condeesteso

Established Member

Thought I'd share this with you - it's hard to get everything just right in your workshop, but this storage system is a favourite and I would do it again without hesitation. I built my new workshop about 4 years ago, and by accident around that time I was reading about a wall-hung cabinet on what I think was called French cleats (not sure).

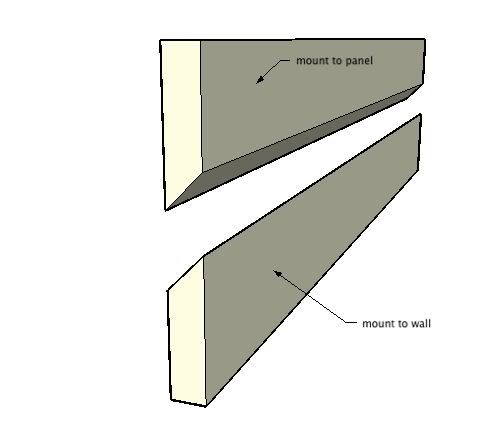

Anyway, I had a load of old oak flooring around, machined it down to about 65 x 22mm, put a 20 degree angle on one short edge, and ran a dado right the way round the workshop, just above door and window frames (which all lined up of course!)

So I can make as many simple wall cabinets, lights etc as I like, and hang them anywhere... even have a move round if I get bored. Most of the cabinets are 12mm birch ply, left over from lining the inner walls.

The angle returns to the wall downward, and an equal / opposite strip runs along top of cabinet, with another 18mm scrap spacer at bottom to keep it vertical. In my experience, 20degrees is ample return angle, so long as forward projection isn't huge - virtually all force is down and there is no way these are coming off.

The simplicity and flexibility it gives is ace, and I just did a blackboard - like the tradition of it, but it is incredibly useful when you need to check dimensions, angles, etc from anywhere around the shop - no more messing around scribbling on the back of some tatty abrasive etc.

Anyway, I had a load of old oak flooring around, machined it down to about 65 x 22mm, put a 20 degree angle on one short edge, and ran a dado right the way round the workshop, just above door and window frames (which all lined up of course!)

So I can make as many simple wall cabinets, lights etc as I like, and hang them anywhere... even have a move round if I get bored. Most of the cabinets are 12mm birch ply, left over from lining the inner walls.

The angle returns to the wall downward, and an equal / opposite strip runs along top of cabinet, with another 18mm scrap spacer at bottom to keep it vertical. In my experience, 20degrees is ample return angle, so long as forward projection isn't huge - virtually all force is down and there is no way these are coming off.

The simplicity and flexibility it gives is ace, and I just did a blackboard - like the tradition of it, but it is incredibly useful when you need to check dimensions, angles, etc from anywhere around the shop - no more messing around scribbling on the back of some tatty abrasive etc.