About 2 years ago I bought some American black walnut to turn into a tool chest. As various Christmases and birthdays went buy the pile got smaller and smaller, but as I've got 2 weeks off work I've decided to bite the bullet and get a move on.

The idea is to make a machinist's chest big enough to take all my measuring and marking tools, chisels and small handplanes - I've been using philly's for inspiration. The final dimensions will be about 12x12x20 ish, just the right size to fit in a space under my wall cabinets. It'll be entirely fitted out with drawers so I can put stuff on the top.

I started by planing up my (remaining) stock. Behind it you can see the veneer which I "borrowed" from my brother to make the panels with.

Then I got a bit carried away and ripped and crosscut the pieces to size. I'm using a coping bit in my router table to join the pieces. I got it for christmas ages ago, and this is the first time I've used it in anger.

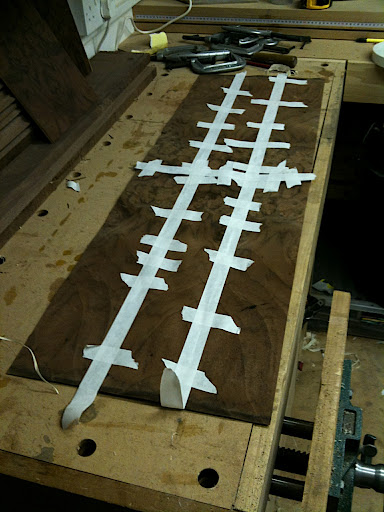

All the rails and stiles done:

Now cutting the matching parts on the rails:

I was a bit worries about breakout on the back side, but it seems ok when I tried the test piece, so I just went for it.

All the bits dry fitted together with the MDF panels:

Now, onto the veneering. I've only done this once before, so here goes. first I jointed it between two scraps:

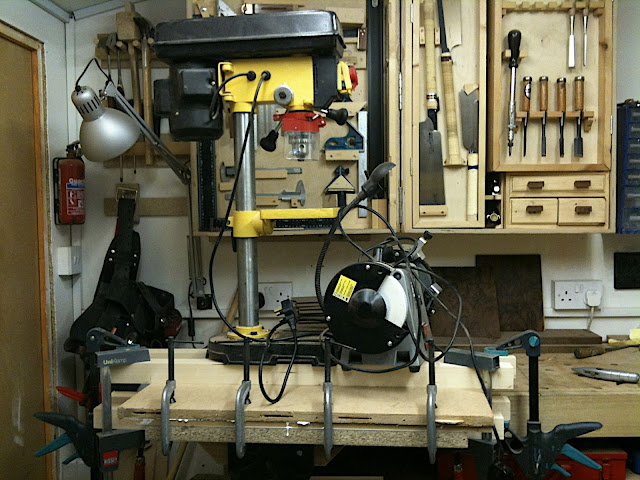

Then I joined two pieces together with veneer tape, then clamped it up with cauls and plenty of clamps

I'll take them out of the clamps this morning - fingers crossed!

The idea is to make a machinist's chest big enough to take all my measuring and marking tools, chisels and small handplanes - I've been using philly's for inspiration. The final dimensions will be about 12x12x20 ish, just the right size to fit in a space under my wall cabinets. It'll be entirely fitted out with drawers so I can put stuff on the top.

I started by planing up my (remaining) stock. Behind it you can see the veneer which I "borrowed" from my brother to make the panels with.

Then I got a bit carried away and ripped and crosscut the pieces to size. I'm using a coping bit in my router table to join the pieces. I got it for christmas ages ago, and this is the first time I've used it in anger.

All the rails and stiles done:

Now cutting the matching parts on the rails:

I was a bit worries about breakout on the back side, but it seems ok when I tried the test piece, so I just went for it.

All the bits dry fitted together with the MDF panels:

Now, onto the veneering. I've only done this once before, so here goes. first I jointed it between two scraps:

Then I joined two pieces together with veneer tape, then clamped it up with cauls and plenty of clamps

I'll take them out of the clamps this morning - fingers crossed!