Hi,

I'm in the process of planning a very simple, first, workbench as my first (ever!) woodworking project.

I'm probably going to go for a simple MDF/hardboard top to keep things nice and simple, with two vices front left and on the end using cast iron woodworking Record style.

My questions (so far!) are:

1. I've read up about the pros cons of round vs square and have opted to go for round as I think this will be simplest and easiest with my choice of work top. Do I need to taper the round dog holes in the same way as I've read you need to do for square dog holes i.e. by approx. 2 degrees towards the end vice?

2. Also, and this is probably a very silly newbie question, but how do you stop the round dogs from dropping through the dog holes when inserted (with square ones I've seen people make use of a wood/metal spring to stop this)???

3. What's the best way of attaching the MDF/hardboard worktop to the base?

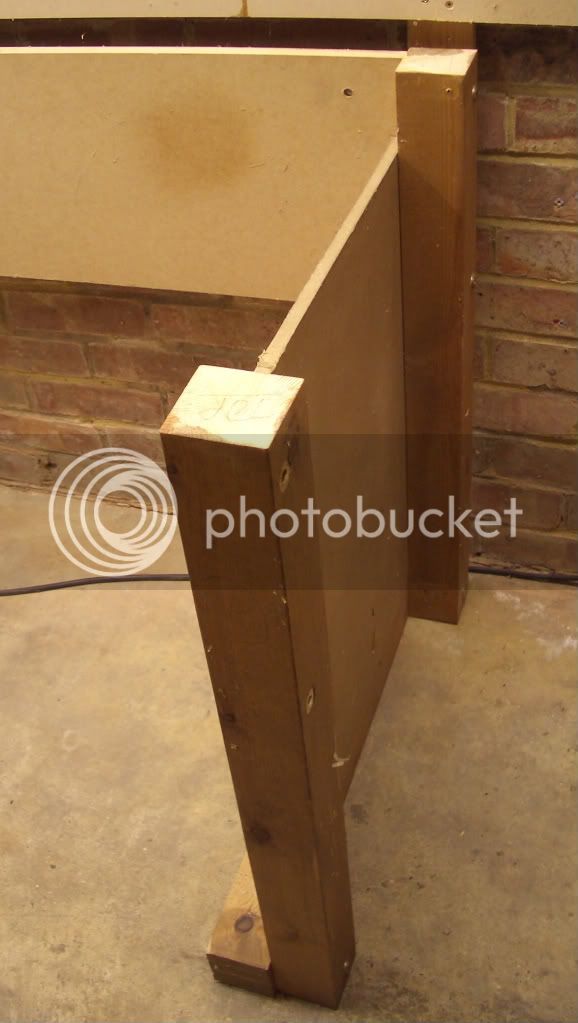

4. Which would be better, sled feet or posts end grain on to the floor?

Apologies for all the questions!

Jonny

I'm in the process of planning a very simple, first, workbench as my first (ever!) woodworking project.

I'm probably going to go for a simple MDF/hardboard top to keep things nice and simple, with two vices front left and on the end using cast iron woodworking Record style.

My questions (so far!) are:

1. I've read up about the pros cons of round vs square and have opted to go for round as I think this will be simplest and easiest with my choice of work top. Do I need to taper the round dog holes in the same way as I've read you need to do for square dog holes i.e. by approx. 2 degrees towards the end vice?

2. Also, and this is probably a very silly newbie question, but how do you stop the round dogs from dropping through the dog holes when inserted (with square ones I've seen people make use of a wood/metal spring to stop this)???

3. What's the best way of attaching the MDF/hardboard worktop to the base?

4. Which would be better, sled feet or posts end grain on to the floor?

Apologies for all the questions!

Jonny