Since this has to store everything but not be too big and clunky we decided that anything not actually necessary, like legs for example, should be left out.

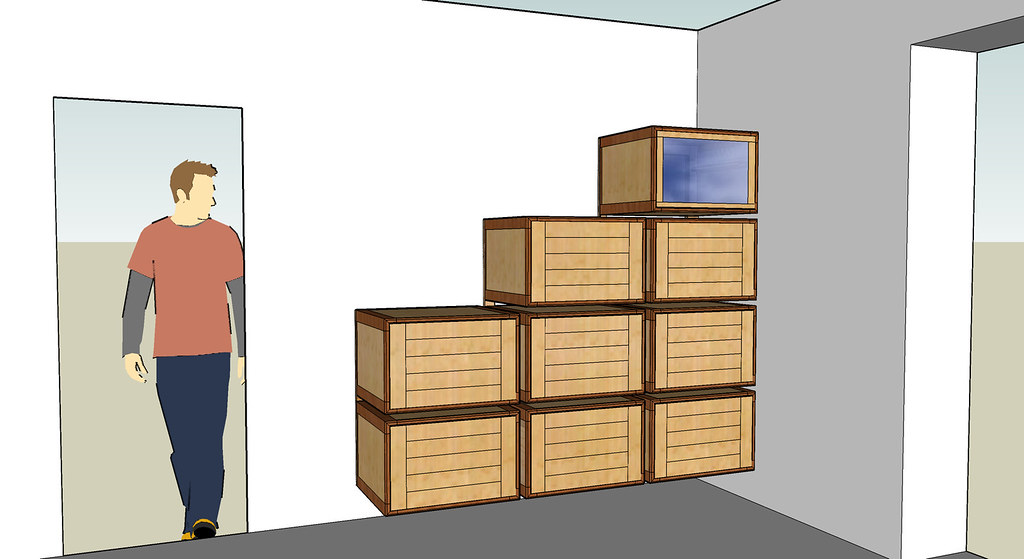

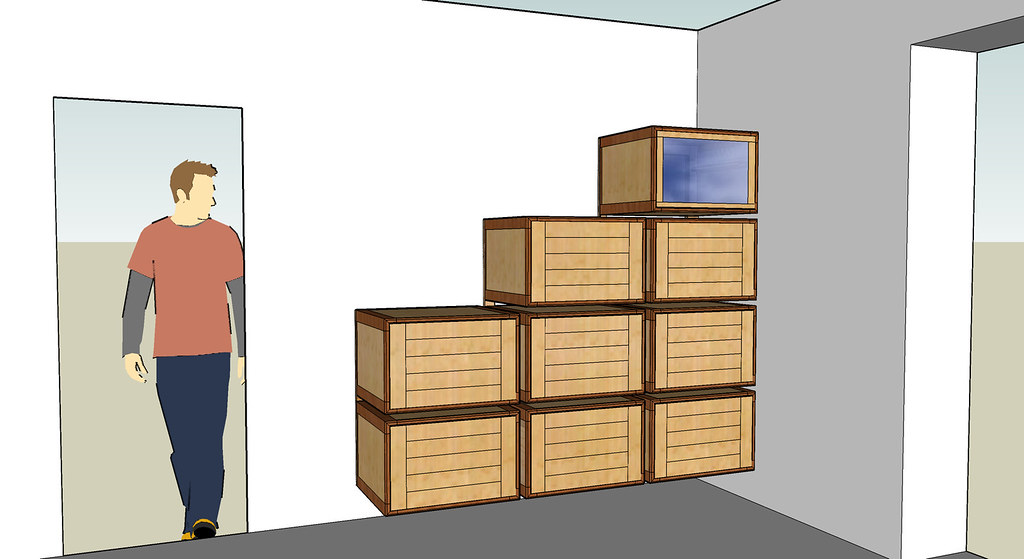

This is what we came up with. Identical carcasses should mean reasonably rapid construction.

Some of the fronts will be split across to form two drawers.

Boxes could be arranged in different patterns if we change our minds after construction.

I am looking forward to seeing what actually results. I like the fact that in this comp design evolution is to be expected.

This is what we came up with. Identical carcasses should mean reasonably rapid construction.

Some of the fronts will be split across to form two drawers.

Boxes could be arranged in different patterns if we change our minds after construction.

I am looking forward to seeing what actually results. I like the fact that in this comp design evolution is to be expected.