Chris_belgium

Established Member

- Joined

- 7 May 2006

- Messages

- 272

- Reaction score

- 0

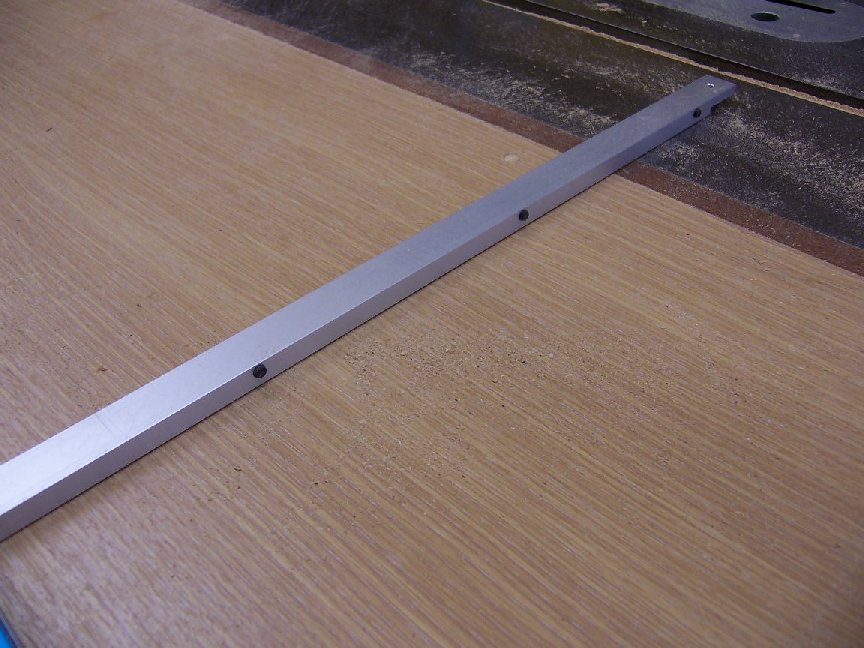

I'm looking to purchase a mitre gauge either a kreg or a incra system. Problem is my table saw has a triangular shaped mitre slot. I suppose the mitre slot bar with either system would work, but there would be a very small point of contact only at the top of the triangle, would like to hear some opinions about this, or even better some actual experiences with triangular mitre slot?