Hey everyone, hope your all having a great christmas !

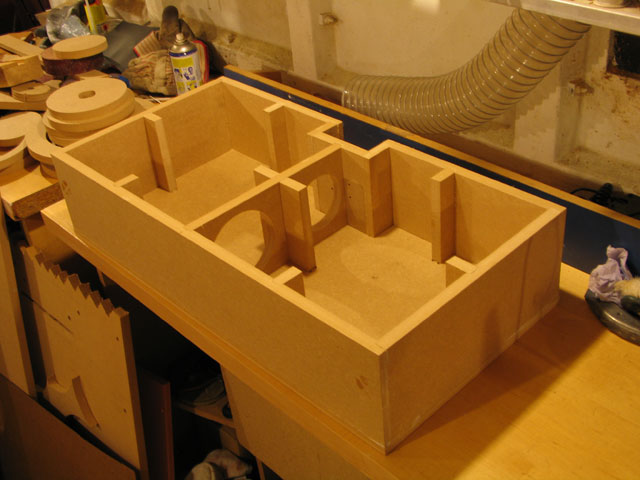

So im currently having my garage / workshop extended by another 6 x 4 meters so i would like to get a decent table saw in there, Im looking to build my own speaker cabinets in the near future, so ideally i want to be able to rip up 6x4 sheets of ply, mdf etc but im a little unsure what i should be looking for in a table saw in terms of praticality and accuracy.

I have seen a few people take their table saws and mount them into a workbench to give extra workspace, i love this idea but i would then need to make or purchase an additional fence system to run the full length of the table.

I currently have a Dewalt DW472 flipsaw which im going to stick on ebay, its breat but not so great as a table say, the fence only lock from one side of the table and there is to much movement in the fence when ripping sheets of wood down.

So, im thinking should i buy a light jobsite table sav and mount it in a large table, such as the Dewalt DW745 or am i better buying a stand alone machine, i have seen this Charnwood on ebay,

http://www.ebay.co.uk/itm/221582375654? ... EBIDX%3AIT

However the motor is only 11002 whers as the dewalt is 1700w.

Can anyone give me some advice as to which is going to give me the more accurate cuts etc, i dont really want a great big machine taking up all the sapce and love the idea on mounting one in a table as when the saw is not in use, you can lower the blade and its then back in storage !

love this !

http://tableplanpdf.com/wp-content/uplo ... lans-3.jpg

any advice would be most appreciated.

So im currently having my garage / workshop extended by another 6 x 4 meters so i would like to get a decent table saw in there, Im looking to build my own speaker cabinets in the near future, so ideally i want to be able to rip up 6x4 sheets of ply, mdf etc but im a little unsure what i should be looking for in a table saw in terms of praticality and accuracy.

I have seen a few people take their table saws and mount them into a workbench to give extra workspace, i love this idea but i would then need to make or purchase an additional fence system to run the full length of the table.

I currently have a Dewalt DW472 flipsaw which im going to stick on ebay, its breat but not so great as a table say, the fence only lock from one side of the table and there is to much movement in the fence when ripping sheets of wood down.

So, im thinking should i buy a light jobsite table sav and mount it in a large table, such as the Dewalt DW745 or am i better buying a stand alone machine, i have seen this Charnwood on ebay,

http://www.ebay.co.uk/itm/221582375654? ... EBIDX%3AIT

However the motor is only 11002 whers as the dewalt is 1700w.

Can anyone give me some advice as to which is going to give me the more accurate cuts etc, i dont really want a great big machine taking up all the sapce and love the idea on mounting one in a table as when the saw is not in use, you can lower the blade and its then back in storage !

love this !

http://tableplanpdf.com/wp-content/uplo ... lans-3.jpg

any advice would be most appreciated.