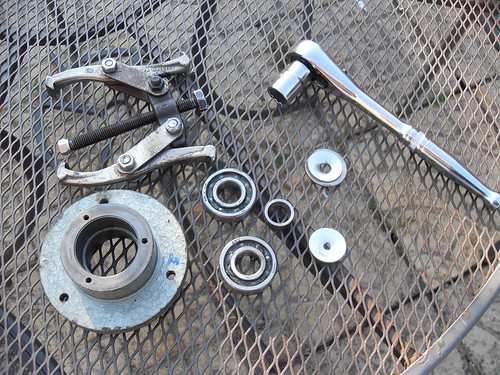

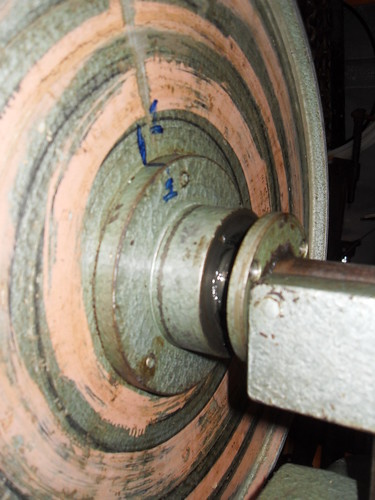

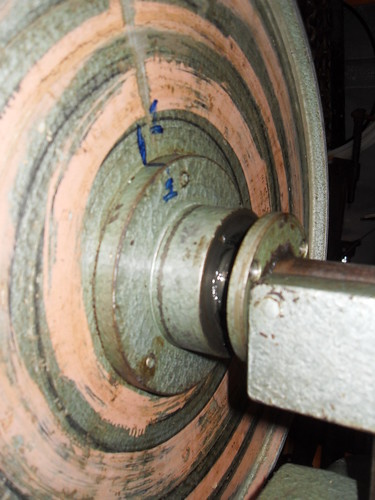

I decided to take the wheel off to change the bearings but that has proven to be more difficult than I had expected. I have removed the outside bearing cover. Here you can see the outer bearing (I assume there are two). It is marked SKF, which I believe are pretty good.

and the inside cover

but the wheel will not some off the shaft using reasonable hand strength. I thought better of trying anything else until I'd had a second opinion, so I put it back together.

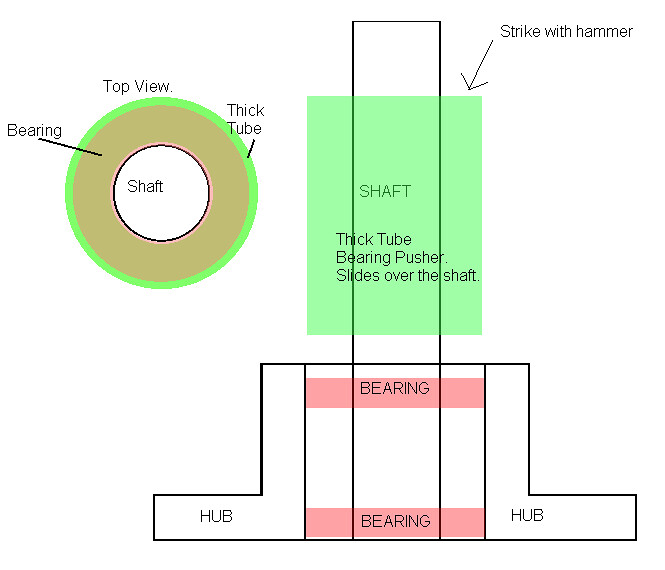

So, how hard should it be to get the wheel hub off the shaft? Is it a bearing puller job?

The hub had a grease nipple and the inside is packed with grease, will the new bearing need to be of the same type?

Anyones thoughts on this would be greatfully accepted!

Cheers all.

Pete

I bought a Multico 16" bandsaw last week and it is in need of a little TLC. I've started striping it down to clean and check it over and I need some advice on the top wheel bearings.

Firstly, this is the machine (as of this evening)

All the guards are off, the table is off and already mostly clean. It was covered in globby paint.

I need some advice on the top wheel bearing which is louder than the bottom and doesn't spin for as long. I have a video of a comparison between the two here.

http://www.flickr.com/photos/petebassett/4707551200/

You can hear the top bearing quite well and the bottom one is barely audible.

I decided to take the wheel off to change the bearings but that has proven to be more difficult than I had expected. I have removed the outside bearing cover. Here you can see the outer bearing (I assume there are two). It is marked SKF, which I believe are pretty good.

and the inside cover

but the wheel will not some off the shaft using reasonable hand strength. I thought better of trying anything else until I'd had a second opinion, so I put it back together.

So, how hard should it be to get the wheel hub off the shaft? Is it a bearing puller job?

The hub had a grease nipple and the inside is packed with grease, will the new bearing need to be of the same type?

Anyones thoughts on this would be greatfully accepted!

Cheers all.

Pete