santiniuk

Established Member

Hi folks,

My wood turning addiction had to take a back seat for the last couple of months. My re-occuring Tennis elbow combined with a dodgy back made me less than mobile and even worse It was cold in the garage :lol:

But.... a colleague at work offered me some Cherry tree logs last week so I obviously couldnt say no.....

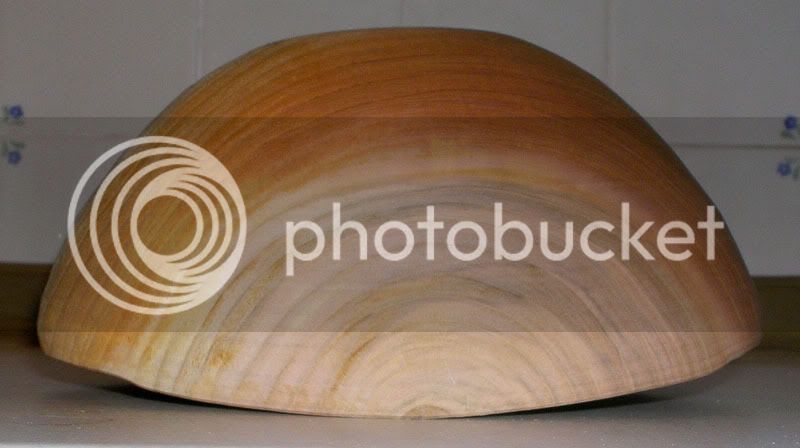

I'm after advise. From the attached pictures what would be the best method of storing. The large logs are just over 12" in diameter and the smaller ones just over 6". They are all about 26" long.

Would it be best to split down the centre and seal the ends or cut into small sections and seal smaller pieces and seal both ends.

I have read loads of posts but when it comes to it I'm wondering whats the best way to store them without waiting years to actually use them :shock:

Any special recommendations for Cherry ?

Thanks, I'm looking forward to joining in again with the forum activity.

Cheers

Shaun

My wood turning addiction had to take a back seat for the last couple of months. My re-occuring Tennis elbow combined with a dodgy back made me less than mobile and even worse It was cold in the garage :lol:

But.... a colleague at work offered me some Cherry tree logs last week so I obviously couldnt say no.....

I'm after advise. From the attached pictures what would be the best method of storing. The large logs are just over 12" in diameter and the smaller ones just over 6". They are all about 26" long.

Would it be best to split down the centre and seal the ends or cut into small sections and seal smaller pieces and seal both ends.

I have read loads of posts but when it comes to it I'm wondering whats the best way to store them without waiting years to actually use them :shock:

Any special recommendations for Cherry ?

Thanks, I'm looking forward to joining in again with the forum activity.

Cheers

Shaun