SemiSkilled

Established Member

- Joined

- 26 Feb 2008

- Messages

- 33

- Reaction score

- 0

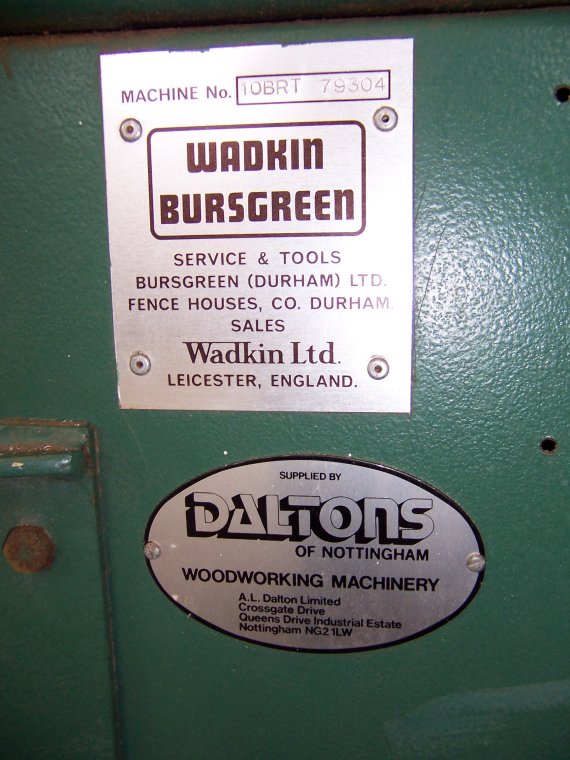

I have recently bought a Wadkin 10"AGS,

I'd like to use a dado saw, in the user instructions it shows a knurled ring to lock the dado saw onto the arbour, which takes the place of the nut.

does any one know the dimensions of this ring ? if I'm going to make it I'll get it as near to the original as I can.

TIA.

Lee.

I'd like to use a dado saw, in the user instructions it shows a knurled ring to lock the dado saw onto the arbour, which takes the place of the nut.

does any one know the dimensions of this ring ? if I'm going to make it I'll get it as near to the original as I can.

TIA.

Lee.