gidon

Established Member

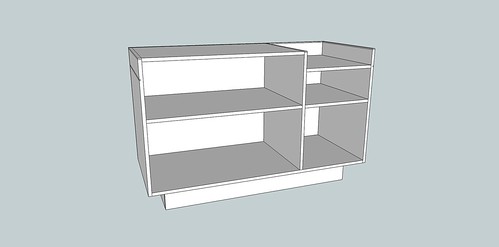

Decided easier to start a new thread for the shop counter (see previous thread if you're interested.)

Can't work out how to build this for assembly in my shop so going to have to shift the thing assembled! 1.4m wide x 900mm high (800mm till) x 600mm deep.

I blame Tom and Simon for the birthday present (and what seemed like a good'ish deal) to myself .

.

A question on the Domino - the 5x30 dominoes are extremly tight in the MDF - particuarly the face. Is that normal. I have to used a vice grip to remove them which makes a dry fit very tricky? Are there any tips?

Also any tips on carcass assembly with the Domino - you can see I'm all ready to go - I have some spacers for the shelves (I should make the shelves adjustable but haven't planned ahead and not sure how to do it easily). I may add a drawer at a later stage. The front panel will be rebated in with solid Walnut trim as before.

Again details on Flickr:

Cheers

Gidon

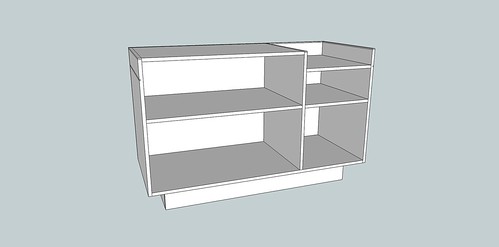

Can't work out how to build this for assembly in my shop so going to have to shift the thing assembled! 1.4m wide x 900mm high (800mm till) x 600mm deep.

I blame Tom and Simon for the birthday present (and what seemed like a good'ish deal) to myself

A question on the Domino - the 5x30 dominoes are extremly tight in the MDF - particuarly the face. Is that normal. I have to used a vice grip to remove them which makes a dry fit very tricky? Are there any tips?

Also any tips on carcass assembly with the Domino - you can see I'm all ready to go - I have some spacers for the shelves (I should make the shelves adjustable but haven't planned ahead and not sure how to do it easily). I may add a drawer at a later stage. The front panel will be rebated in with solid Walnut trim as before.

Again details on Flickr:

Cheers

Gidon