Philly":1qwob8ps said:

Dado's are mostly used to cut grooves (or Dado's........) during which the cutter is buried in the work. I fail to see how this is more dangerous than a cut where the cutter goes right through the workpiece exposing the cutter the whole time. Hmm....

Except at the start and end of the cut when it's not buried in the work........... As you should well know the issue is one of guarding and without a SUVA-type crown guard how does one guard a blade in a table saw which by its design and use precludes the use of a riving knife? My biggest gripe is the constant encouragement to use cutters sans guarding when there are alternative and safer solutions to hand. And why? To emulate a star of stage, screen (and ER room) in the US of A :roll:

Digit":1qwob8ps said:

And Philly is quite correct as well IMO, as he says, a Dado head is buried in the wood for most of the time so you can't cut yourself.

Why, then, did the one recent accident I've read which involved a stacked-saw dado head on a table saw happen at all? The operator was using a stacked saw dado head to make a series of housing joints in library shelving on a table saw. There was a kickback (remember that dado heads have rising teeth as well) probably caused by the workpiece tipping as it exited the machine, which had no rear run-off table). The operator overbalanced and in putting their hand out to prevent injury inadvertently came into contact with the exposed (unguarded) stacked saw dado set. It cost that person three fingers (right hand) and a lot of painful surgery. It was also avoidable.

Philly":1qwob8ps said:

As for chip limiters, my Freud set is fully equipped with limiters.

You are obviously confusing

chip limitation design, as applied to split 2-part grooving/safety dado heads and so-called

anti-kickback outer blades as shown on the Freud set. They are most definitely

not the same and the Freud set is nowhere near as benign as a proper chip-limitation design in the event of a contact (hand or material). If you want to understand what the term "chip limitation design" means I suggest that you read

this document which explains it further then you'll better understand my comments.

Philly":1qwob8ps said:

So the "a dado is much more savage than a "insert your tool here"" argument is pretty dead in the water.

Really? The stacked dado set you are referring to is most certainly not of chip limitation design and like all such sets will tend to draw the hand in rather than expel it should there be hand to tool contact. I've seen photographs of the amount of damage a dado head can cause to a hand and it isn't pretty. Also, unlike the smaller laceration or clean amputation which occurs with a chip limiter cutter set or a saw blade the damage is much more difficult to repair. Multiple lacerations can be dealt with by stitches and/or reconstructive surgery, clean amputations are also repairable (and on that subject perhaps Dan Tovey might like to comment), although in neither case can subsequent full use be guaranteed and in both cases partial loss of use and loss of sensation for the rest of one's life is a probable outcome. This I know from painful personal experience, fortunately only laceratiuons and not with a dado head. A dado head contact, on the other hand, tends to remove a lot more and pulverise it. It often makes an unrepairable injury and results in surgical amputation.

Digit":1qwob8ps said:

And if you buy a modern table saw it will probably come with a full fence and greatly increased risk of a kickback, yet years ago short fences were the norm and I certainly never experienced it on older machines.

I think that the differences are in the DIY sector where there are some appalling cheap and nasty solutions around - many based on the so-called flagship Unisaw design, a saw which was out of date (in safety terms) by the time it was withdrawn from the British market in the 1970s. All the current industrial machines I know come with a sliding short-long position rip fence, e.g. the Felders, Hamers, Roblands, Rojeks, etc It is just a pity that those people importing from the Far East cannot be *rsed to specify a better rip fence design )or fot that matter offer optional SUVA-type guards). After all they are available, as evidenced by this design from Grizzly:

(That's the rip fence fitted to the G0623X 10in sliding table saw which costs around £1300 in the USA)

Digit":1qwob8ps said:

What greatly surprises me is the fact that Dado sets are freely available to be fitted to radial arm saws. How our masters ever came to the conclusion that it was safe to use them on a RAS but not a table saw utterly baffles me!

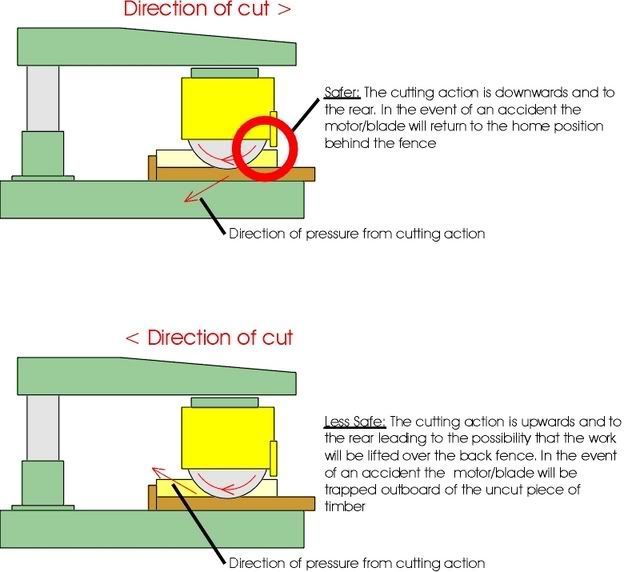

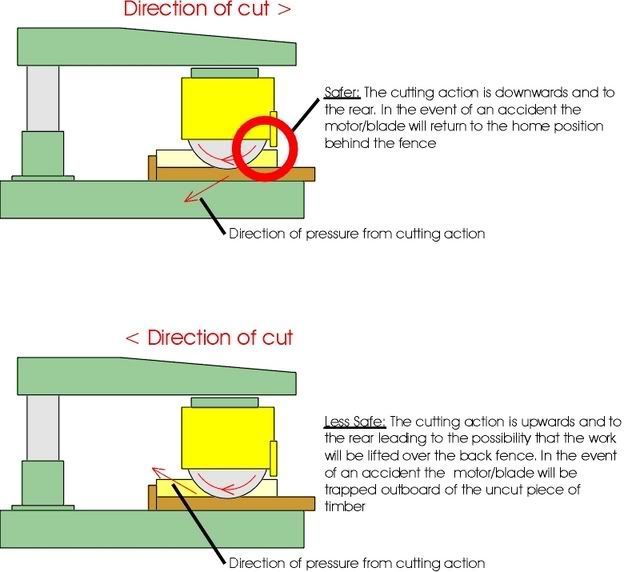

Roy, have you ever used a radial arm saw for prolonged periods? They are not without their dangers, however, using a dado head (even a stacked saw dado head) on them is arguably much safer than using a dado head on a table saw. Firstly your right hand is always on the handle controlling the cut. The left hand is positioned away from the blade to the left of the cutter and the dynamics of the cut when used correctly doing a pull cut mean that the workpiece is automatically pushed back towards the rear fence and downwards (see below). In addition, should the operator let go of the handle the head is supposed to be set-up with an automatic return mechanism which returns it to a safe place to the rear of the fence. The upper drawing in this diagram should explain the situation I've just described:

With a properly set nose guard and side skirts the dado head on a radial arm saw is very well guarded as opposed to the Norm approach of an exposed blade without any form of guarding. Which is the safer approach?

Scrit