Hi everyone,

I would like to find out the different ways people deal with their workshop waste i.e. offcuts, wood/mdf dust etc.

We currently use large 1100l bins for our offcuts (after cutting them down to approximately A4 size), a recycling bin for cardboard and plastics and a separate collection for our extraction bags of dust/chippings. The dust is a mix of soft/hard wood, chipboard and mdf. Each bag is always mixed.

It's the bags of dust/chippings that we're having the most issues with, the collector has just tripled his price due to the weight of the bags.

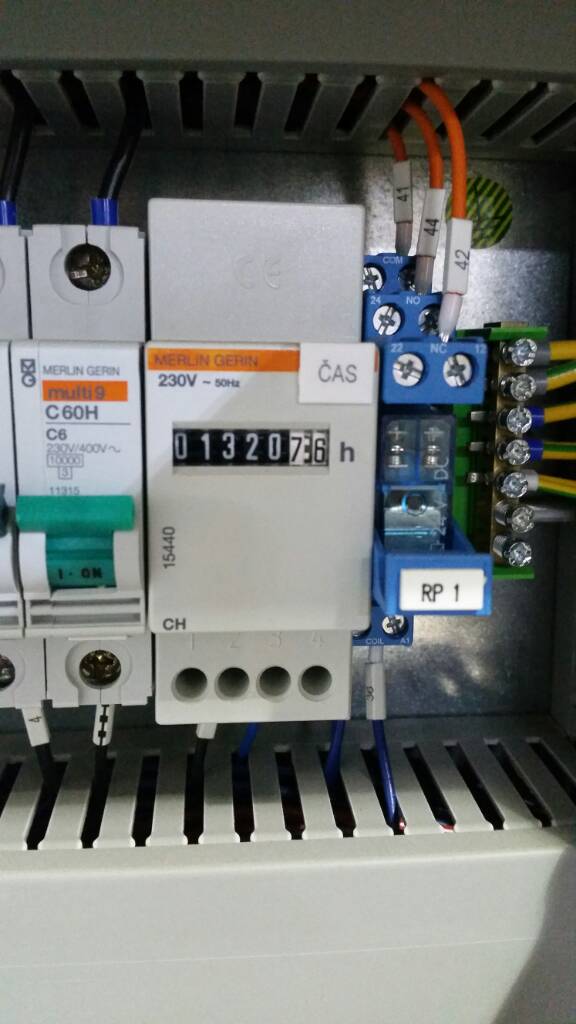

In an ideal world we'd purchase a wood burner but we'd prefer not to in our current set-up, similarly a briquette maker would be great but then we need to take the time to feed it 9 BIG bags a week.

We're London based and would love a cost effective solution for the dust/chipping collection.

Any advice would be great!

Thanks in advance

I would like to find out the different ways people deal with their workshop waste i.e. offcuts, wood/mdf dust etc.

We currently use large 1100l bins for our offcuts (after cutting them down to approximately A4 size), a recycling bin for cardboard and plastics and a separate collection for our extraction bags of dust/chippings. The dust is a mix of soft/hard wood, chipboard and mdf. Each bag is always mixed.

It's the bags of dust/chippings that we're having the most issues with, the collector has just tripled his price due to the weight of the bags.

In an ideal world we'd purchase a wood burner but we'd prefer not to in our current set-up, similarly a briquette maker would be great but then we need to take the time to feed it 9 BIG bags a week.

We're London based and would love a cost effective solution for the dust/chipping collection.

Any advice would be great!

Thanks in advance