Very Nice,

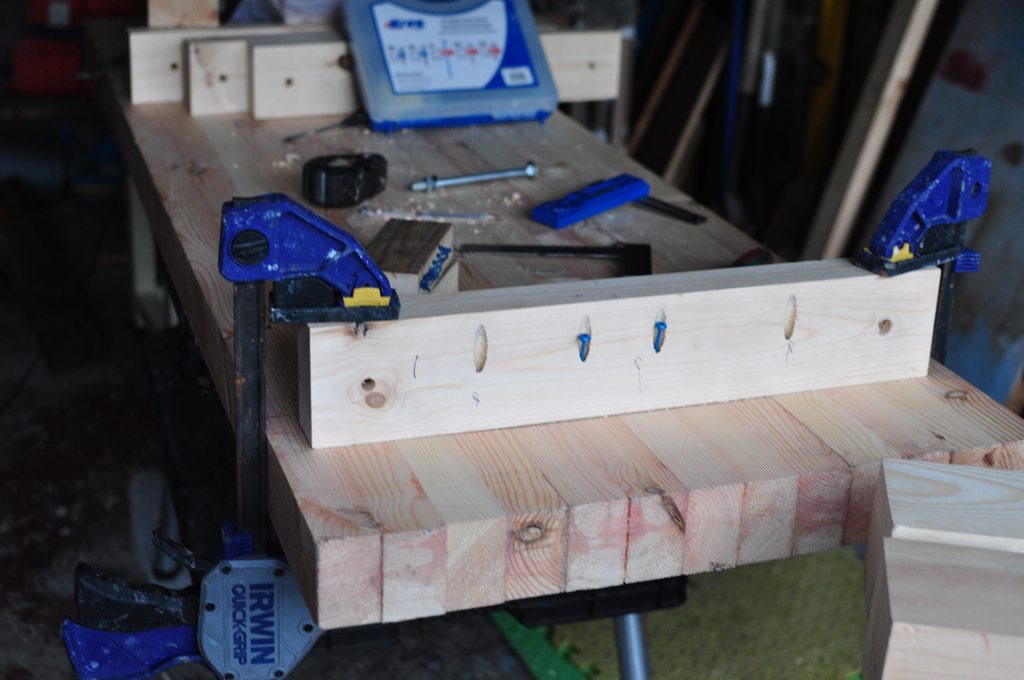

I'm back from holiday and having a whole load of problems with one of the laminations, typically the middle one.

Without noticing it seems to have been glue'd stepped at one side (my camera was being stubborn yesterday, so i've mocked the issues up in sketchup.)

So this was how it came out (i've exagerated it in the drawing.)

The first thing i did was to plane down the top surface, in hindsight the way i did this, may have been a mistake!

Now i have a flat surface, or near to, but looking at the sticks, it is still sloping to the front right corner.

Using a square, referencing the top surface i've planed... there is a gap at the bottom left side, and on the opposite side there's a gap at the top.

My question is, what is the best way to rectify this? my thoughts was to (assume... the sides are parrallel) and contnue planing the top left side, then when the left top side/left side is dead square, try and continue flattening this plane across the top, which should remove the low side on the right.

Is this correct? i don't want to just randomly keep planing things off as i could be making it worse for all i know.

(I'm trying to get the sides square to the top, so i can joint the three laminations for the top together without too much trouble... or should i just flatten the sides, joint it and worry about the top then? the only issue with that is i wasn't then sure what i would be trying to line up the top with.

Cheers

Mark