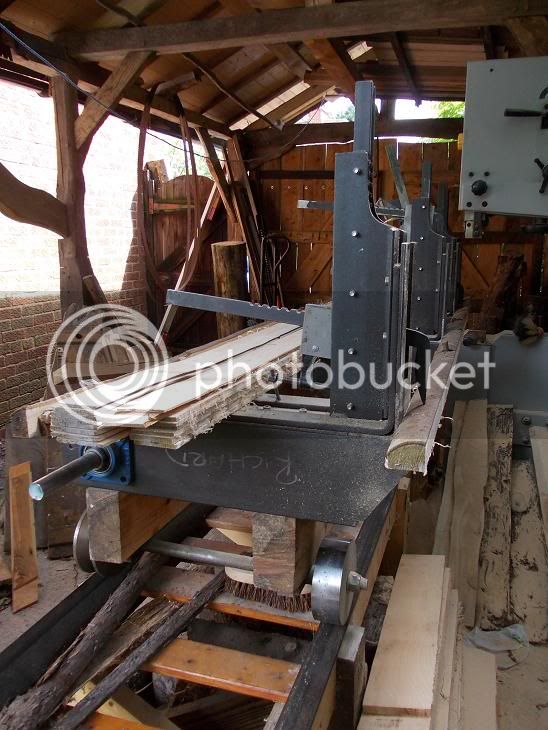

This would seem the way to go wouldn't it? Both angled rails. Yet all the photos, drawings and patent ap.s I've seen are like I have built; angled guide rail and flat load bearing rail - with brushes. And, to be honest, I don't know why. I thought I'd better do it that way as it seems tried and tested in the hope that the reason would become apparent in use. All that I can think is squaring to the blade is easier. That and it was very much cheaper to have three grooved wheels made than six.

The next one??? :lol: The gear of a sliding gate.... I did look into all sorts of things I might be able to salvage gears from, agricultural mostly, but where could I get four the same from? I looked at doing it with chains at one point, double vice style but finally settled on buying rack and pinions which weren't that much in the end, after shopping around.

It's a lot quieter than if I had done it with a circular saw - just normal bandsaw noise. The neighbours are very good. They put up with an awful lot from me what with that, chainsawing, the forge, swearing, etc.. But I have done things for them with it ... so they can't complain too much ... I hope.