Byron wrote:

keep seeing the little Stanley 75 Bullnose plane - what exactly is the purpose of this plane?

Small doorstop for a small door or paper weight.

Also, what plane is the one I need to make dado's, grooves and rebates. I used to own a Record combination plane but wasn't that comfortable using it - is there something else I should look at.

One option is a Stanley #45. Another is a #50 with extra blades. A #55 is overkill.

Also, the Record 778 (stanley 7: are these for just creating a rebate on the very edge of a board, or can they be used to create stopped groove/dado?

The #778/78 only has one size blade. Therefore it is only only adjustable for edges.

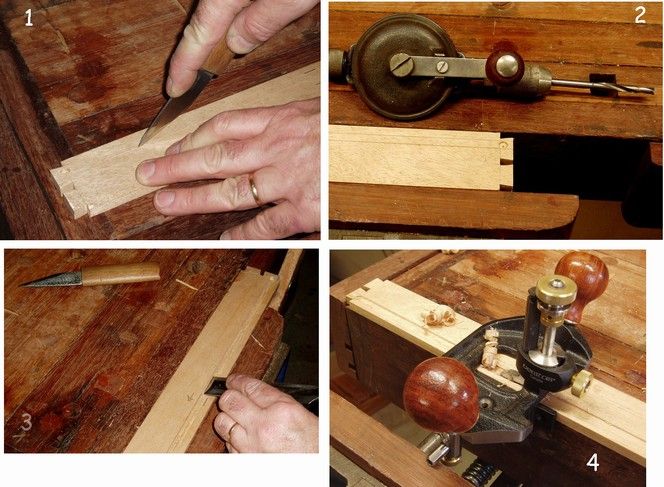

A stoped groove/dado can be made with a routerplane.

And finally, I see loads and loads of the wooden rebate/shoudler planes about - are these useful and will these allow me to adjust the width of a dado?

If you wish to adjust the width of a rebate, the planes of choice are the Stanley #79 side rabbet or the Stanley/LN #98/99 combo.

Regards from Perth

Derek