MooreToolsPlease

Established Member

- Joined

- 17 Sep 2006

- Messages

- 366

- Reaction score

- 0

Evening all,

I'm after a reasonably priced mitre saw to setup for a joint I need to do on the window frames I make. The company I make them for is introducing a standard size of windows and as they are standard sizes, is wanting them cheaper than the bespoke ones. Which is fair enough.

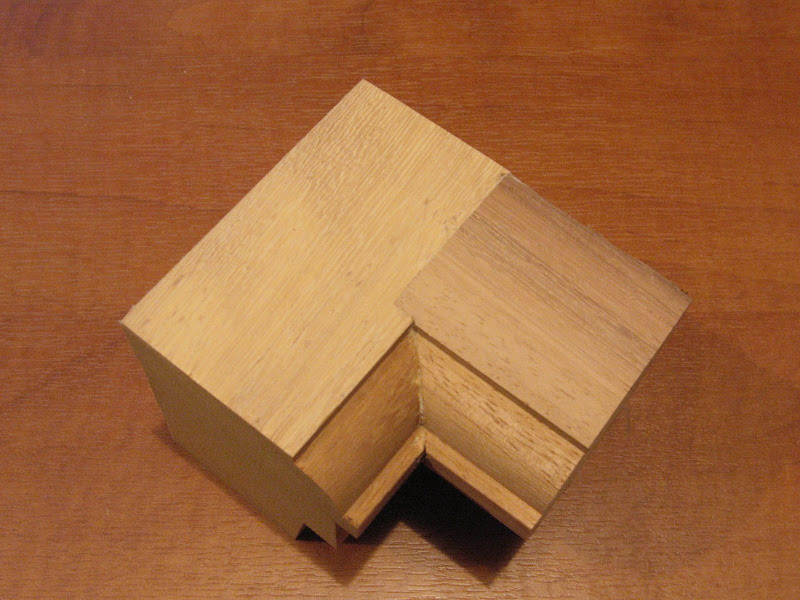

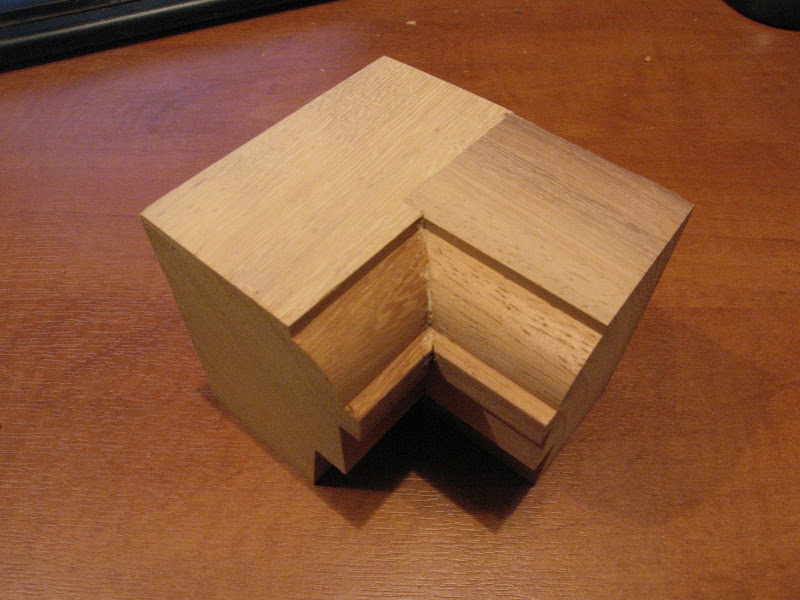

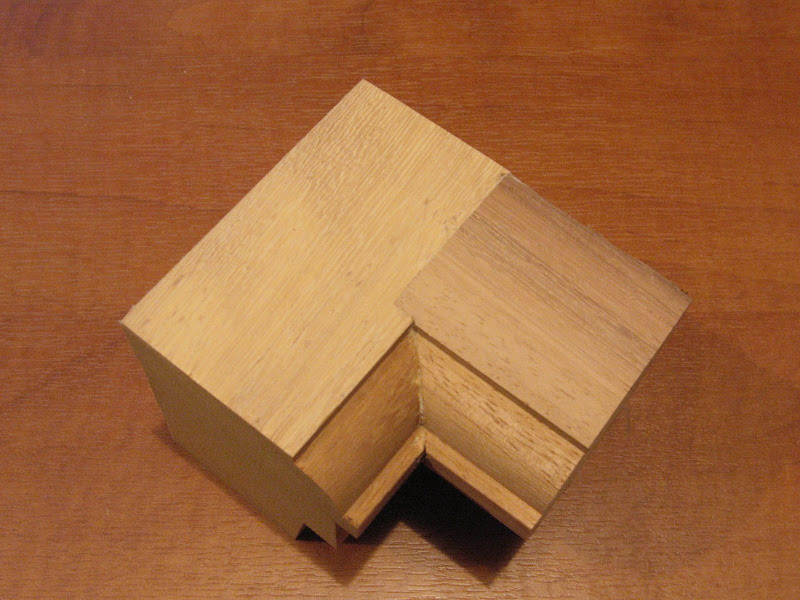

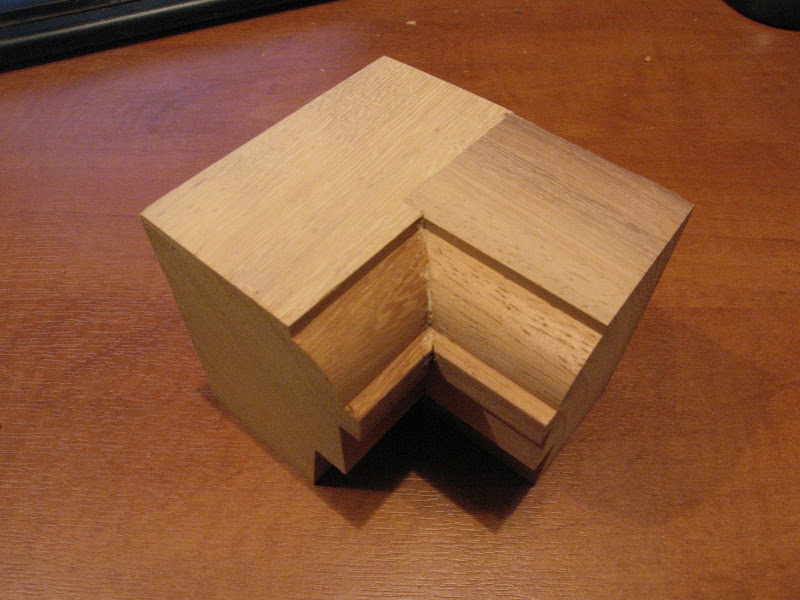

I've attached a photo of the joint and how I want to do it, basically it is a masons mitre.

I normally do the bespoke frames on the 4 head tenoner, and then run them through the spindle after.

I can make quite a big saving by buying in the material pre moulded, and then do the masons mitre for the joints.

I'll need to set up 3 of them to do the various operations, with a spacer for the material to sit on depending on whether it is the cill section @ 69 thick or the heads and jambs at 57 thick.

I've just picked up the 8 1/4" metabo slider but it isnt big enough, and the depth stop for trenching is micky mouse.

what saws does the forum have which have a good trenching facility, and reasonably priced?

Thanks[/img]

I'm after a reasonably priced mitre saw to setup for a joint I need to do on the window frames I make. The company I make them for is introducing a standard size of windows and as they are standard sizes, is wanting them cheaper than the bespoke ones. Which is fair enough.

I've attached a photo of the joint and how I want to do it, basically it is a masons mitre.

I normally do the bespoke frames on the 4 head tenoner, and then run them through the spindle after.

I can make quite a big saving by buying in the material pre moulded, and then do the masons mitre for the joints.

I'll need to set up 3 of them to do the various operations, with a spacer for the material to sit on depending on whether it is the cill section @ 69 thick or the heads and jambs at 57 thick.

I've just picked up the 8 1/4" metabo slider but it isnt big enough, and the depth stop for trenching is micky mouse.

what saws does the forum have which have a good trenching facility, and reasonably priced?

Thanks[/img]