Something large with a flange mounted motor for adjustability/alignment purposes

narrows it down to few, those with solid cast iron wheels, seemingly narrows it further,

That's your answer for a no compromise result of a guaranteed smooth running,

vibration free machine.

Just make sure the wheels are solid with a good hands on look, i.e no wheel bore issues,

and balanced wheels would be a good start.

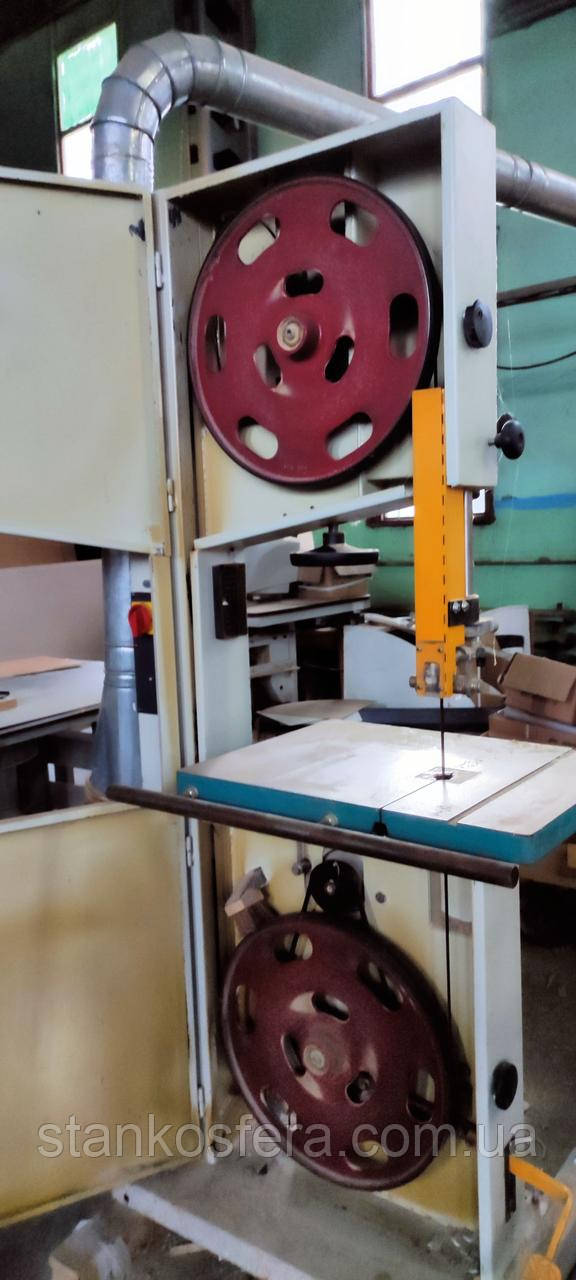

The Compact(ish) CO 450, generous cast iron table.

View attachment 170191

a CO 500, which I can't get a picture of, or a CO 600 below..

View attachment 170190

Depending on which flavour of Centauro CO I'm talking about,

one may find it more appealing to look for one,

which along with the flange mounted motor

(pictured above) not all of them, but most feature this...

has grooved wheels to take the quick change snap on tires with the tongue.

Time is money kinda thing, the machine would likely be in good nick for starters, with a price reflected.

I guess the earlier white ones is about that timeline, check around the back.

Though if not bothered about making a flange or face mount motor adjustable to suit the

wheels, (I say that as most Italian machines feature an adjustable lower wheel)

then something closer to the weight of the Centauro CO machines, with vulcanized rubber tires

could likely be bought cheaply, if it's of a good age, the tires would likely be in tatters, and need dressing to a crowned profile again.

Some older CO machines with solid wheels have vulcanized wheels also, and some of the oldest flavours of those CO's have spoked wheels too, so they might be bought for the same money if rough.

Anyway, provided the wheels are checked over again, and everything was checked in spec beforehand, some differing parts might be used on some, so worth a good look over, with both doors open on the pics to see....

