with my detail spindel gouge.

When try to use the tool the tool cuts very agresively. I start with the bevel rubbing the work piece. I raise the handle of the tool very very slowly until so,e but little very fine dust is coming off the tip. When raising the handle kust a hair more a very nice and thin shaving ribbon comes shooting off and with in a fraction of a second the gouge has turned away a deep cove.

When trying to create a bead (which is very difficult not to end up with only a thin stem) as soon as you get to the sides of the bead the tool catches on the side of the bead and creates a spiral about 1.5 mm deep.

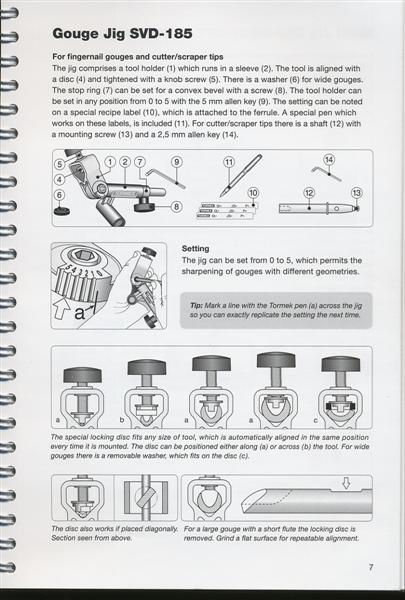

What am I doing wrong. The gouge is sharpened for the first time on the tormek. I used setting 2 on the SVD-185 and the on the TTS100 the middle depth gauge in combination with the hole nearest the to wheel which seemed to match the factory grind best.

When try to use the tool the tool cuts very agresively. I start with the bevel rubbing the work piece. I raise the handle of the tool very very slowly until so,e but little very fine dust is coming off the tip. When raising the handle kust a hair more a very nice and thin shaving ribbon comes shooting off and with in a fraction of a second the gouge has turned away a deep cove.

When trying to create a bead (which is very difficult not to end up with only a thin stem) as soon as you get to the sides of the bead the tool catches on the side of the bead and creates a spiral about 1.5 mm deep.

What am I doing wrong. The gouge is sharpened for the first time on the tormek. I used setting 2 on the SVD-185 and the on the TTS100 the middle depth gauge in combination with the hole nearest the to wheel which seemed to match the factory grind best.