A few things to note if you have the same model with ST. I may have noted them above, but perhaps in a disjointed way.

The front and back rails can be mounted in two positions.

If you mount in the "intended" position, you will need to cut off about 12" from the left side to fit the ST.

If you mount one hole along to the right, you still need to cut off only the front rail (box only not the actual rail).

The benefit of the latter is that you get more rail to the right. The downside is that then the gaps for the mitre slots won't line up and you will also need to make new cut outs for this.

As another member suggested, i cut off the end then remounted the plastic cap.

DO NOT stick on the tape until you are completely finished!

The mark for the tape can be fitted to right or left side. choose which side BEFORE you cut and stick the tape on!

Get the saw blade parallel to mitre slots before you fit the sliding table.

For me the router table is just in the wrong place, you can't stand in front of it. maybe one can put it the other way round from the picture i posted above, however as I don't have this I can't comment on the router setup.

I made my sliding table a hair above the main table so that boards on the sliding table don't catch on the main table.

Getting the sliding table parallel and square, and adjusting the legs is awkward, so you really don't want to have to move this afterwards. Also the mobile base is out when you have the TS/RT.

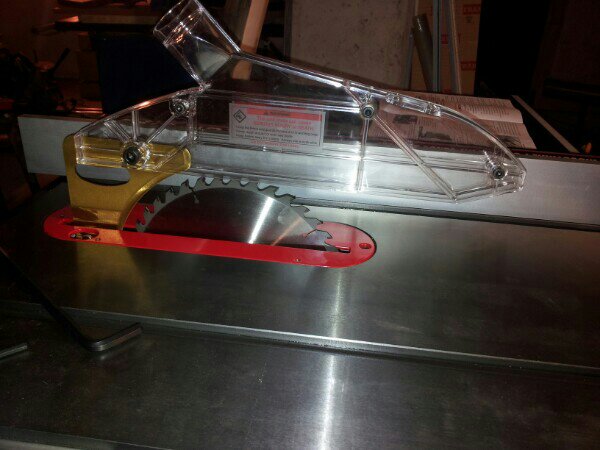

If I think of anything else I will add it. Here's some more photos, showing the decent sliding table capacity.