ok so it's not a new idea but i've just done it and it was relatively easy so hope this might help others:

Buy a cheap router from boot sale £5 - can get them new for £25 if it breaks from B&Q

take all the bits off

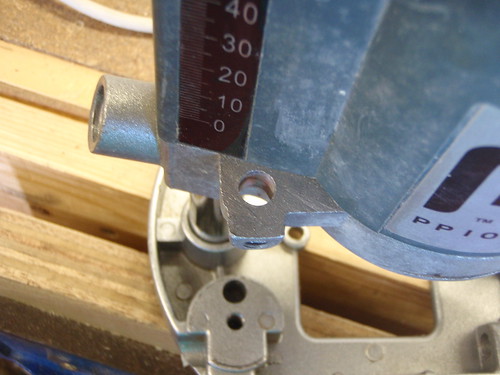

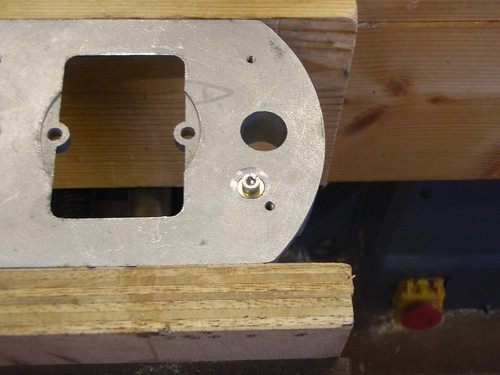

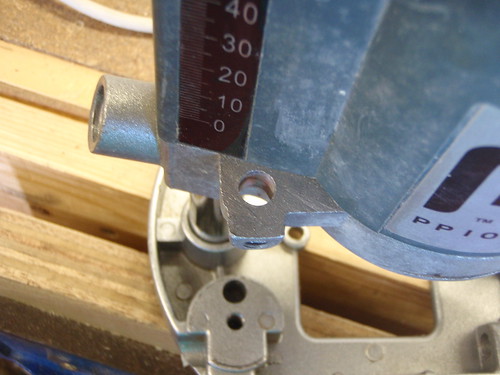

note how depth guage hold and depth stop hole line up

line up perfectly

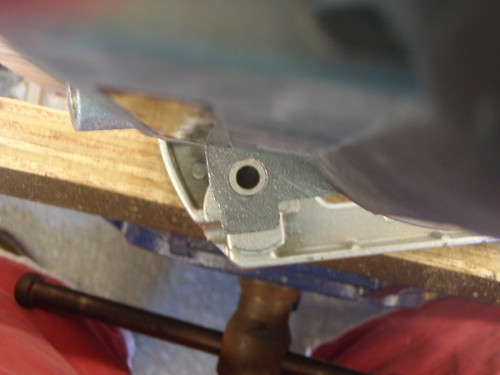

take off legs

don't forget nasty little grub screw that got stuck requiring purchase of screw extractor kit from screwfix - amazing piece of kit if you've not got one get one - anyway take out grub screw and use drift to knock out legs

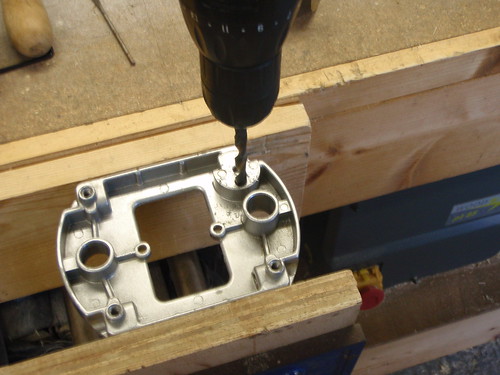

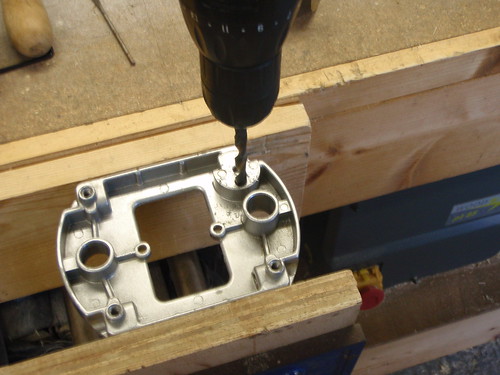

drill hole through base plat using depth stop hole as guide - its exactly the right size - 8mm

