ByronBlack

Established Member

New year, new project (or three)

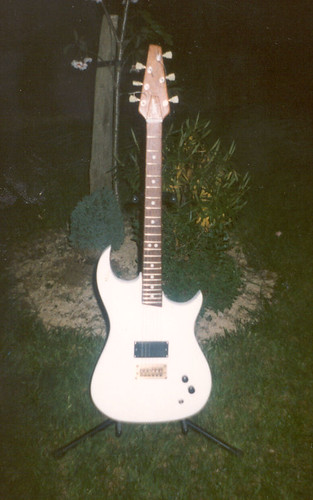

Here's a couple of pics of my latest project. The walnut explorer shape body was premade and purchased from ebay, I'm going to be making the neck for this one. The other guitar is one of my own designs, the body is made from english yew and topped with some lovely figured maple, I've ordered a pre-made neck for this one.

The reason for the pre-made components is two fold. The first being I need the guitars quite quickly, as one is a for a mate who gigs regularly and has some recording due in about a months time, and I also need a new guitar quite quickly. Secondly, the parts were cheaper than I could make them and represented a great bargain.

The third guitar project which I'm currently preparing the timber for will all be completed myself bar the pre-slotted fingerboard.

Both guitars are for rock/metal and will feature humbuckers and maybe some on-board effects such as compression and distortion.

The other picture shows some walnut laminates which will be the neck for the explorer. I've clamped them together dry and left them indoors for a couple of weeks to settle. I'll then glue together and square up and leave to settle for another week or so before attaching the fingerboard and carving the neck profile ('59 les paul for those interested).

Hopefully it won't be too long before I can show some more progress, but i'm hamstrung at the moment while I wait for parts and materials.

Neck laminates

Walnut Explorer

Elm & Maple Custom

Ditto

Another shot of the explorer body

Here's a couple of pics of my latest project. The walnut explorer shape body was premade and purchased from ebay, I'm going to be making the neck for this one. The other guitar is one of my own designs, the body is made from english yew and topped with some lovely figured maple, I've ordered a pre-made neck for this one.

The reason for the pre-made components is two fold. The first being I need the guitars quite quickly, as one is a for a mate who gigs regularly and has some recording due in about a months time, and I also need a new guitar quite quickly. Secondly, the parts were cheaper than I could make them and represented a great bargain.

The third guitar project which I'm currently preparing the timber for will all be completed myself bar the pre-slotted fingerboard.

Both guitars are for rock/metal and will feature humbuckers and maybe some on-board effects such as compression and distortion.

The other picture shows some walnut laminates which will be the neck for the explorer. I've clamped them together dry and left them indoors for a couple of weeks to settle. I'll then glue together and square up and leave to settle for another week or so before attaching the fingerboard and carving the neck profile ('59 les paul for those interested).

Hopefully it won't be too long before I can show some more progress, but i'm hamstrung at the moment while I wait for parts and materials.

Neck laminates

Walnut Explorer

Elm & Maple Custom

Ditto

Another shot of the explorer body