I know guys like Mike K are really good with this stuff - how long does it take to learn?

You are too kind, but I think I am still a novice at SU, and it is a perishable skill. I had a lot of AutoCAD experience with 2D engineering drawings, but SU is my first attempt at 3D. I was making simple cabinets in about 30 minutes the first time I used SU.

Everything I learned came from YouTube, mostly from Justin Geis, The SketchUp Essentials. Justin has hundreds of short videos that go into detail on every feature of SU, including the free Make 2017 version that I use.

https://www.youtube.com/channel/UCJafTeHBrRBL9tS-S-kRbpw

I was able to model my shop, with all of the equipment, in about four hours. This included baselining the footprint, searching the 3D Warehouse for the 1:1 SU models for as much of the equipment as I could find, and going back to the SU tutorials to determine how to do something I had forgotten. I already finished the miter saw workstation, so I was able to import it as a component into the shop layout. As a result of seeing how it fit in the model, I made a few adjustments to the workstation to make the shop less cramped.

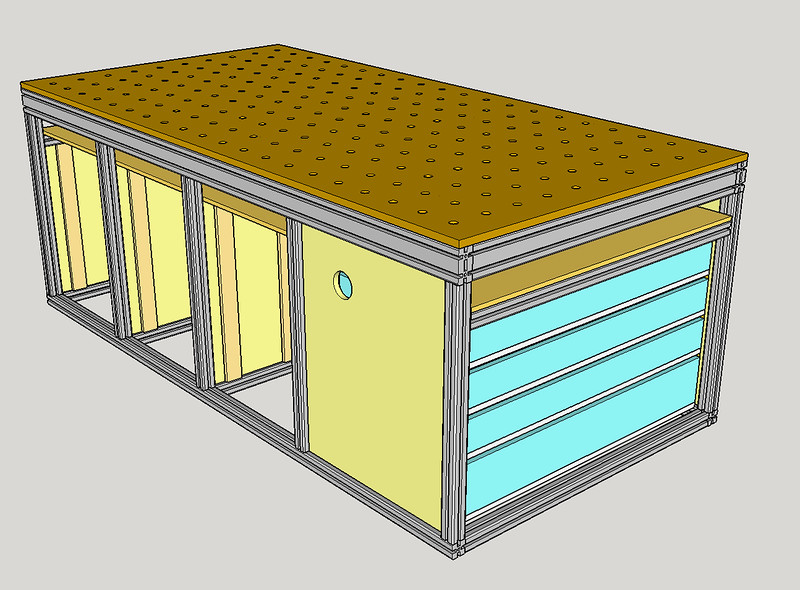

When I decided to make a mobile MFT-style workbench, I created a SU model. I think the workbench took me two hours to create, and another two hours, or so, to modify it by adding more drawers and surface support beams.

Here is the SU model of my workbench, not including the wheels, sliding shelves and drawers on the side, or the drawer fronts for the end drawers.

Here is the actual workbench as of two hours ago. I still have a lot of work to do, such as make the holes in the Valchromat top, but I was able to make changes to the design with SketchUP before buying more plywood or aluminum extrusion. Please excuse the clutter in the basement. It is also a work in progress.

The original design had three full width drawers on the end, at 100mm, 150mm, and 212mm high. Over the weekend, I changed my mind and made three 100mm high drawers and one 150mm high drawer. After another inventory of the things I know I will put in the drawers, I need three 100mm high drawers. I only had three sets of 500mm full-extension drawer slides, so I ordered more today and pre-drilled the holes for the slides.

I installed the 400mm full-extension drawer slides at the bottom along the side openings, since these were easy to install while the partitions were out. When I figure out which tools I want in the workbench, I can add the remaining slides.