One might even choose to go for solid flywheel flavour of Italian machine if choosy,

ala Griggio SNA 500

(That's very very obviously a good one below, and I'm not just talking about the brake, wot's not on my 600)

or Felder FB series, both only available used, same chassis, possibly guides, notably if so,the lower ones may or may not be the Euro type GL system rollers, also on some Wadkin machines.

Those are perhaps more manageable to lift, well when it comes to the 600 sized saws, what's something like 50kg lighter than the Centauro offerings,

The next size up from them is the 40 series, noteworthy with the column differing

but worth knowing, you might want to check the

HP rating of some, as many of these have 2hp motors,

and I'm unsure if they have solid wheels, wouldn't be surprised to see both flavours optional.

I haven't looked into those FB machines all that much, but perhaps it may be possible to

find a newer one, which may have a more powerful motor?...

Not sure if they ever specced other than the FB500 and FB540 and perhaps made a

550, I doubt it, and tire choice if wanting stretch on butyl rubber like band might be quite difficult to source...

and of those Italian machines mentioned, one might place some value on a non tapered choices of column as is with the Centauro CO, though they do make an equally hefty saw, probably in the same league to the SNAC,

the SP series with square column, that is...

The sloped column of the 40 series, also looks a tad less handy to lay down nicely

but I could be mistaken,

and then there's other varieties from Italian manufacturers, Meber also looks a tad more faff

to lay down,(with table removed obviously)

as if a chok is placed around the middle, it could see-saw about, lifting the base off the ground (which stops it from rolling)

(of which there are many styles of, near every Italian company does something different there)

for transport/logistics, lending more to the domestic woodworker, and not someone with a forklift)

and wanting the extra little bit under the guides compared, might be preferred of those.

Lesser guides and rubber/cork tires may feature on the slightly cheaper flavours.

Regardless of which, spoked vs solid having wheels to suit the more standard size range of the 450, 500 or 540, or 600 or 640, the "40" heavier duty what's becoming the norm, machines...

might be a wise choice if the rubber is perished, though not seen an Italian machine with such evidence of real rubber tires, (not stretch on type) doing such.

It's an option for someone with a budget of say five or six hundred quid, (if willing to wait)

PS I'll leave the Wadkin's out for others to mention, I've got no experience with those.

and I suppose also leave out the Far Eastern machine's, not the run of the mill cheaper ones,

normally featuring the slot to the side of the table,

but the ones what's designed to compete with the Italian's, and generally much heavier for good measure, though worth checking the motor mounting as still not guaranteed success right of the bat, unlike the better designed CO machines.

Possibly Multico might be worth a mention also, in that regards, though not got a good look at the wheel(

s)

View attachment 170241

In a nutshell, I might add, if I were to envision having the perfect machine, regardless of effort needed, that is... as nothing guaranteed on any machine not featuring an adjustable motor, thats without compromise... i.e longer belt, or be it other shenanigans, or even factoring damage...

That goes for 99% of designs of steel chassis machine made recently.

And...

For someone a bit tight for space, but they don't need to find a cramped Far Eastern 500mm wheeled machine, what's not as nice as the slightly more spacious Italian machines...

It might be the older ACM made Felder 540 likely with the paint scheme shown,

as you'd need to check the HP rating of the green ones.

As said I've not looked those Felders up, but think I've seen 3hp versions.

Suppose a brake might be nice, perhaps on a 500 compared to a 600 which has a much larger table, (though one could likely make an add on table on the smaller 20" saws)

and 3 phase for VFD braking if wanting a tamer starting beast.

If they made a 540 for Felder, with solid wheels, then that would be it.

It t'would need be Centaurolized for vibration and component alignment, that is,

to compare to the foot mounted CO machines.

Hopefully it would lay down as nicely as the SNA machines...

It might be the case that I might just prefer my own 600, as it's not as big when you get used to it, and would be happier with using a 1" blade on it compared, especially if wanting to use

a carbide blade, Google "the amazing Woodmaster CT"

Which I suppose is only a matter of time until those become more readily available and affordable, the 1" flavours will likely be the first size to come along.

Good luck