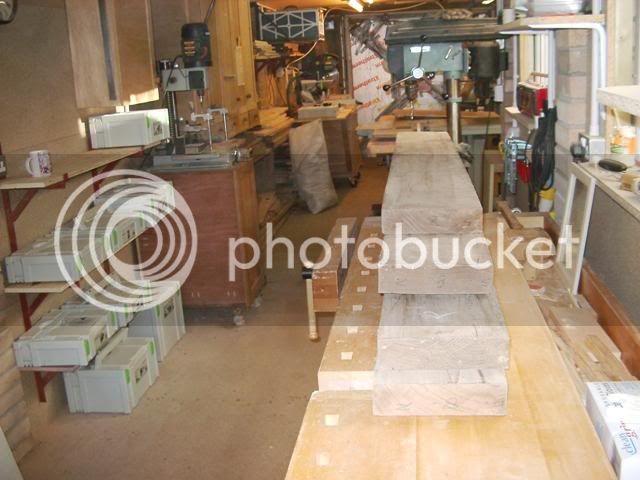

Up nice and early Monday and started the tool cabinet. First thing was to sort out some Indonesian Rosewood for the main frame.

Four nice big chunks should do to start with.

Having been supplied all the dimentions from Chris (Waterhead37) it was just a matter of slicing through on the table saw and doing the final trim on the PT

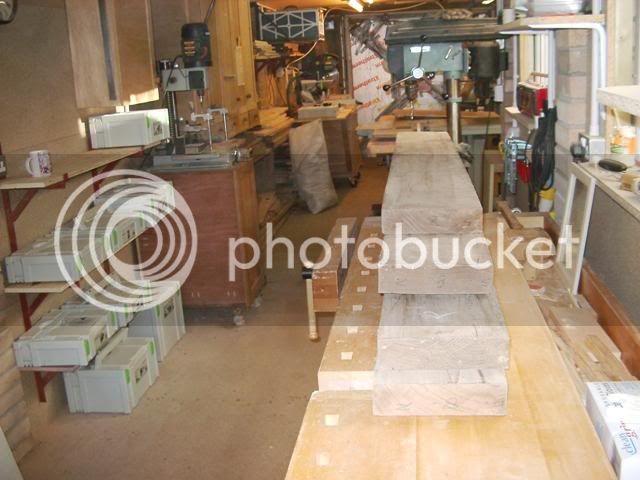

The styles are 2 3/4" X 2" with the base being 36" long and the top section 44" long. The top is slightly shorter than Chris's because I don't have the head room.

The 2 3/4" x 2" might seem a little chunky, but I can assure you it doesn't look out of proportion when you see the real thing.

The rails are 2 3/4" X 1 3/4", this allows for a 1/4" reveal on the outside, this is another thing that looks right on the real thing.

Spent today making out the styles for the mortises, then did the upper and lower side panels. Once the machine was set up it didn't really take all that long.

All in all a good days work.

Hopefully tomorrow I can size the upper and lower stretchers and get the mortises done for them. The plan for next week is to concentrate on the tenons.

Four nice big chunks should do to start with.

Having been supplied all the dimentions from Chris (Waterhead37) it was just a matter of slicing through on the table saw and doing the final trim on the PT

The styles are 2 3/4" X 2" with the base being 36" long and the top section 44" long. The top is slightly shorter than Chris's because I don't have the head room.

The 2 3/4" x 2" might seem a little chunky, but I can assure you it doesn't look out of proportion when you see the real thing.

The rails are 2 3/4" X 1 3/4", this allows for a 1/4" reveal on the outside, this is another thing that looks right on the real thing.

Spent today making out the styles for the mortises, then did the upper and lower side panels. Once the machine was set up it didn't really take all that long.

All in all a good days work.

Hopefully tomorrow I can size the upper and lower stretchers and get the mortises done for them. The plan for next week is to concentrate on the tenons.