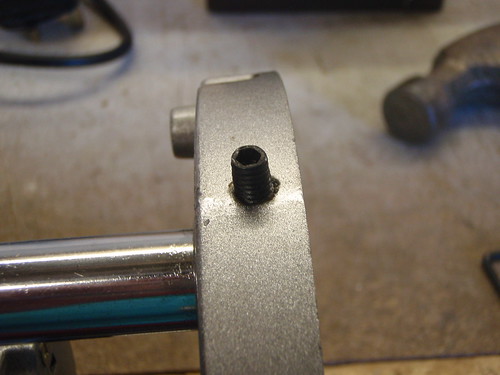

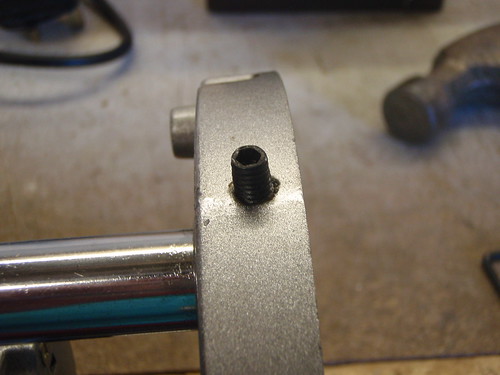

find bit of M8 threaded rod from tin of assorted bits of bolts and stuff flatten one edge of bolt so it sits flush against side of router

drill hole in other end of rod and glue in M4 allen head bolt (tried to thread it but the correct size hole for M4 is 3.3mm drill which I didn't have - and 3mm didn't work as I am cack - there's nothing wrong with Araldite - make sure you put a washer in between the rod and M4 bolt to stop the rod falling out the 8mm hole you drilled earlier

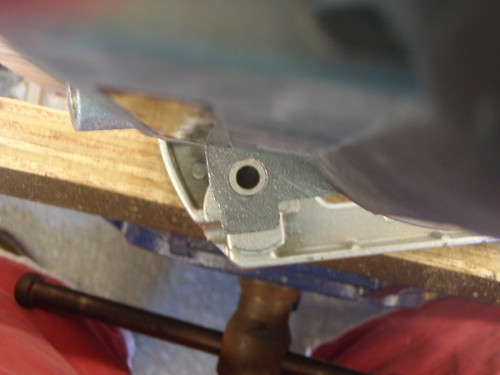

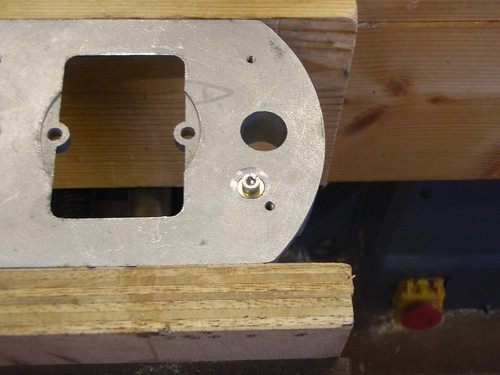

here's how it sits in the base (its a little proud but i reckon itll still be below my router plate surface - if not i can sink it a bit more

and here it is having just wound the router up - the allen key is sticking out the bottom -I'll have to make some winding handle later. the nut is just visible just below and to the right of the '0' on the depth scale - it's just glued in/on.

That's it - thanks to all for the help on the 'holes for tapping' thread just a bit further down than this one

Sorry to mods if too many photo's - I left out half of them

Cost - £5 and a screw extractor set!

now I just need to build a router table to put it in!!!

Thanks for looking

Pete

Buy a cheap router from boot sale £5 - can get them new for £25 if it breaks from B&Q

take all the bits off

note how depth guage hold and depth stop hole line up

line up perfectly

take off legs

don't forget nasty little grub screw that got stuck requiring purchase of screw extractor kit from screwfix - amazing piece of kit if you've not got one get one - anyway take out grub screw and use drift to knock out legs

drill hole through base plat using depth stop hole as guide - its exactly the right size - 8mm

find bit of M8 threaded rod from tin of assorted bits of bolts and stuff flatten one edge of bolt so it sits flush against side of router

drill hole in other end of rod and glue in M4 allen head bolt (tried to thread it but the correct size hole for M4 is 3.3mm drill which I didn't have - and 3mm didn't work as I am cack - there's nothing wrong with Araldite - make sure you put a washer in between the rod and M4 bolt to stop the rod falling out the 8mm hole you drilled earlier

here's how it sits in the base (its a little proud but i reckon itll still be below my router plate surface - if not i can sink it a bit more

and here it is having just wound the router up - the allen key is sticking out the bottom -I'll have to make some winding handle later. the nut is just visible just below and to the right of the '0' on the depth scale - it's just glued in/on.

That's it - thanks to all for the help on the 'holes for tapping' thread just a bit further down than this one

Sorry to mods if too many photo's - I left out half of them

Cost - £5 and a screw extractor set!

now I just need to build a router table to put it in!!!

Thanks for looking

Pete