jimi43

Established Member

I really have to get back to work. All this sitting around mending body bits means that I troll FleaBay and can't resist getting new things to do...

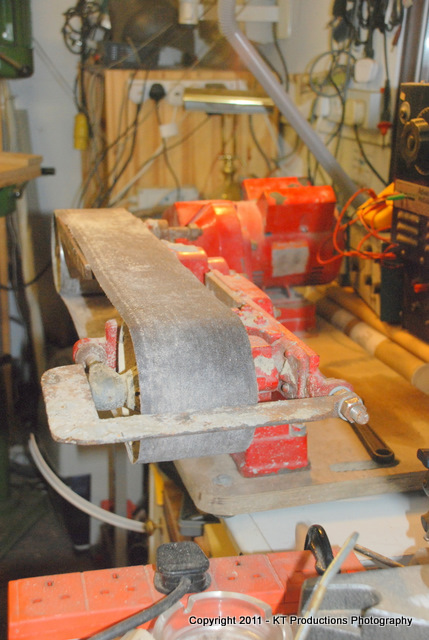

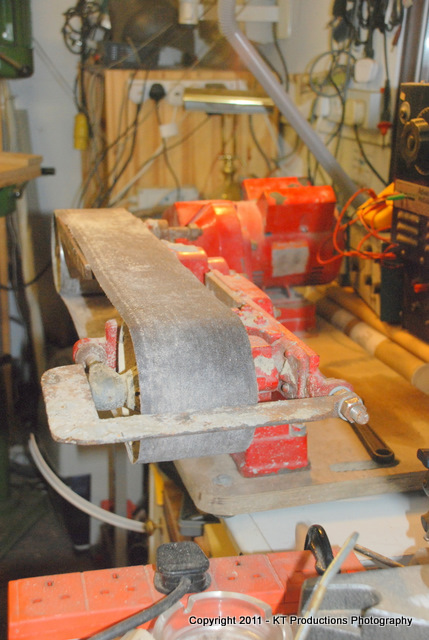

Yesterday I noticed a "little" belt sander that usually is from "some town north of Watford" but happened to be just up the road from me so I bid £40 for it and won! 8)

8)

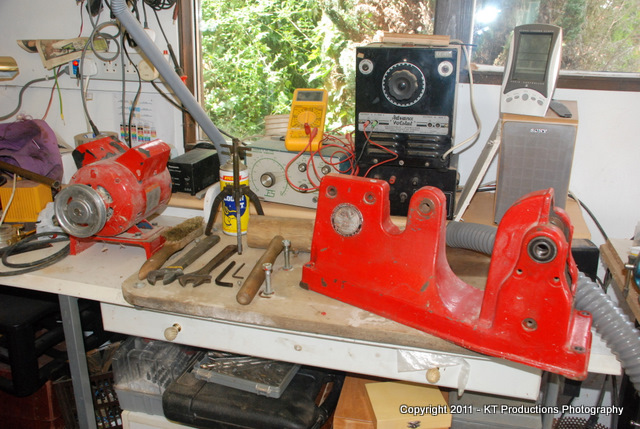

The little sander turned out to be a HUGE Behemoth of good old 30s American engineering...

Unfortunately, someone has painted it fire engine red with Woolies household paint and a cheap brush and then covered the entire machine in concrete!!!!! :lol:

The original badge is there (a plus!)

There is qutie a bit missing....such as the plate on the flat bed...but I have something that will fit that perfectly...

It has a huge Crompton Parkinson motor...

....and another plus...it has 4 spare belts!

....there are a few bent bits....

Anyway...I am off to get some Nitromors tomorrow....and some paint...and a few tins of WD40 and hopefully....just possibly...it might look like this one day....

One day I will learn just to get one from Axminster and be done with it...but where would the fun be in that!

Watch this space for the progress!

Cheers

Jim

Yesterday I noticed a "little" belt sander that usually is from "some town north of Watford" but happened to be just up the road from me so I bid £40 for it and won!

The little sander turned out to be a HUGE Behemoth of good old 30s American engineering...

Unfortunately, someone has painted it fire engine red with Woolies household paint and a cheap brush and then covered the entire machine in concrete!!!!! :lol:

The original badge is there (a plus!)

There is qutie a bit missing....such as the plate on the flat bed...but I have something that will fit that perfectly...

It has a huge Crompton Parkinson motor...

....and another plus...it has 4 spare belts!

....there are a few bent bits....

Anyway...I am off to get some Nitromors tomorrow....and some paint...and a few tins of WD40 and hopefully....just possibly...it might look like this one day....

One day I will learn just to get one from Axminster and be done with it...but where would the fun be in that!

Watch this space for the progress!

Cheers

Jim