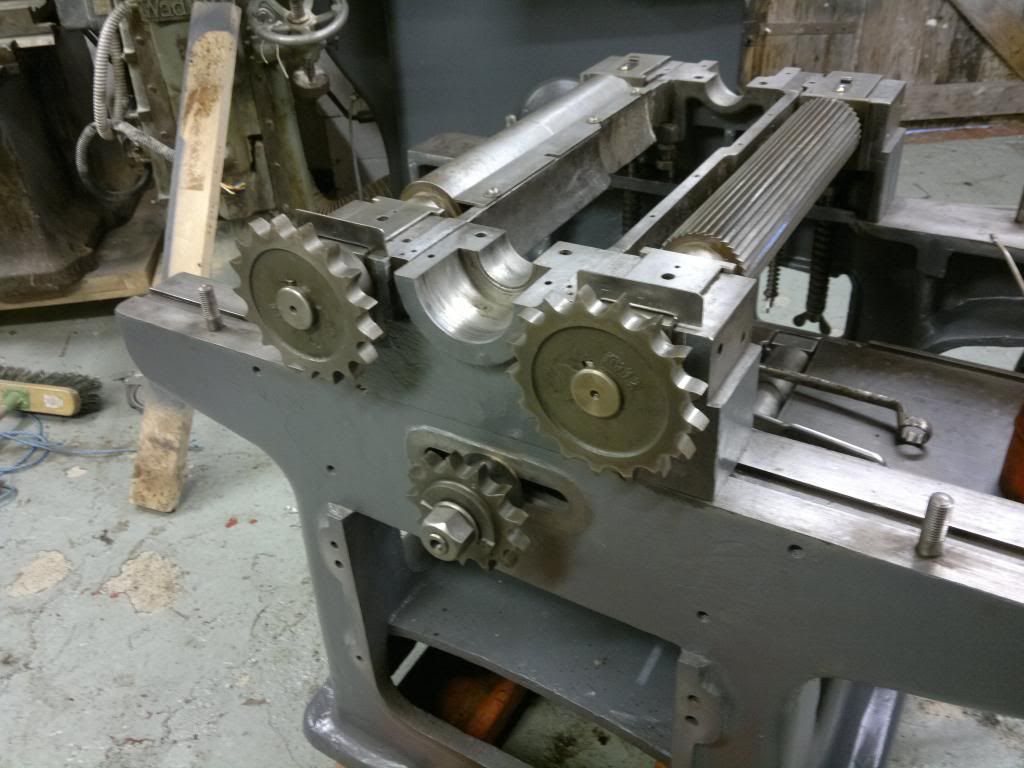

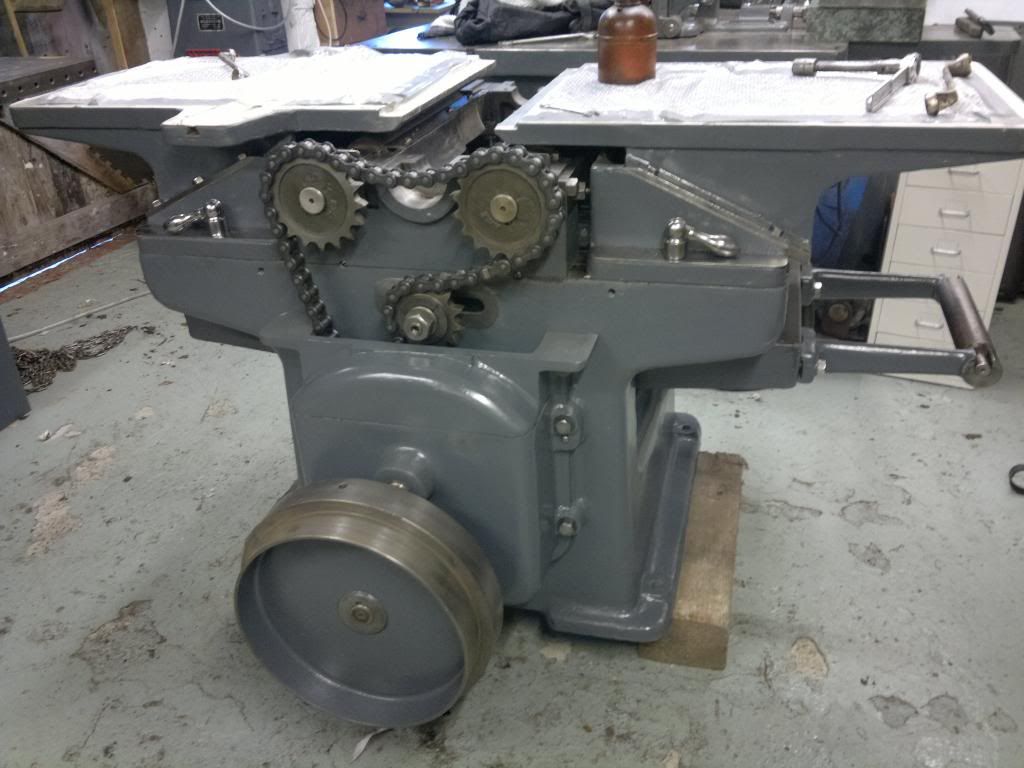

a while ago I told you about my bts500 that I bought from the bay, which was dropped just before I picked it up. today I had a guy come over who will be able to weld the broken cast for me. so I've started taking it apart, although i'd love to do a full strip down, I just need to get it working. it's not a beautiful looking machine, but it should be an excellent workhorse. I feel like a strip down to some extent will be needed to remove rust, grime and the like. I need to look back and see what your overnight bath is all about, presumably not matey. I may well have some questions for you regarding bearings, nuts etc. I have a wadkin cc to get working, and a 100yr old planer thicknesser to do a total restore on. (maybe in 40yrs when I retire) I like to keep an eye on what you are doing as it gives me a bit of encouragement to get on with mine (usually to the detrement of the work I should be getting on with) you're currently our equivalent of jack (tool613). keep up the good work, looking forward to using them?

nathan