Mark,

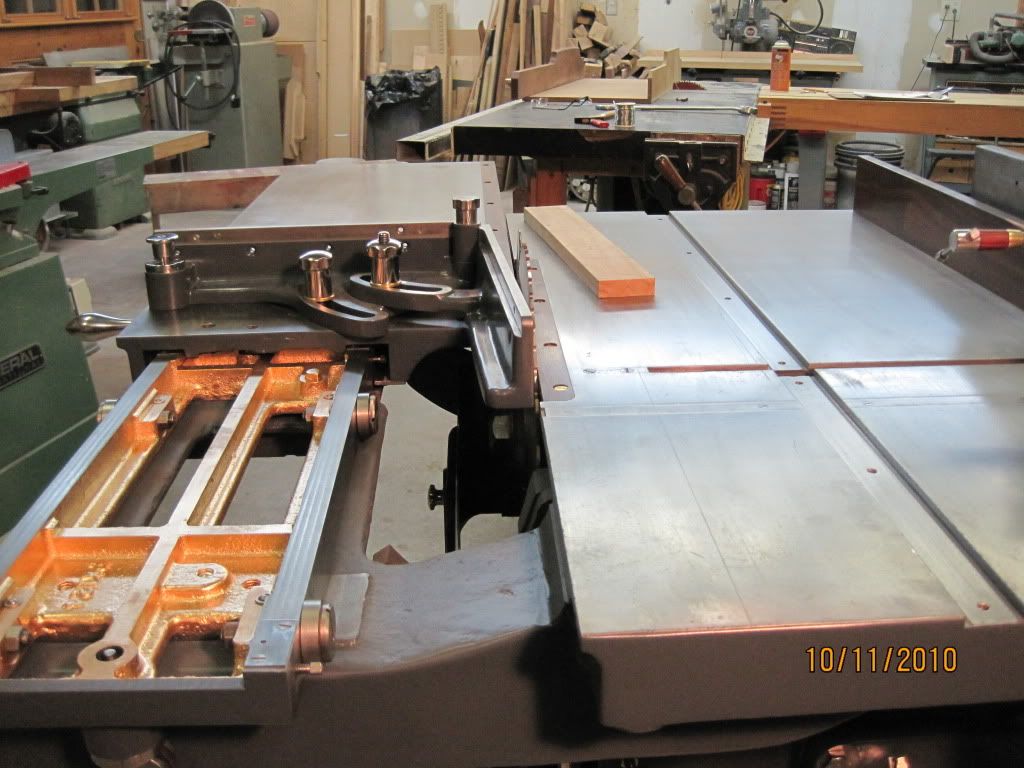

It's not true that there's no industry left in the UK. There's a lot of industry about, but it's changed a lot in the last generation. Yetloh is quite right when he says there are foundries about, but many of them are geared for production runs, and some may not be keen on doing jobbing work, but you can find them. One of the reasons that this is so is because one-off castings are very rare in engineering these days (nobody will bear the costs of patternmaking for just one component), anything of the size of a mitre guide would be fabricated in mild steel - and herein may lie an answer to your problem. There are plenty of small fabrication shops about. You may even be able to make something up yourself, if you have a welding set. Design it carefully so that you do as much preliminary machining (cutting curved slots, etc.) before welding, then the final machining will be just skimming things true. If you can find a fab. shop that can anneal the fabrications for you after welding, even better - this will avoid any distortion on machining as thermal stresses set up on welding are released.

On the table alignment problem, you may be able to make and fit shims between the table and base castings to bring everything level. Make the shims so that they fit as close to the fixing bolts as possible, and of equal thickness all round each bolt to avoid any distortions to the table on applying bolt loads. Try temporarily wedging the tables true with the bolts released, then check each shim gap with feeler gauges to find how much each needs. You can buy shimstock from any good engineer's merchant - or on the web.